CNC machine parts

HMI & PLC

Electrical devices

Posts

plasma F2100B

type

status

date

slug

summary

tags

category

icon

password

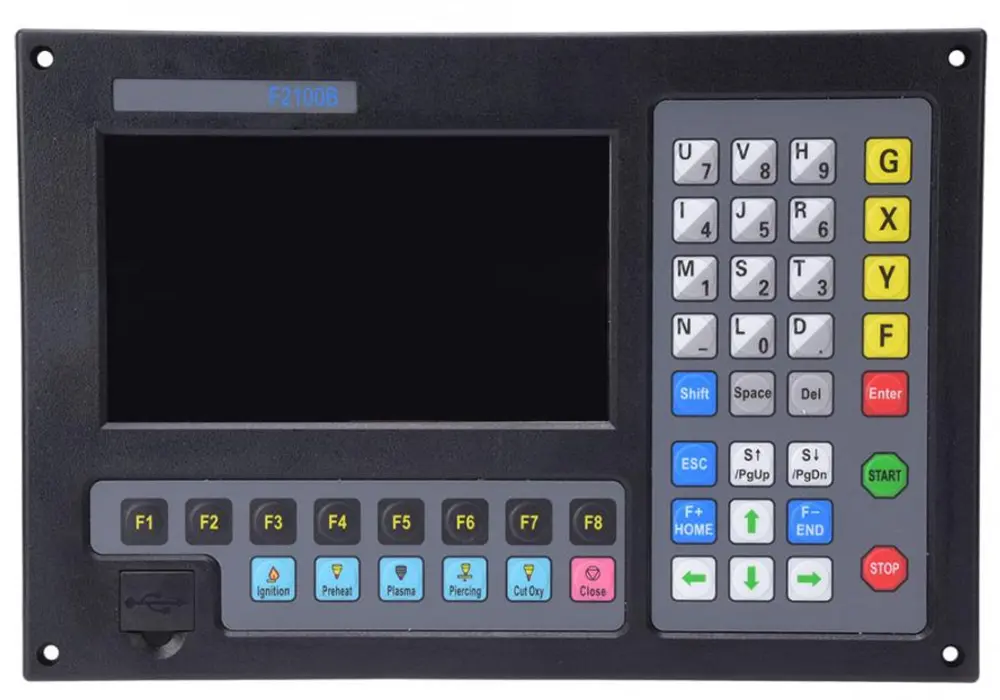

The Fangling F2100B plasma controller is a specific model of plasma control system offered by Fangling Technology Co., Ltd. It is designed to provide precise control and operation for plasma cutting machines. The F2100B plasma controller offers advanced features and functionality to optimize the performance of plasma cutting processes.

Key features of the Fangling F2100B plasma controller may include:

- High-precision control: The controller is equipped with advanced algorithms and control mechanisms to ensure accurate and consistent plasma cutting results.

- User-friendly interface: It may have an intuitive and user-friendly interface, allowing operators to easily navigate and set various parameters for the plasma cutting process.

- Automatic arc voltage height control (THC): The F2100B plasma controller may include THC functionality, which automatically adjusts the torch height to maintain the optimal cutting distance, ensuring clean and precise cuts.

- Cutting parameter customization: It may allow operators to set and customize various cutting parameters such as cutting speed, pierce time, and torch delay, providing flexibility to adapt to different cutting requirements.

- Integrated I/O interfaces: The controller may feature multiple input/output interfaces to connect with other components of the plasma cutting system, such as torch height controllers, limit switches, and safety devices.

- Diagnostic and troubleshooting capabilities: It may provide diagnostic tools and error reporting functions to facilitate quick identification and resolution of any issues that may arise during operation.

Please note that specific features and specifications of the Fangling F2100B plasma controller may vary. For detailed information and technical specifications, it is recommended to refer to the official documentation or contact Fangling Technology Co., Ltd. directly.

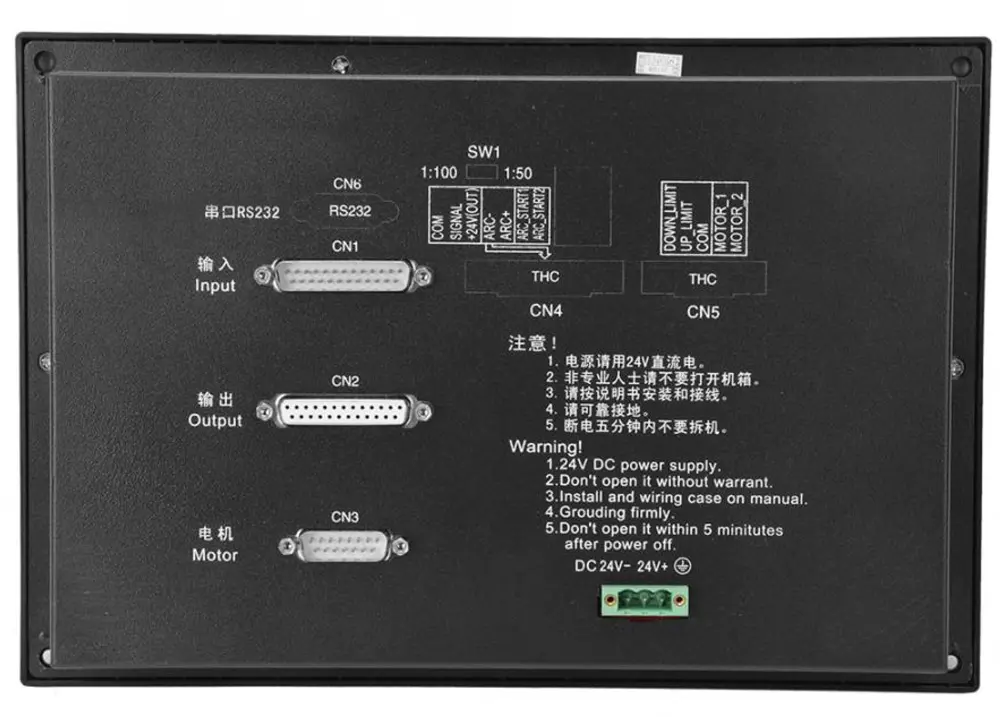

Technical indicator● Control Axis: 2-axis linkage● Control accuracy: +/-0.001mm● Coordinate range: +/- 99999.99mm● Max pulses: 200 kHz.● Max speed: 15,000 mm/m● Max lines of code: 80,000lines● Max size of single code file: 4M● Time resolution: 10ms● Working Voltage: DC +24V direct-current power input, power > 80W。● Working Temperature: -10℃~+60℃. Relative Humidity, 0~95%.● Max power of drive arc THC motor: 45W (suitable for models with “T”). If you need more power, you can select a maximum value: 200W.

Controller Interface● DB15 pins SMA Male interface of 2 axes of the motor drive.● DB25 pins SMA Female interface of 16 channels optoelectronic isolation output ports max backflow current 300mA.● DB25 pins SMA Male interface of 16 channels optoelectronic isolation input ports, max output current 300mA.● USB interface on the front panel, for the convenience of transmitting cutting code.● Extend IO input/output ports, PWM input ports, and analog input ports.● Optional standard DB9 core male serial port RS232 interface.

Hardware Configuration● Monitor:7 inch, 800*480, high definition 16 million colors, and high brightness LCD● Memory: 64M SDRAM● Program space available for user: 256M electronic hard disk● CPU frequency: 400MHz● USB: USB 1.1 front interface, at least 16GB U disk supportable● Keyboard: PCB keyboard● Chassis: full-steel structure completely shielded which defends electromagnetic radiation, interference, and static electricity

Function of F2100B:● Compact keyboard design and easy-to-input files.● The shape has some operations such as Proportion, Rotate, and Mirror.● The shape can be arrayed in a matrix, interaction, and stacked modes.● The steel plate can be adjusted according to any steel side.● The coordinate system can be customized to support the two-dimensional coordinates of all eight kinds.● All input and output port types and the number can be customized (normally open or normally closed).● Self-diagnostic function, to diagnose the key status and all the IO status, facilitate inspection and debug.● Provide a front USB interface for copying files.● The system can be upgraded by the USB interface easily, and we provide lifetime upgrade service.● All functions and techniques can be upgraded online and don’t worry about the after-sale service.● Import and export files by single or all files.● Parameters backup and parameter restoration.● Support the Flame, Plasma, Marker, and Demonstration four kinds of mode.● Including various types of processing parameters to meet the needs of different processes.● Flame and Plasma are separated in the control of IO ports.● Support THC(Torch Height Control), two-level preheat, three-level pierce in flame mode

Summarize:The CNC system of F2000 uses ARM and DSP motor control IC to implement cutting control, and the system is widely applied to the oxygen gas cutting and plasma cutting processing industry. The system is designed portably to be installed. The system is easy to operate and the worker can use the menu and the graphical hints to operate it. All the key buttons are designed with ergonomic considerations to be used conveniently. The front USB port can import and export files conveniently. The system interface includes many languages such as simplified Chinese, English, Russian, French, and Japanese, and can be used in many countries.

Basic Parameters/ Hardware Configuration:

Type | Data |

MCU | ARM9 |

Number of axis motion | Two axes motion interpolation (can be extended to three axes) |

Max code lines | 150,000 lines |

Single cutting code size | 4MB |

File memory space | Electronic bulk memory chip, 512MB |

User file memory space | 256MB |

Controlling accuracy | ±0.001mm (millimeter) |

Coordinate range | ± 99999.99mm |

Max pulse frequency | 250KHz;Max motion speed:25m/sec. |

System power | DC +24V |

ime resolving capability | 10ms |

System working condition | Temperature:0℃ - +55℃; Relative Humidity: 0-95%. |

Interface | USB |

Frame | Overall metal structure, electromagnetic radiation resistant, anti interference, anti-static |

Special configuration | Touchpad, 100m wireless remote controller, and wire control box(optional for a full range of F2000 series) |

Keyboard | PCB film keyboard, PS/2 interface, OMRON button |

Characteristics of System

- 45 categories of different graphics (including grid pattern), chip part and hole part are alternatives.

- Graphics have some operations such as Proportion, Rotate, Mirror.

- Graphics can be arrayed in matrix, interaction, stacked modes

- According to plate thickness, the cutting speed is automatically restricted by a speed limit in the corner, effectively preventing over-burning.

- metric system/ imperial system switch

- Steel plates can be adjusted according to any steel side.

- Coordinate system can be customized to support the two-dimensional coordinates of all eight kinds.

- All input and output port type and the number can be customized (normally open or normally closed)

- system and parameters backup, update system online

- Chinese / English (including Japanese, Russian, French and other languages )file system and menu can be switched only by one key.

- select row and column manually.

- support edge cutting and offset cutting.

- Automatically memorize the working situation and the last cutting point when power off.

- Dynamic/static illustration of the process, graphics zoom in / out, dynamically tracking cut-off point under zooming state.

- support artgrave, TYPE III, PM2000 cam software

- set up different administration authority to and the corresponding password to safeguard the interests of managers.

Last update: 2024