CNC machine parts

HMI & PLC

Electrical devices

Posts

Plasma controller

type

status

date

slug

summary

tags

category

icon

password

📙Model & price

1.Plasma controller

2.THC controller

📙Product description

📄Fangling plasma controller

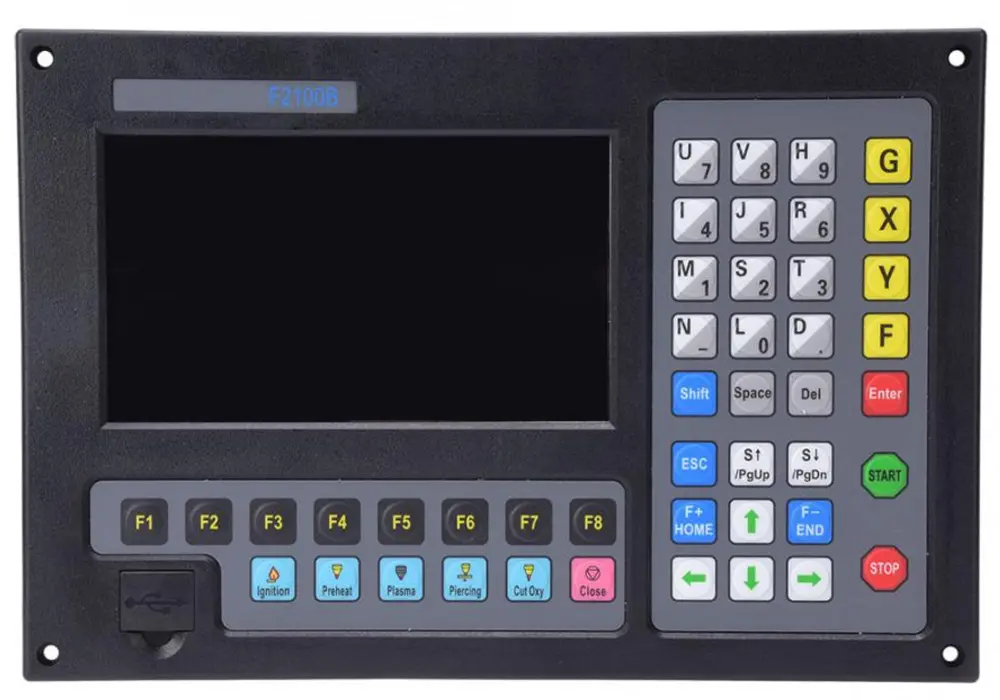

[1]F2100B

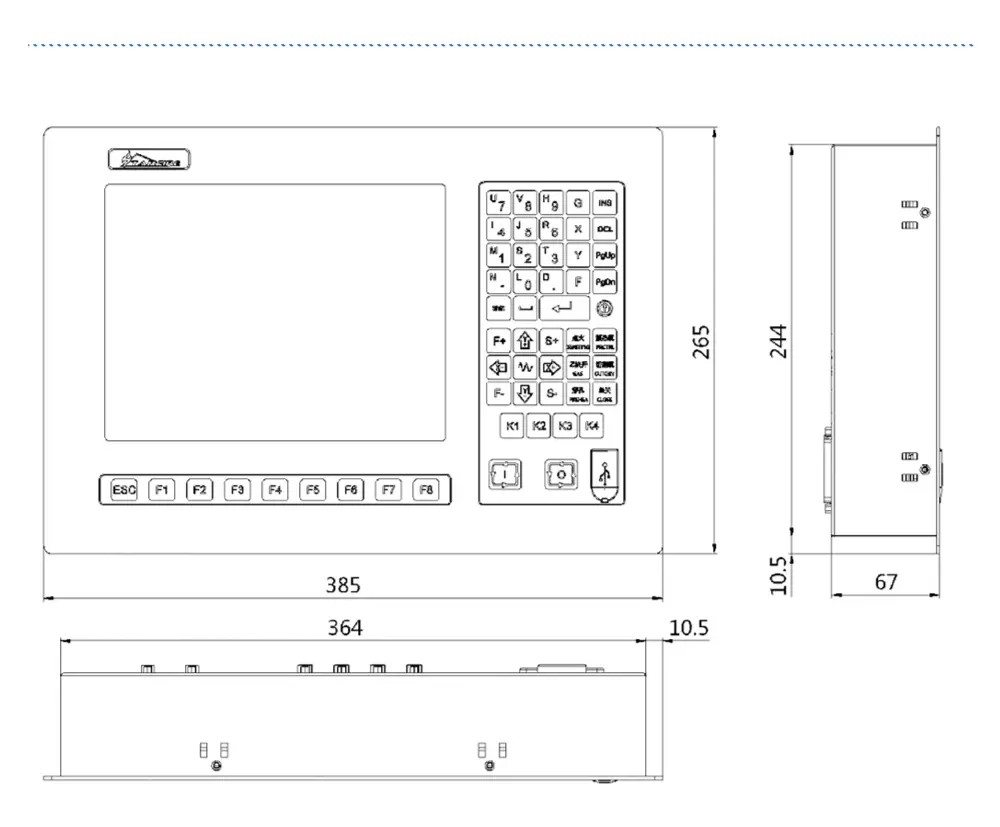

Technical indicator● Control Axis: 2-axis linkage● Control accuracy: +/-0.001mm● Coordinate range: +/- 99999.99mm● Max pulses: 200 kHz.● Max speed: 15,000 mm/m● Max lines of code: 80,000lines● Max size of single code file: 4M● Time resolution: 10ms● Working Voltage: DC +24V direct-current power input, power > 80W。● Working Temperature: -10℃~+60℃. Relative Humidity, 0~95%.● Max power of drive arc THC motor: 45W (suitable for models with “T”). If you need more power, you can select a maximum value: 200W.

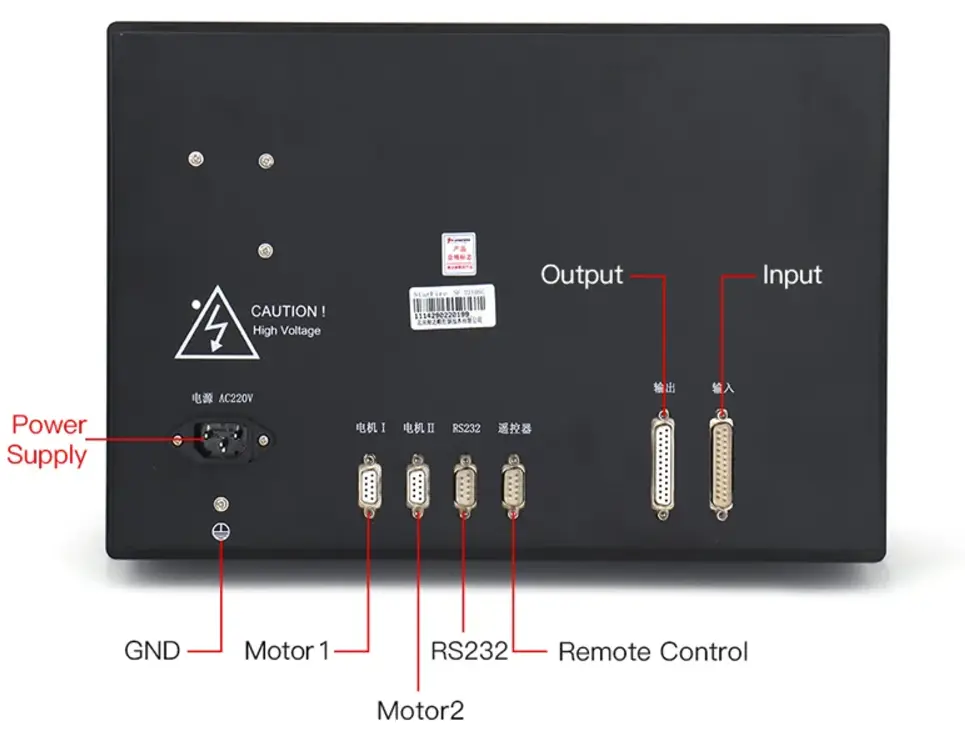

Controller Interface● DB15 pins SMA Male interface of 2 axes of the motor drive.● DB25 pins SMA Female interface of 16 channels optoelectronic isolation output ports max backflow current 300mA.● DB25 pins SMA Male interface of 16 channels optoelectronic isolation input ports, max output current 300mA.● USB interface on the front panel, for the convenience of transmitting cutting code.● Extend IO input/output ports, PWM input ports, and analog input ports.● Optional standard DB9 core male serial port RS232 interface.

Hardware Configuration● Monitor:7 inch, 800*480, high definition 16 million colors, and high brightness LCD● Memory: 64M SDRAM● Program space available for user: 256M electronic hard disk● CPU frequency: 400MHz● USB: USB 1.1 front interface, at least 16GB U disk supportable● Keyboard: PCB keyboard● Chassis: full-steel structure completely shielded which defends electromagnetic radiation, interference, and static electricity

Function of F2100B:● Compact keyboard design and easy-to-input files.● The shape has some operations such as Proportion, Rotate, and Mirror.● The shape can be arrayed in a matrix, interaction, and stacked modes.● The steel plate can be adjusted according to any steel side.● The coordinate system can be customized to support the two-dimensional coordinates of all eight kinds.● All input and output port types and the number can be customized (normally open or normally closed).● Self-diagnostic function, to diagnose the key status and all the IO status, facilitate inspection and debug.● Provide a front USB interface for copying files.● The system can be upgraded by the USB interface easily, and we provide lifetime upgrade service.● All functions and techniques can be upgraded online and don’t worry about the after-sale service.● Import and export files by single or all files.● Parameters backup and parameter restoration.● Support the Flame, Plasma, Marker, and Demonstration four kinds of mode.● Including various types of processing parameters to meet the needs of different processes.● Flame and Plasma are separated in the control of IO ports.● Support THC(Torch Height Control), two-level preheat, three-level pierce in flame mode

Summarize:The CNC system of F2000 uses ARM and DSP motor control IC to implement cutting control, and the system is widely applied to the oxygen gas cutting and plasma cutting processing industry. The system is designed portably to be installed. The system is easy to operate and the worker can use the menu and the graphical hints to operate it. All the key buttons are designed with ergonomic considerations to be used conveniently. The front USB port can import and export files conveniently. The system interface includes many languages such as simplified Chinese, English, Russian, French, and Japanese, and can be used in many countries.

Basic Parameters/ Hardware Configuration:

Type | Data |

MCU | ARM9 |

Number of axis motion | Two axes motion interpolation (can be extended to three axes) |

Max code lines | 150,000 lines |

Single cutting code size | 4MB |

File memory space | Electronic bulk memory chip, 512MB |

User file memory space | 256MB |

Controlling accuracy | ±0.001mm (millimeter) |

Coordinate range | ± 99999.99mm |

Max pulse frequency | 250KHz;Max motion speed:25m/sec. |

System power | DC +24V |

ime resolving capability | 10ms |

System working condition | Temperature:0℃ - +55℃; Relative Humidity: 0-95%. |

Interface | USB |

Frame | Overall metal structure, electromagnetic radiation resistant, anti interference, anti-static |

Special configuration | Touchpad, 100m wireless remote controller, and wire control box(optional for a full range of F2000 series) |

Keyboard | PCB film keyboard, PS/2 interface, OMRON button |

Characteristics of System

- 45 categories of different graphics (including grid pattern), chip part and hole part are alternatives.

- Graphics have some operations such as Proportion, Rotate, Mirror.

- Graphics can be arrayed in matrix, interaction, stacked modes

- According to plate thickness, the cutting speed is automatically restricted by a speed limit in the corner, effectively preventing over-burning.

- metric system/ imperial system switch

- Steel plates can be adjusted according to any steel side.

- Coordinate system can be customized to support the two-dimensional coordinates of all eight kinds.

- All input and output port type and the number can be customized (normally open or normally closed)

- system and parameters backup, update system online

- Chinese / English (including Japanese, Russian, French and other languages )file system and menu can be switched only by one key.

- select row and column manually.

- support edge cutting and offset cutting.

- Automatically memorize the working situation and the last cutting point when power off.

- Dynamic/static illustration of the process, graphics zoom in / out, dynamically tracking cut-off point under zooming state.

- support artgrave, TYPE III, PM2000 cam software

- set up different administration authority to and the corresponding password to safeguard the interests of managers.

[2]F2100T

Type | Data |

Control Axis | 2 Axis Linkage (3 Axis Customizable) |

Operating System | High-performance ARM |

Control Accuracy | +/-0.001mm |

Max Pulses | 200 kHz |

Max Speed | 15,000 mm/m |

Space | 256M |

Working Voltage | DC +24V |

Support | Plasma Cutting, Flame Cutting, Powder Marking, Demo |

Shanghai Fangling F2100T CNC controller is a new product, absorbing the advantages of many CNC controllers, which is more user-friendly, more convenient and more cost-effective. The controller can control the motion of two axes, which is apt to the application of flame, plasma or laser cutting. This series is suitable for all 2 axis CNC machines which support position control mode. The controller is a high performance ARM chip and ultra large scale programmable device FPGA, runs a multi task real-time operating system and adopts the method of combining software interpolation with hardware interpolation, making high-speed operation more stable and reliable. The Reflected speed is very fast. Based on Fangling's research of CNC systems for many years, the machine's control is more stable and the protection mechanism is quite good.

F2100T-Integrated THC

- Integrated Torch Height Control function.

- External voltage divider with good anti-interference ability.

- Option operating panel for voltage adjustment(Mark your model).

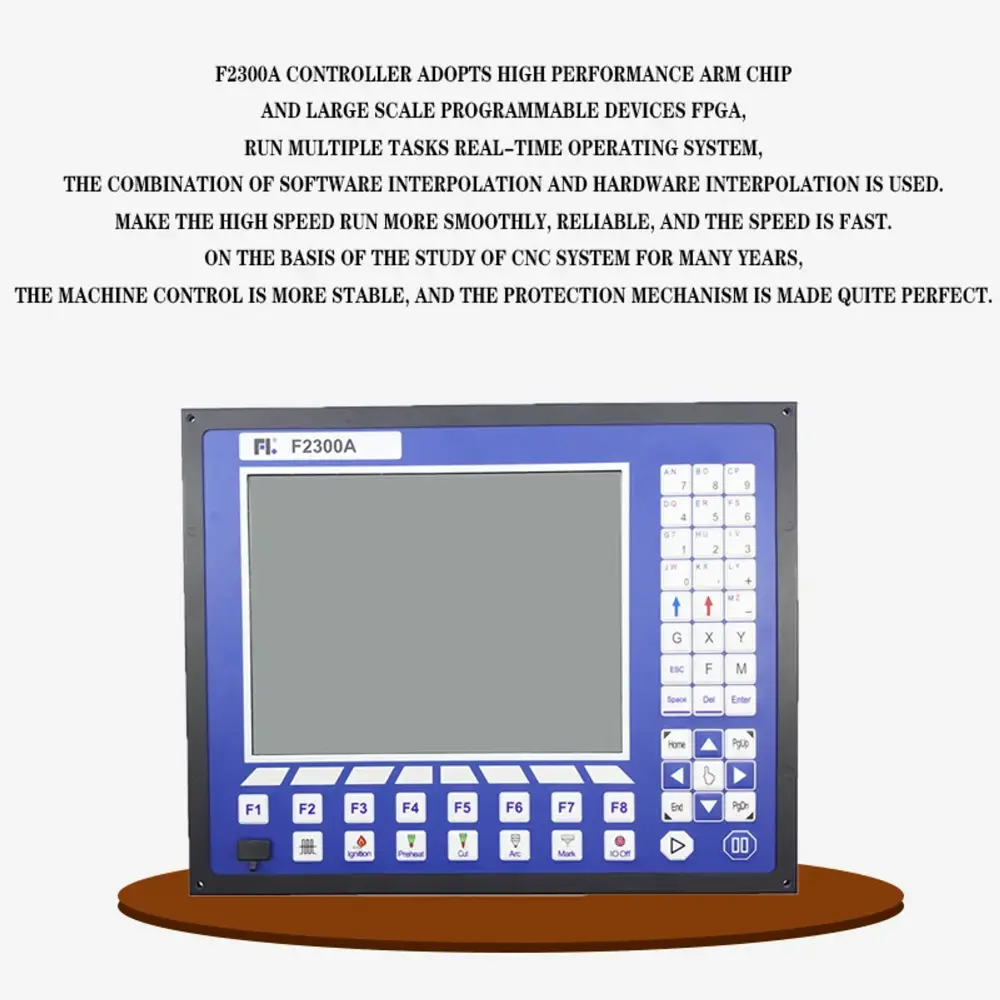

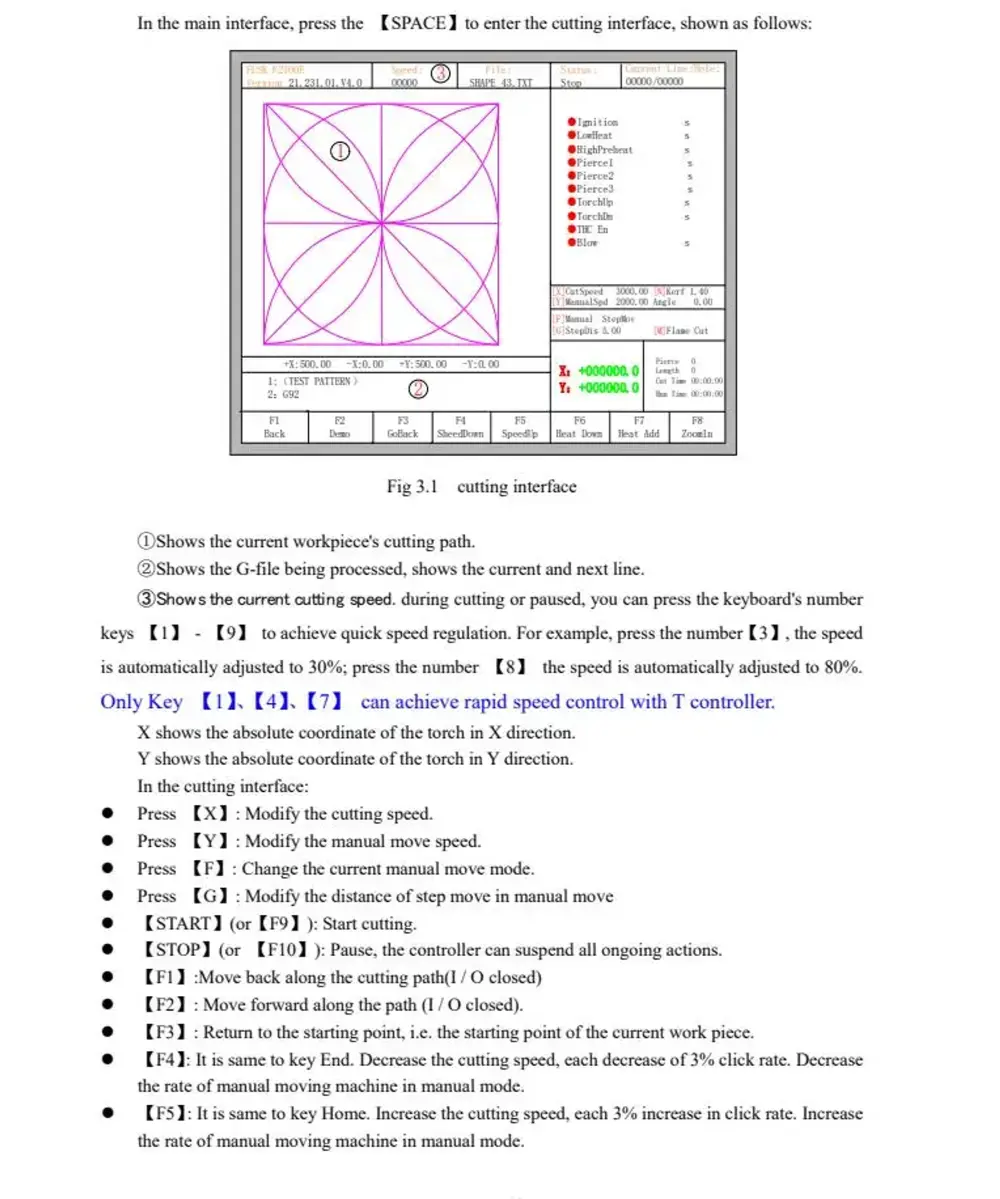

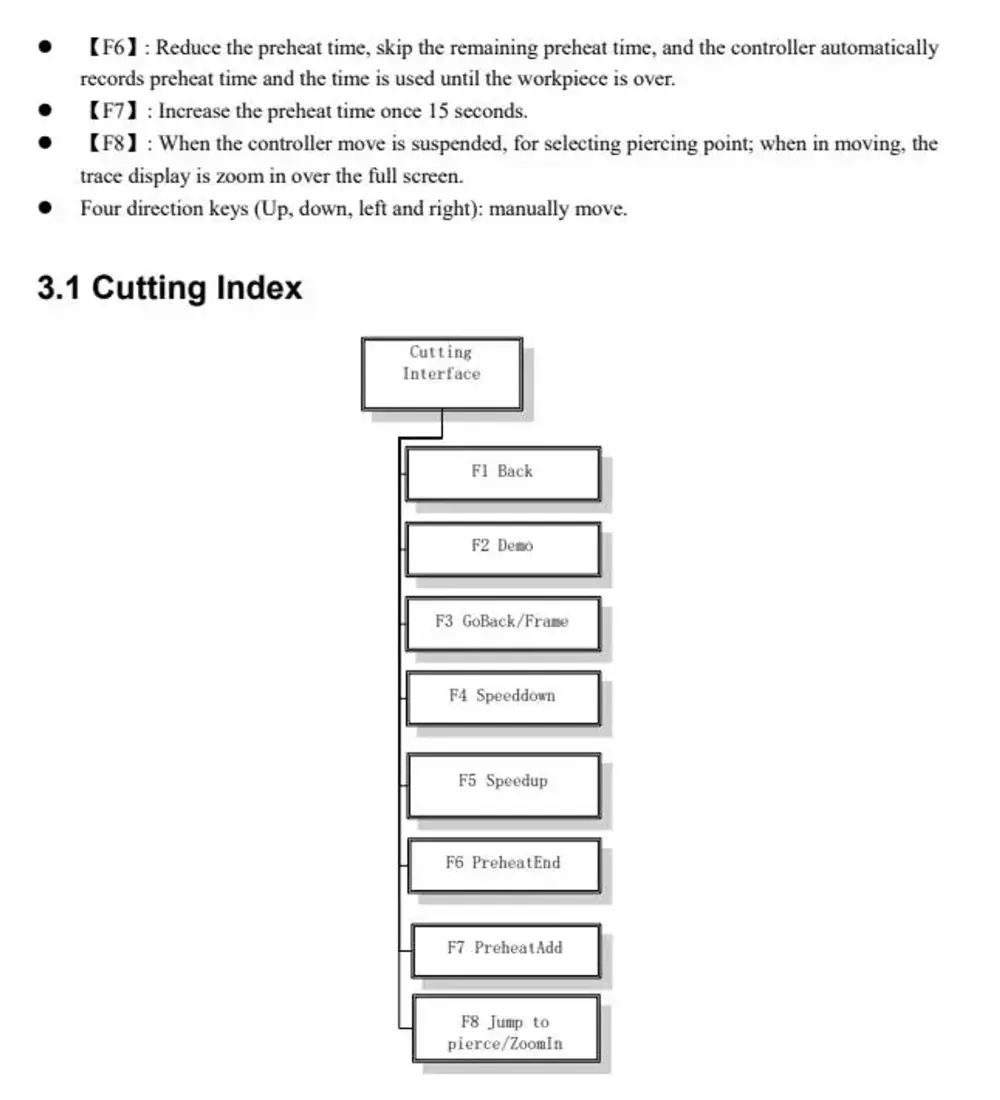

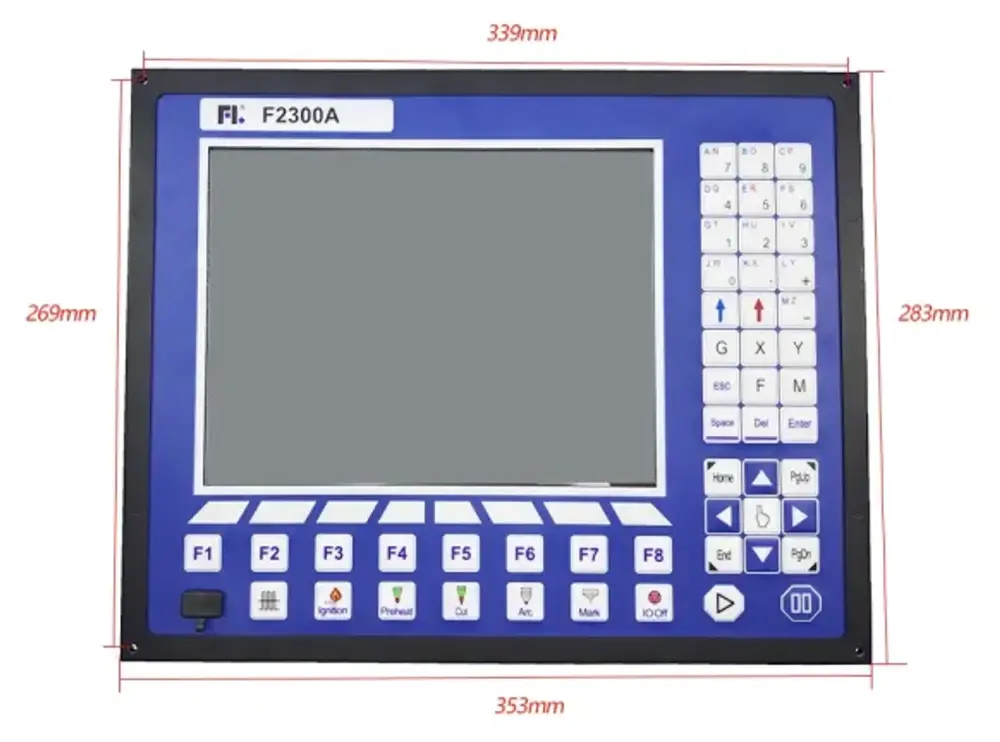

[3]F2300A

Type | Data |

Control Axis | 2 Axis Linkage (3 Axis Customizable) |

Operating System | High-performance ARM |

Control Accuracy | +/-0.001mm |

Max Pulses | 200 kHz |

Max Speed | 15,000 mm/m |

Space | 256M |

Working Voltage | DC +24V |

Support | Plasma Cutting, Flame Cutting, Powder Marking, Demo |

AdvantagesShanghai Fangling F2300A CNCcontroller is a new product, absorbing the advantages of many CNC controllers,which is more user-friendly, more convenient and more cost-effective. The controller can control the motion of two axes, which is apt to the application of flame, plasma or laser cutting.The controller is a high performance ARM chip and ultra large scale programmable device FPGA, runs a multi task real-time operating system and adopts the method of combining software interpolation with hardware interpolation, making high-speed operation more stable and reliable. The Reflected speed is very fast.

Technical index:

- Number of control axes: 2-axis linkage (three-axis or four-axis can be customized)

- Control accuracy: ±0.001mm

- Coordinate range: ± 99999.99mm

- Maximum pulse frequency: 200KHz; Maximum operating speed: 15 m/min

- Maximum number of program lines: 80,000 lines

- Maximum single program: 4M

- Time resolution: 10ms

- System working power: DC +24V DC power input, power is greater than 80W.

- System working environment: temperature -10℃ to +60℃; relative humidity 0-95% non-condensing

- The maximum power of the drive arc voltage height-adjusting motor: 45W (Note: only with T system). If you need more power, you can choose up to 200W.

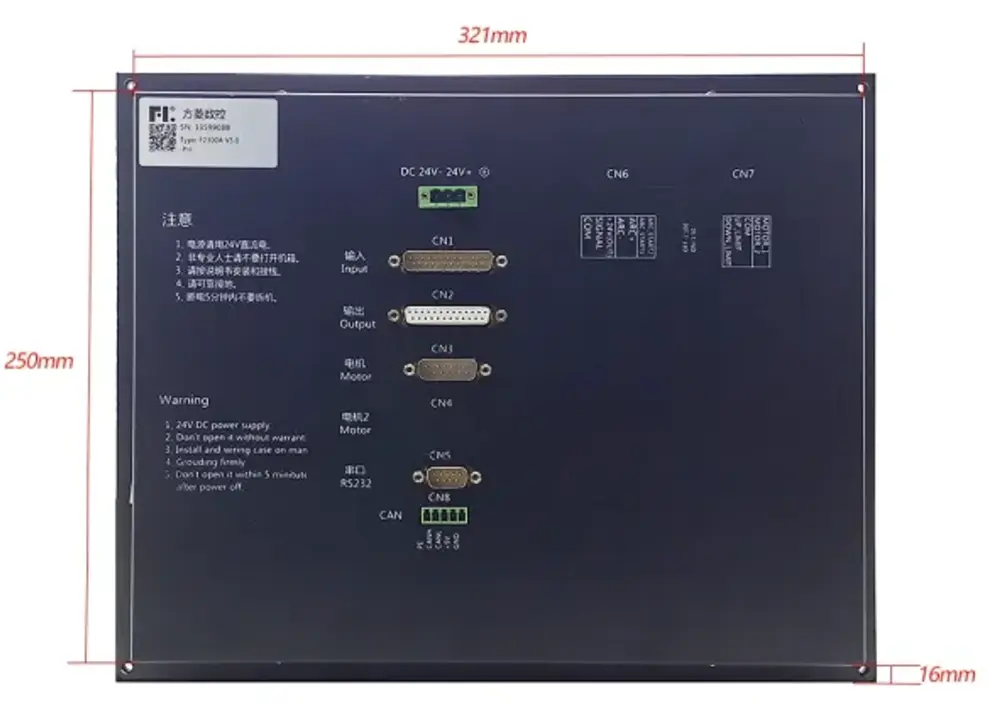

System interface:

- DB15 core male two-axis motor drive interface

- DB25 core female connector 16-channel photoelectric isolation output, the maximum reverse current is 300mA

- DB25 core male connector 16-channel photoelectric isolation input, the maximum input current is 300mA

- The front panel has a built-in USB interface, which is convenient for users to transfer cutting codes

- Expansion IO input and output port; PWM input port; analog input port

- Optional standard DB9 core male serial port RS232 interface

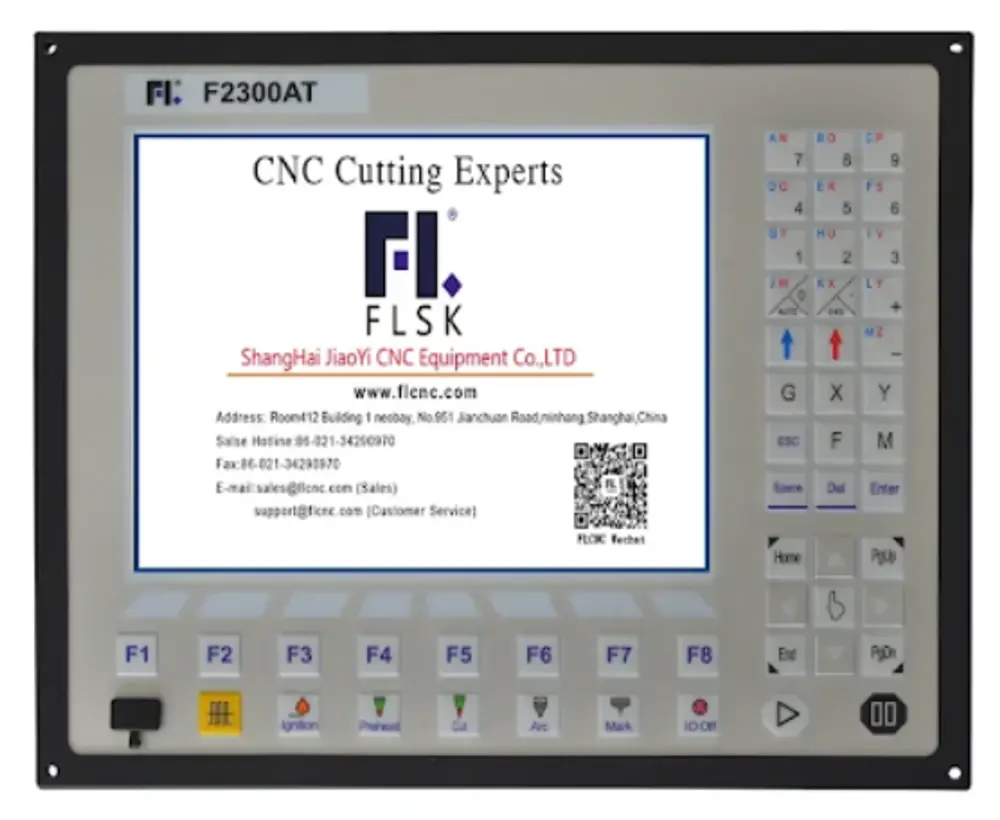

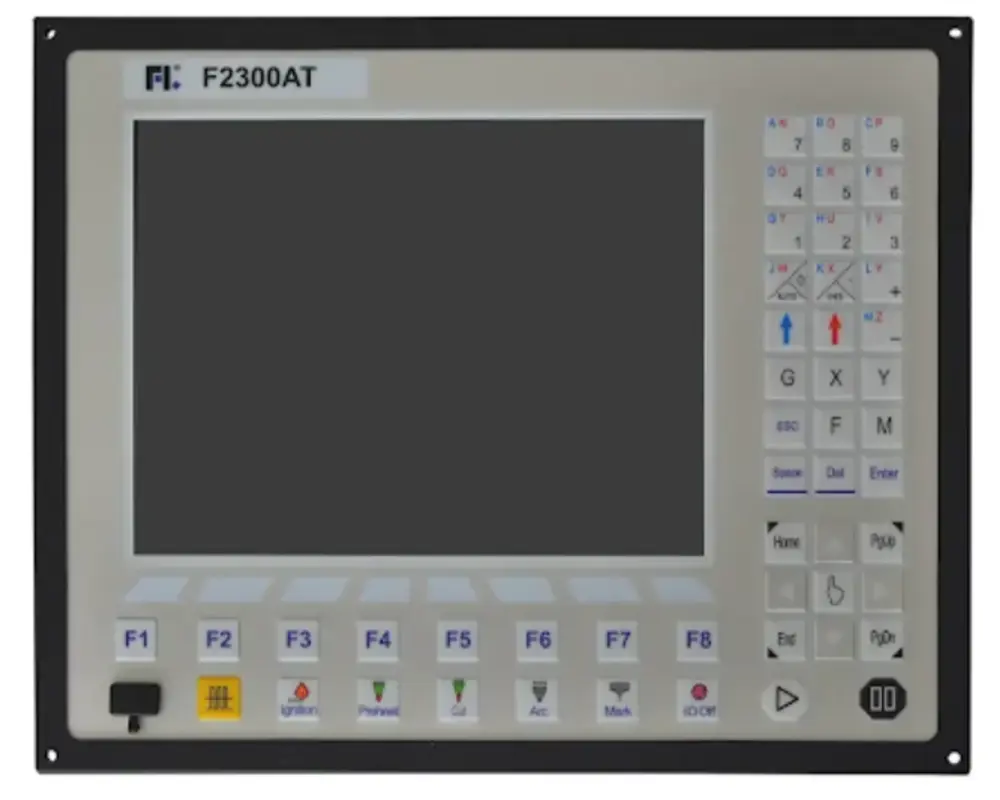

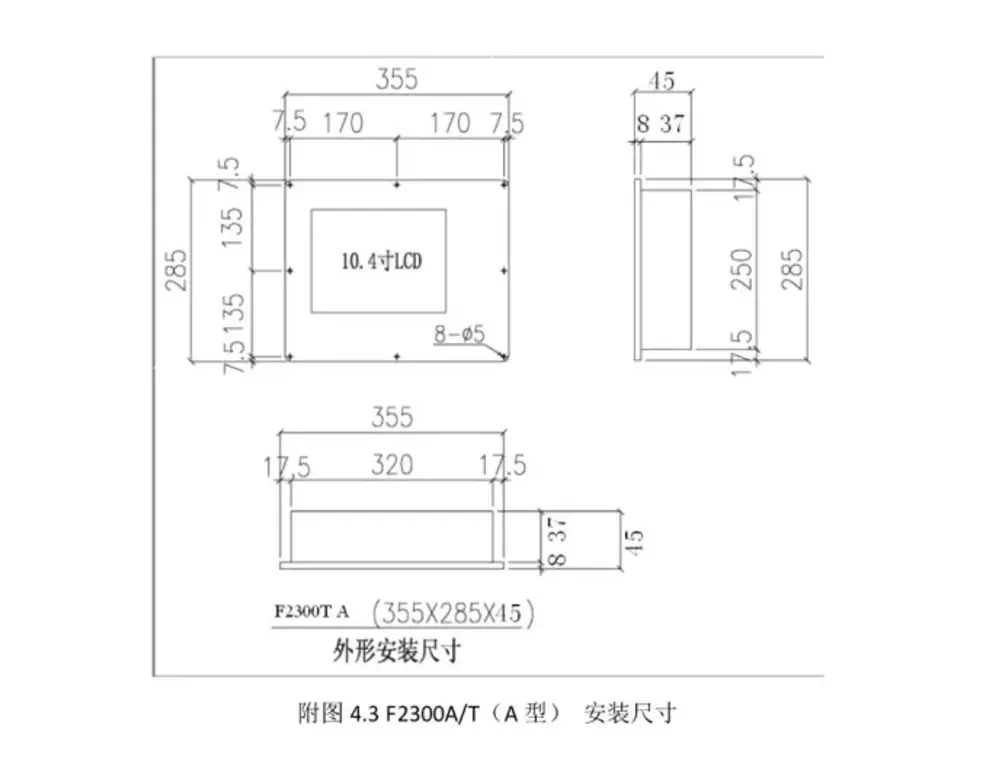

[4]F2300AT

Details:The F2300AT CNC controller is a new product, absorbing the advantages of many CNC controllers,which is more user-friendly, more convenient and more cost-effective. The controller can control the motion of two axes, which is apt to the application of flame, plasma or laser cutting. This series is suitable for all two axis CNC machines which support position control mode.The controller is a high performance ARM chip and ultra large scale programmable device FPGA, runs a multi task real-time operating system and adopts the method of combining software interpolation with hardware interpolation, making high-speed operation more stable and reliable. The Reflected speed is very fast. Based on Fangling's research of CNC systems for many years, the machine's control is more stable and the protection mechanism is quite good.

Characteristics:

- Chinese/English/French/Portuguese/Russian/Denmark/Korean language are supported, the language can be switched easily. In addition to Chinese and English, it needs customers to provide language translation documents. In addition to Arabic, other languages are all available.

- System can be upgraded by USB. Lifetime Software upgrade service.

- Support CAN bus connection.

- Cutting technique parameters library.

- Support Multi-stations(Multiple THC and its panel) configuration.

- Support Laser pointing function.

- Support Plasma cutting dynamic perforation function.

- Process workpieces, Running time and perforation times statistics.

- Support Edge cutting, lesser preheat time for thick plate.

- Corner limit speed depends on the thickness of the plate, preventing overburn.

- The view for cutting shape, zoom in/out, easy to track the cutting cursor.

- Blackout, breakpoint memory function.

- “Offset cutting”function can prevent the waste of the workpiece when miscalculation happens.

- Can set different levels of administration, password setting can protect your rights.

CAN bus

- All devices are connected by CAN bus.

- Convenient and more stable connection.

- More stable signal transfer.

- Double wire serial bus communication.

- Better anti-interference ability.

- Specifications:

Type | Data |

Control Axis | 2 axis linkage(3 axis customizable) |

Operating System | High-performance ARM |

Control accuracy | +/-0.001mm |

Max pulses | 200 kHz |

Max speed | 15,000 mm/m |

Space | 256M |

Working Voltage | DC +24V |

Support | Plasma cutting, Flame cutting, Powder Marking, Demo |

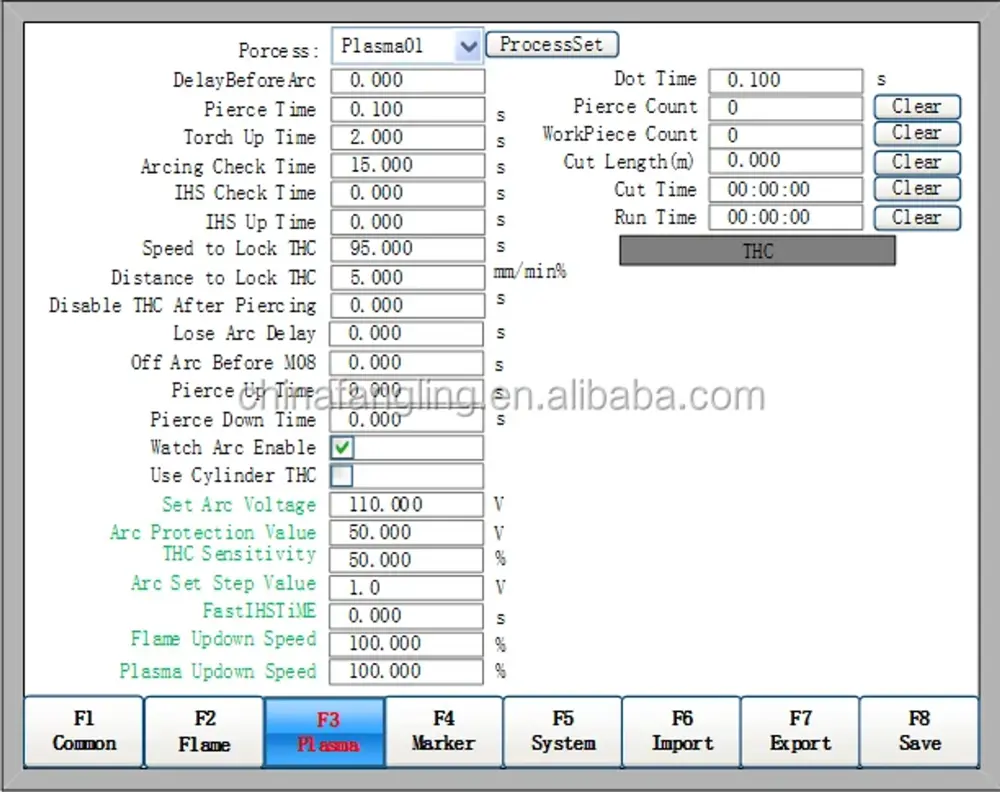

[5]F2300B

Type | Data |

Control Axis | 2 Axis Linkage (3 Axis Customizable) |

Operating System | High-performance ARM |

Control Accuracy | +/-0.001mm |

Max Pulses | 200 kHz |

Max Speed | 15,000 mm/m |

Space | 256M |

Working Voltage | DC +24V |

Support | Plasma Cutting, Flame Cutting, Powder Marking, Demo |

AdvantagesThe Fangling F2300B CNC controller is a new product, absorbing the advantages of many CNC controllers,which is more user-friendly, more convenient and more cost-effective. The controller can control the motion of two axes, which is apt to the application of flame, plasma or laser cutting. This series is suitable for all two axis CNC machines which support position control mode.The controller is a high performance ARM chip and ultra large scale programmable device FPGA, runs a multi task real-time operating system and adopts the method of combining software interpolation with hardware interpolation, making high-speed operation more stable and reliable. The Reflected speed is very fast. Based on Fangling's research of CNC systems for many years, the machine's control is more stable and the protection mechanism is quite good.

CAN Bus

- All devices are connected by CAN bus.

- More convenient and stable connection.

- More stable signal transfer.

- Double wire serial bus communication.

- Better anti-interference ability.

Parameters Library

- Users can directly import the presave cutting parameters.

- Automatically synchronize THC parameters.

- No more repeat settings.

- Improve the working efficiency.

[6]F2300BX

Details:F2300BX CNC controller is a new product, absorbing the advantages of many CNC controllers,which is more user-friendly, more convenient and more cost-effective. The controller can control the motion of two axes, which is apt to the application of flame, plasma or laser cutting. This series is suitable for all two axis CNC machines which support position control mode.The controller is a high performance ARM chip and ultra large scale programmable device FPGA, runs a multi task real-time operating system and adopts the method of combining software interpolation with hardware interpolation, making high-speed operation more stable and reliable. The Reflected speed is very fast. Based on Fangling's research of CNC systems for many years, the machine's control is more stable and the protection mechanism is quite good.

Characteristics:

- Chinese/English/French/Portuguese/Russian/Denmark/Korean language are supported, the language can be switched easily. In addition to Chinese and English, it needs customers to provide language translation documents. In addition to Arabic, other languages are all available.

- System can be upgraded by USB. Lifetime Software upgrade service.

- Support CAN bus connection.

- Cutting technique parameters library.

- Support Multi-stations(Multiple THC and its panel) configuration.

- Support Laser pointing function.

- Support Plasma cutting dynamic perforation function.

- Process workpieces, Running time and perforation times statistics.

- Support Edge cutting, lesser preheat time for thick plate.

- Corner limit speed depends on the thickness of the plate, prevent overburn.

- The view for cutting shape, zoom in/out, easy to track the cutting cursor.

- Blackout, breakpoint memory function.

- “Offset cutting”function can prevent the waste of the workpiece when miscalculation happens.

- 14.Can set different levels of administration, password setting can protect your rights.

CAN bus

- All devices are connected by CAN bus.

- Convenient and more stable connection.

- More stable signal transfer.

- Double wire serial bus communication.

- Better anti-interference ability.

Type | Data |

Control Axis | 2 axis linkage(3 axis customizable) |

Operating System | High-performance ARM |

Control accuracy | +/-0.001mm |

Max pulses | 200 kHz |

Max speed | 15,000 mm/m |

Space | 256M |

Working Voltage | DC +24V |

Support | Plasma cutting, Flame cutting, Powder Marking, Demo |

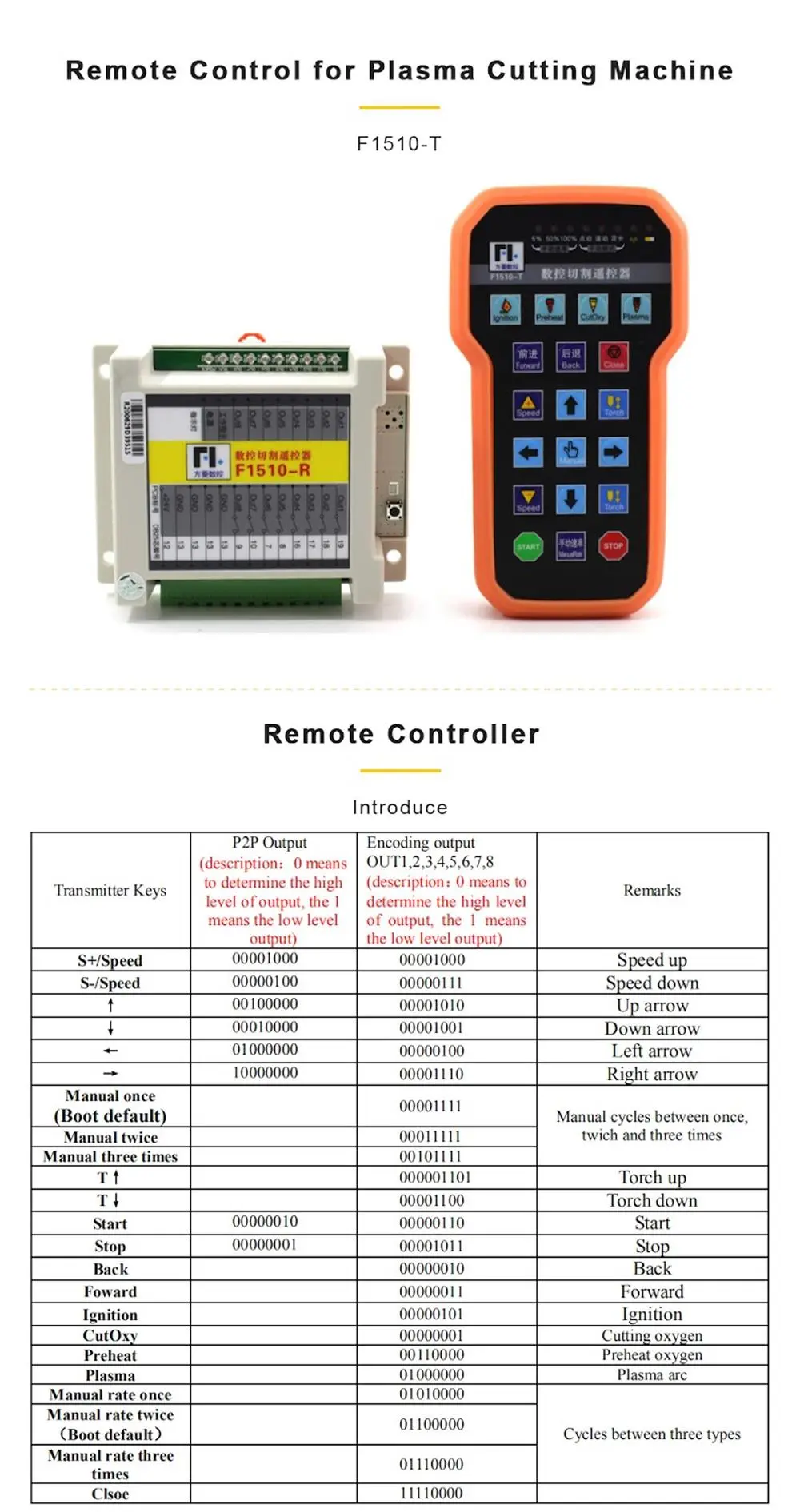

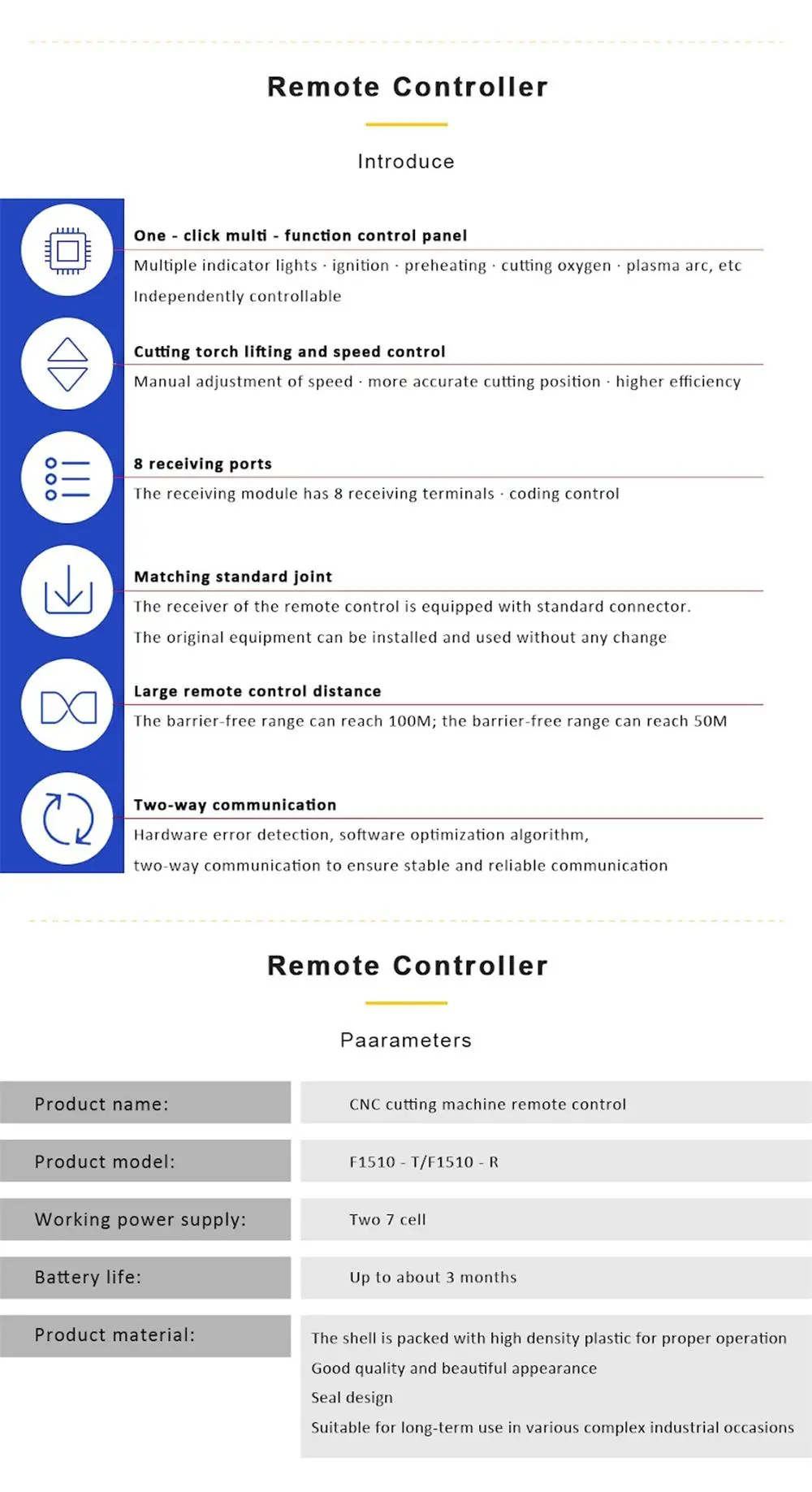

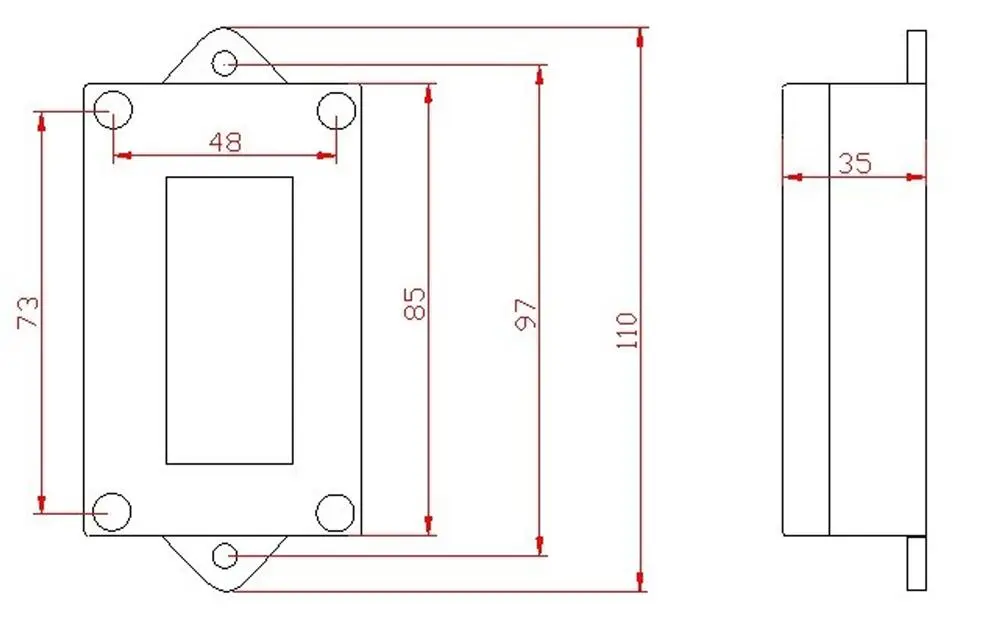

[7]F1510 remote

F1510 is used for version V4 and below, and F1521 is used for version V5.

Please confirm the version of your controller before purchasing.

Specification:

- 433MHz free ISM frequency channel, free license on trial

- Remote controlling distance > 30m, at least not below 0.5m

- Hardware test error code, software optimizing algorithm, bi-direction communication, ensure the communication stable and reliable

- Send module matches to address with receive the module, the address can be set manually, at most 128 supportable addresses

- Wireless remote controlling send module is supplied power by a dry battery, at least working more than 6 months service time The receiver module is set into 8421 port mode or P2P mode, at most 16 output ports

Interpretation of Jumper Switch

- Address segment

- The first seven bits of the jumper switch (No.1 -7) are address codes; the status of

- These seven bits requires that the sender and receiver must be the same. If they are different,the receiver cannot reply.

- Note: If the sender is, there is also an 8-bit jumper switch inside. Therefore at the same time, 128 pairs of sender and receiver can simultaneously work at most.

- Function select segment

- The first bit of a jumper switch is the function select segment. When it is set to short circuit, select 8421 code to receive mode. When it isn’t set to short circuit, select independent IO port(P2P) receive mode.

Packing List:1pcs F1510 remote1pcs wireless receiver

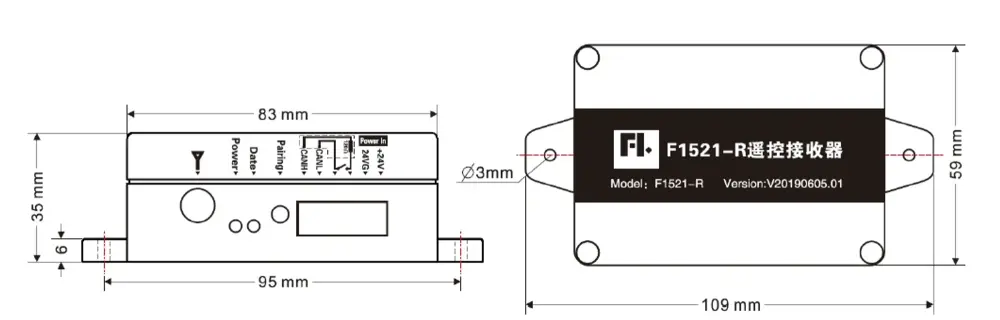

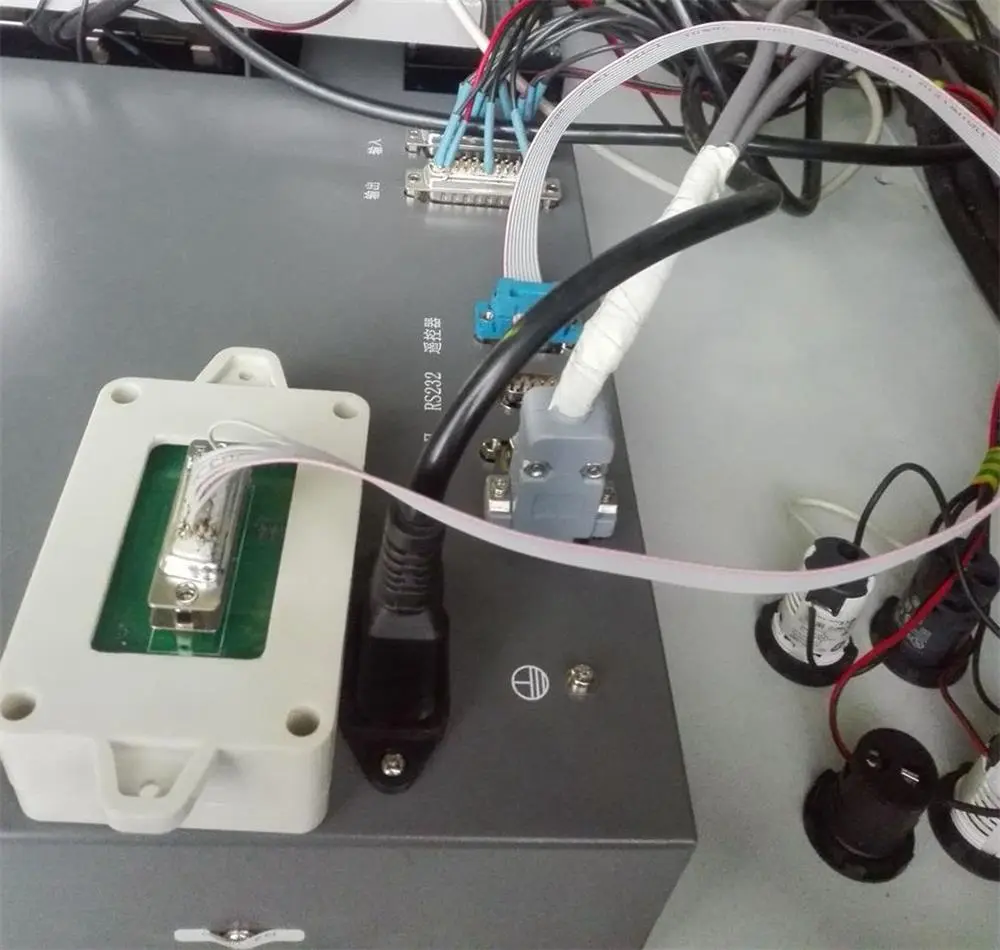

[8]F1521 remote

F1510 is used for version V4 and below, and F1521 is used for version V5.

Note:

- The remote control receiver can withstand the instantaneous voltage up to 36V;

- The input voltage requires Fangyi to provide a constant voltage. If the voltage fluctuation is too large (the instantaneous voltage is greater than 36V), it will cause the actual voltage to be too high and burn the fuse or other original devices inside the transmitter.

Specification:

- 433MHz free ISM band free of license trial;

- The remote control distance is more than 200m, at least not less than 0.5m;

- Hardware error detection, software optimization algorithm, two-way communication to ensure stable and reliable communication;

- The wireless remote control transmission module is powered by dry battery, which can be used for at least 6 months;

- The receiving module f1521 is connected by CAN bus, which is convenient for users to connect.

- It is upgraded from F1510, and The accuracy is higher and the signal is better.

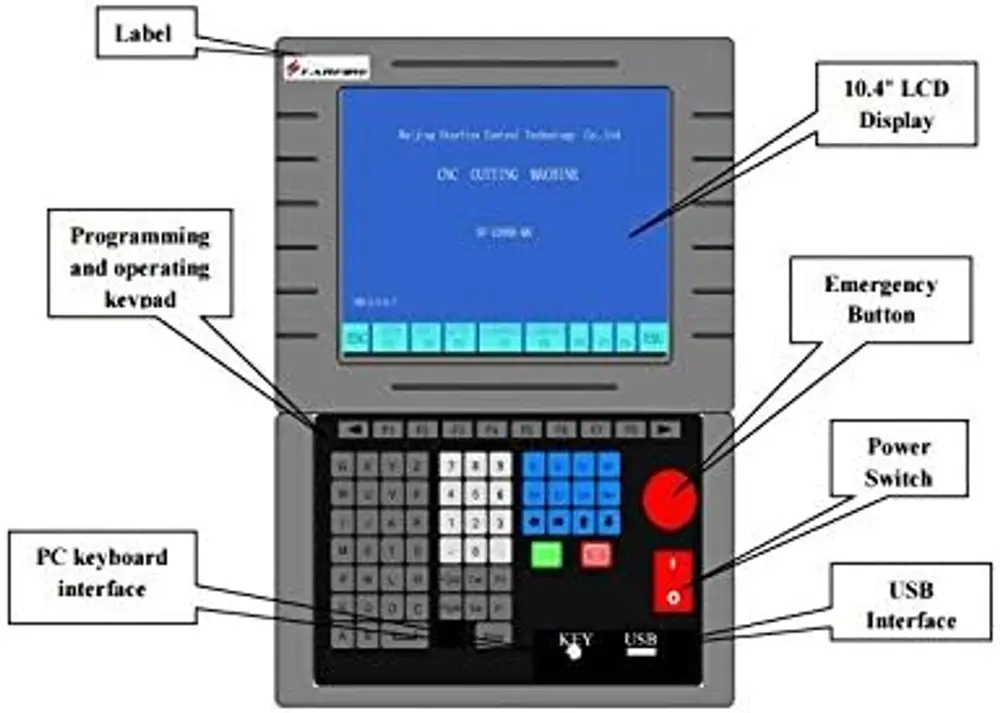

📄Starfire plasma controller

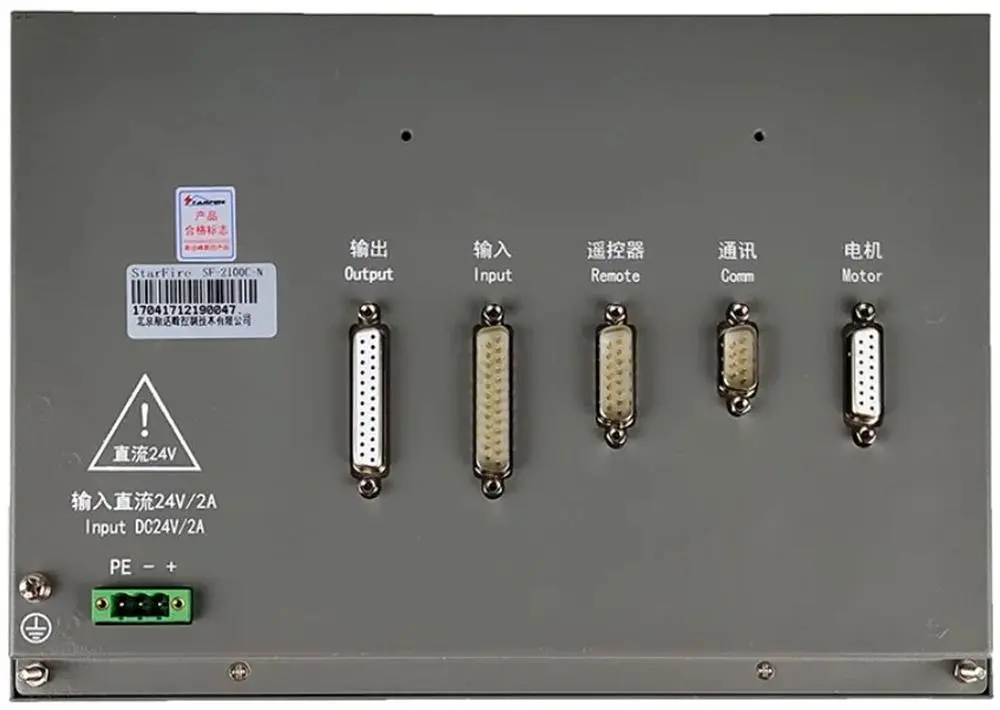

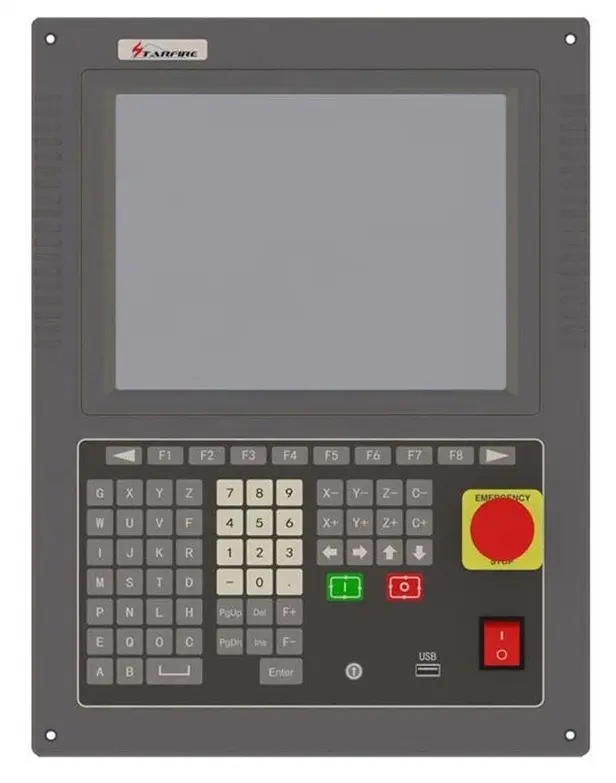

[1]SF-2100C

Features:

- SF-2100C cutting machine CNC controller is suitable for all kinds of flame, plasma, high-pressure water jet, laser cutting machines. It is widely used in industries such as metal processing, advertising and stone.

- The system has a highly reliable design and has the ability to resist plasma interference, lightning strike and surge. Practical flame/plasma cutting process, automatic corner speed control during plasma processing, and height regulator control. Remote operation is possible with a wireless remote control.

- It has the function of cutting compensation, and detects whether the compensation in the program is reasonable, and makes corresponding reports for users to choose;

- Break-point recovery: automatic power-off recovery function and break-point automatic memory;

- Arbitrary selection and perforation point processing function;

- It has the epitaxial perforation function suitable for thick plates, and the bridging function suitable for thin plates;

- During rollback, selection, break-point recovery, you can choose the perforation position and other functions, which is very convenient for the user's control. Cutting can be transferred at any time;

- Using a special small line segment processing function, it runs smoothly. It can be widely used in metal cutting, advertising, iron art, etc.;

- Parts library with 24 kinds of graphics (expandable), including commonly used basic machining parts;

- Fully compatible with StarCAM nesting software, and compatible with mainstream nesting software such as for IBE (Germany) and FASTCAM;

- Multi-language operation interface conversion, dynamic graphic display, 1~8 times of graphic enlargement, automatic tracking of moving points. The U disk can be used for reading programs and timely software upgrades.

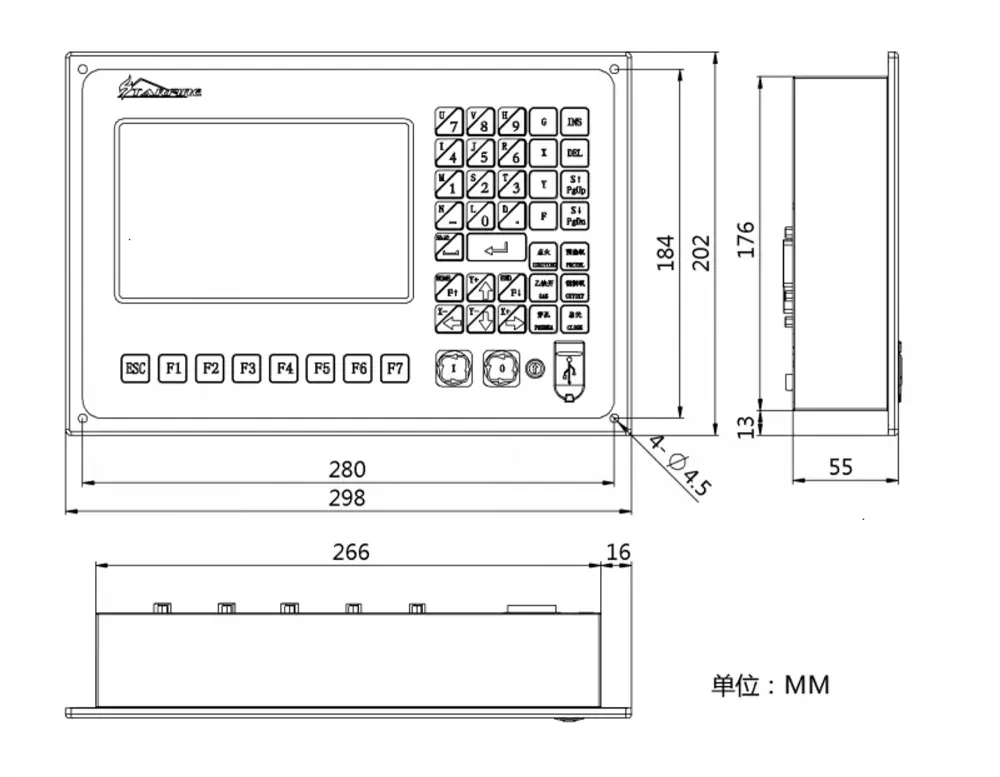

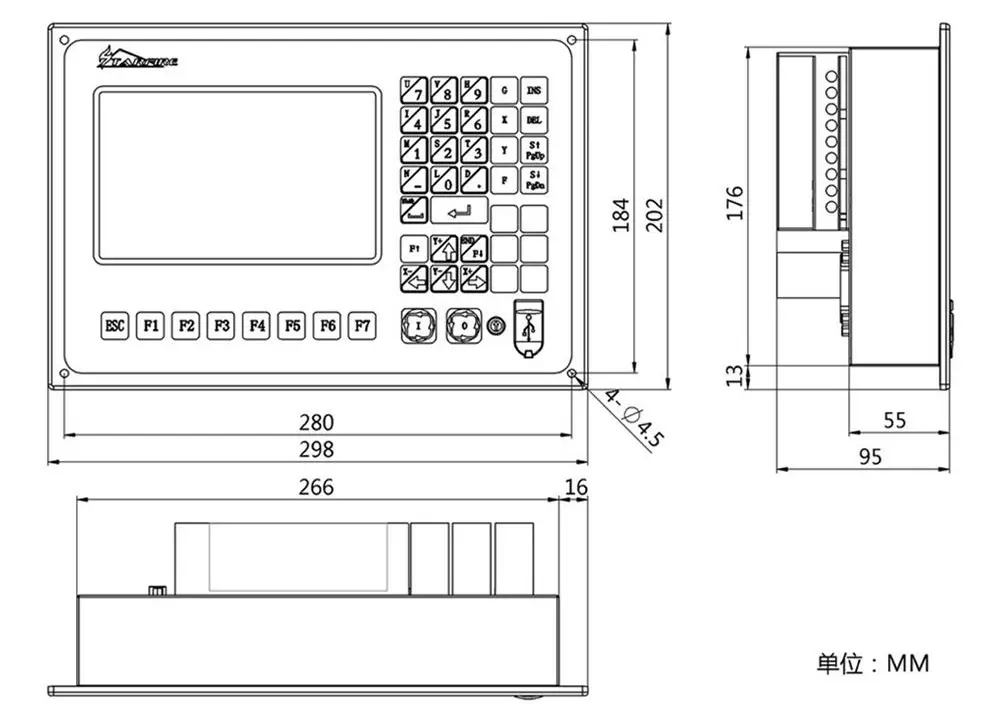

Specifications:

- Processor: using industrial-grade processing chip for ARM;

- Display: 7" 800*480 color LCD display;

- Input and output: the system provides 16 photoelectric isolation inputs and 16 photoelectric isolation outputs;

- Number of linkage axes: 2 axes, which can be expanded to 3 linkage axes;

- Maximum speed: not less than 24 m/min;

- Pulse equivalent: flexible adjustment;

- Storage space: 4G large user program storage capacity and processing program is not limited;

- Chassis size: 298 x 202 x 65mm/11.7 x 8 x 2.6";

- Working temperature: 0°C to +40°C; Storage temperature: -20°C to +60°C.

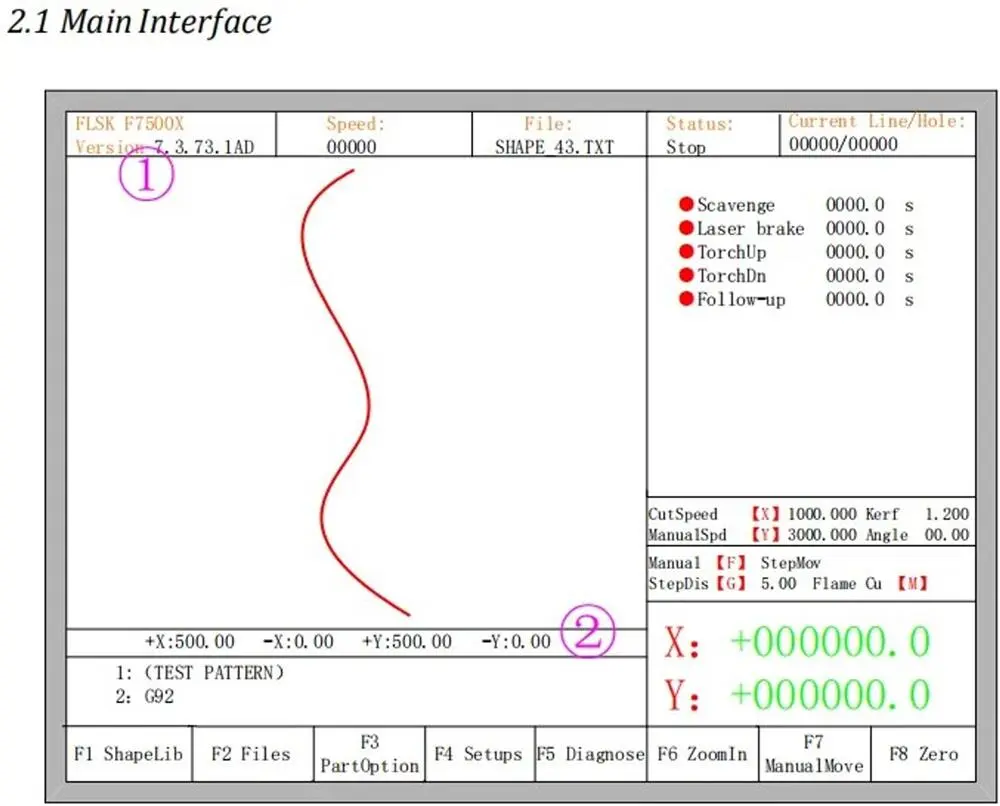

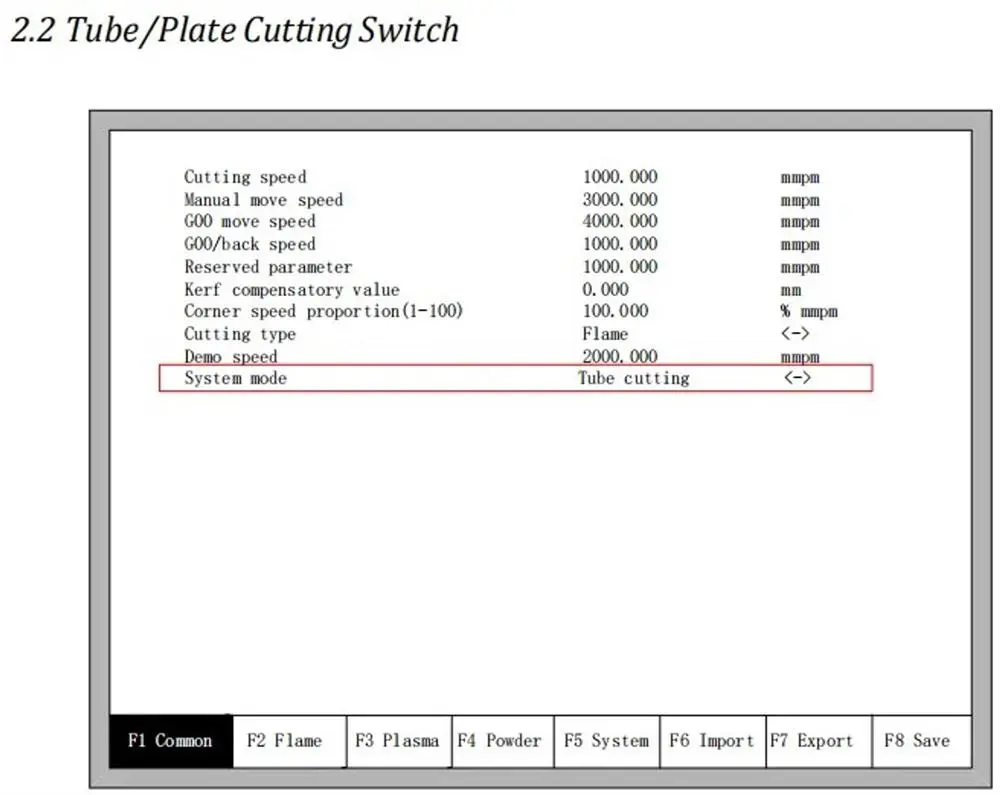

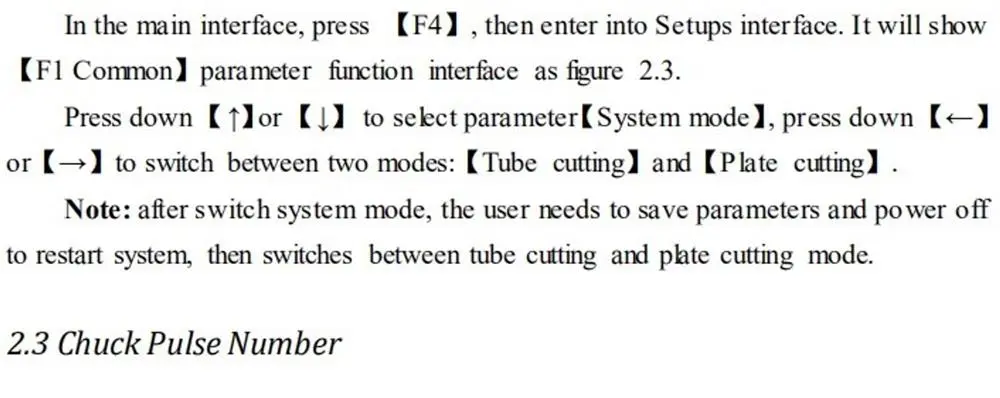

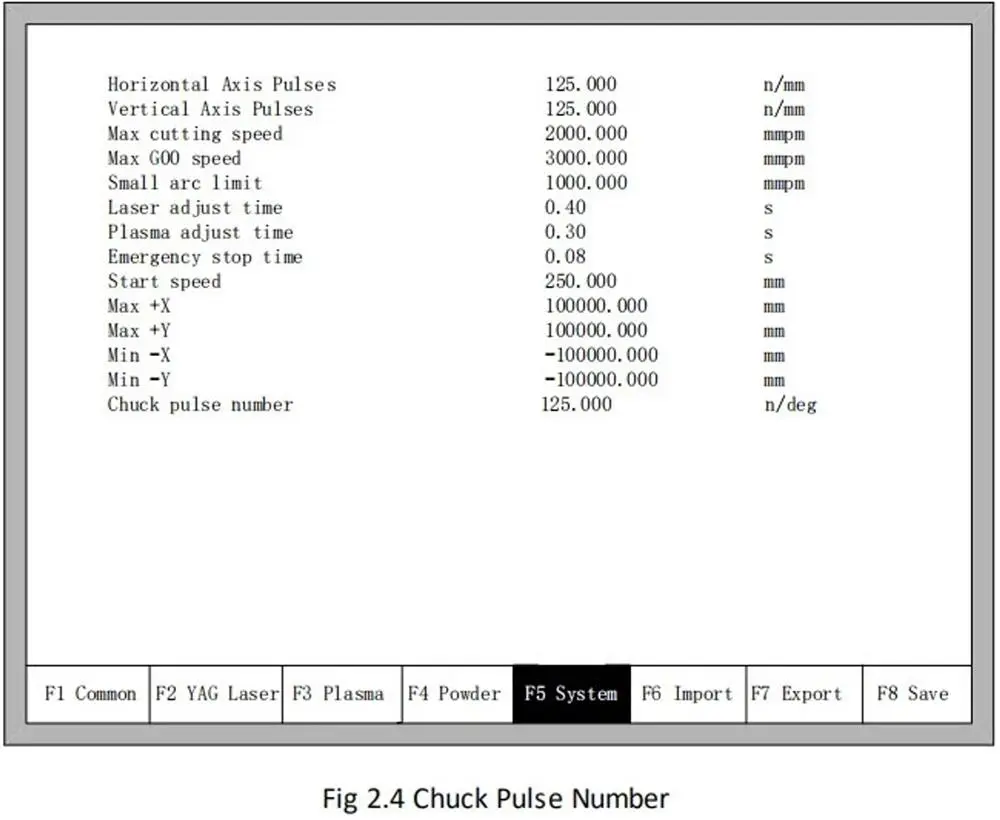

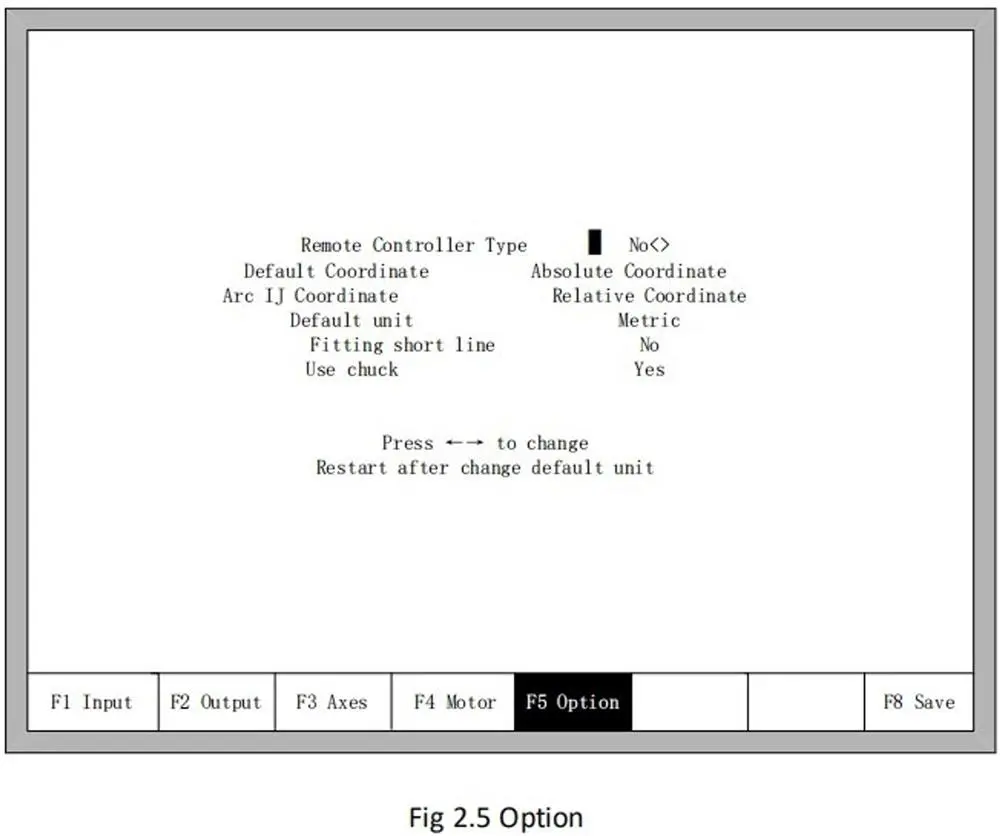

【Chuck Pulse Number】: This parameter sets that chuck needs how many pulses to rotate 1°.

In the cutting tube mode, use【Chuck Pulse Number】 to calculate chuck’s position value

2.4 Whether Use Chuck or not

【Use chuck】When this parameter is set “yes”, (Y) sets angle as unit in G codes; When this parameter is set “no”, (Y) sets length as unit in G codes

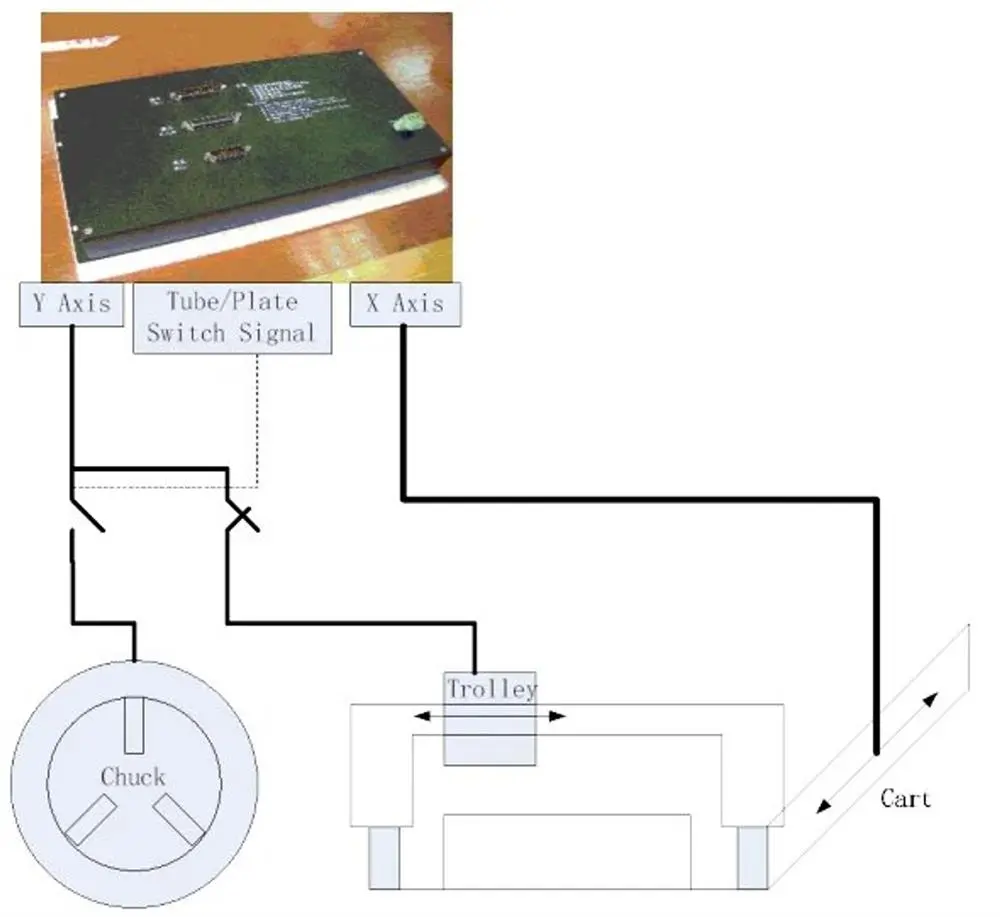

Chapter 3 Tube/plate All-in-one System controller Topology Schematic

As the above figure shows, the signal of X Axis is used for controlling the cart ’s motor; the signal of Y Axis is used for controlling the chuck's or trolley’s motor.

At the same time, only one of the chuck’s and trolley’s motors is always enabled(Using the tube/plate switch signal by the system outputs).

[2]SF-2100S

Type | Data |

Processor | using industrial-grade ARM processing chip |

Display | 7 inches color LCD display, 800 * 480 resolution |

Input/Output | the system to provide the number 13 photoelectric isolation input, 8-way

photoelectric isolation output, including four roads relay output. |

Linkage axes | 3 axes |

Max speed | < 24Meters/Min |

Pulse equivalent | flexible adjustment. |

Storage space | 4G super user program storage capacity, processing program is not

restricted |

Case size | 298 * 202 * 95.2 (mm) |

Working temperature | 0 ℃ ~ + 40 ℃ . Storage temperature: - 30 ℃ ~ + 60 ℃ |

Features:

- The cutting machine CNC system is suitable for all kinds of portable flame/plasma cutting machine, and various advertising,stone and other small desktop cutting machines.

- The system is designed with high reliability, with plasma interference, lightning protection and surge capacity.

- Practical flame/plasma cutting process.

- The available wireless remote control to realize the long distance operation.

- Breakpoints recovery, electrical recovery function of the automatic, automatic breakpoint memory.

- Any choosing passage and perforation point processing function, it can be arbitrary line escapement in machining.

Specification:

Type | Data |

Model | SF-2100S |

Application | cnc cutting machine |

Dimension(L*W*H) | 400x300x200mm |

Certification | CE ISO |

Axis | 2 Axis |

Warranty | One Year |

Interface | USB |

Port | 24input 24output |

Display | 7 Inch LCD |

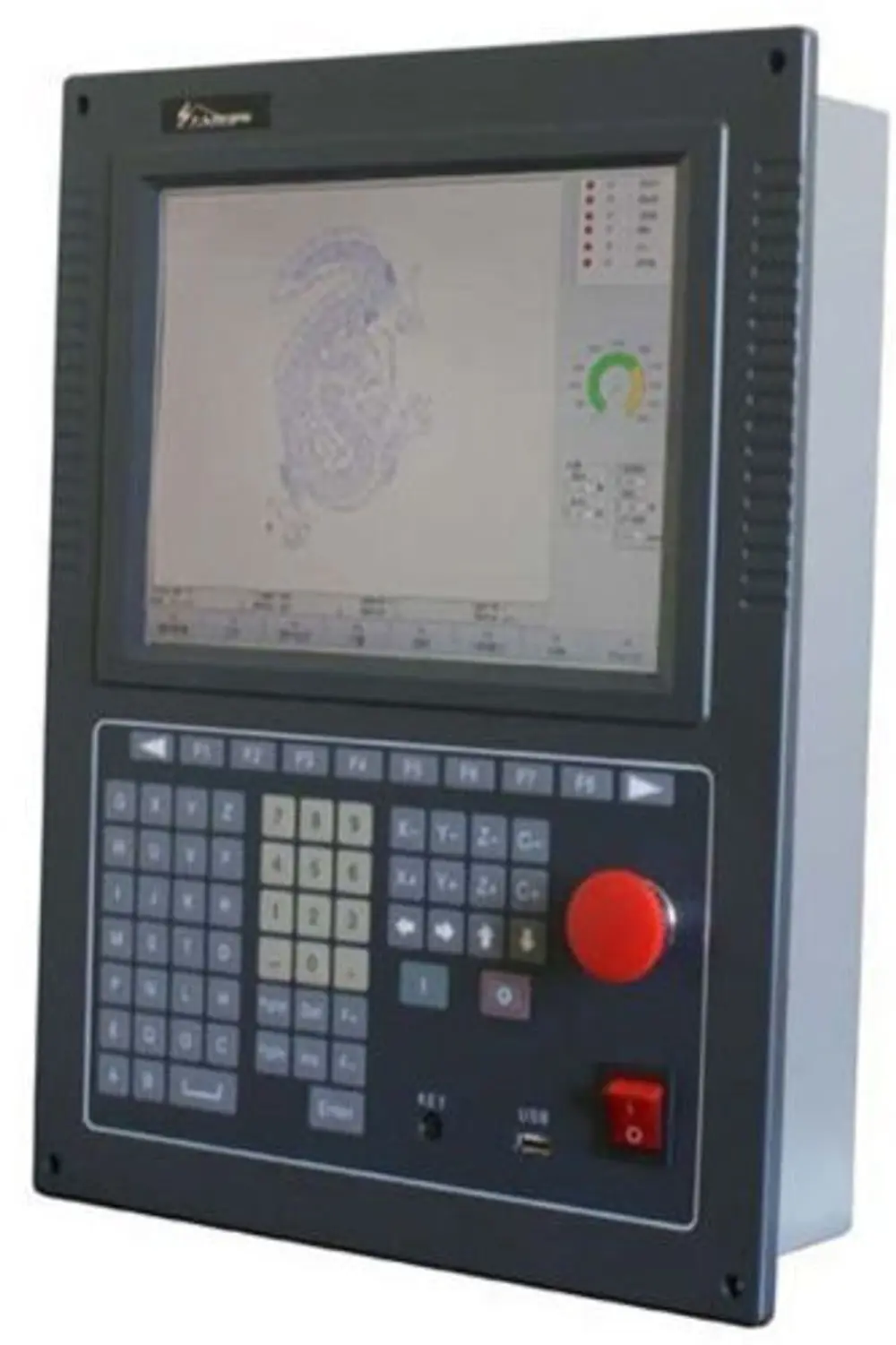

[3]SF-2300S

Type | Data |

Processor | industrial-grade ARM processing chip |

Display | 10-inch color LCD display; |

Input/output | the system provides 16 channels of photoelectric isolation input and 14 channels of photoelectric isolation output |

Number of linkage axes | 2 axes, which can be extended to 4 linkage axes; |

Maximum speed | not less than 24m/min |

Pulse equivalent | flexible adjustment; |

Storage space | 4G super-large user program storage capacity, processing procedures are not limited |

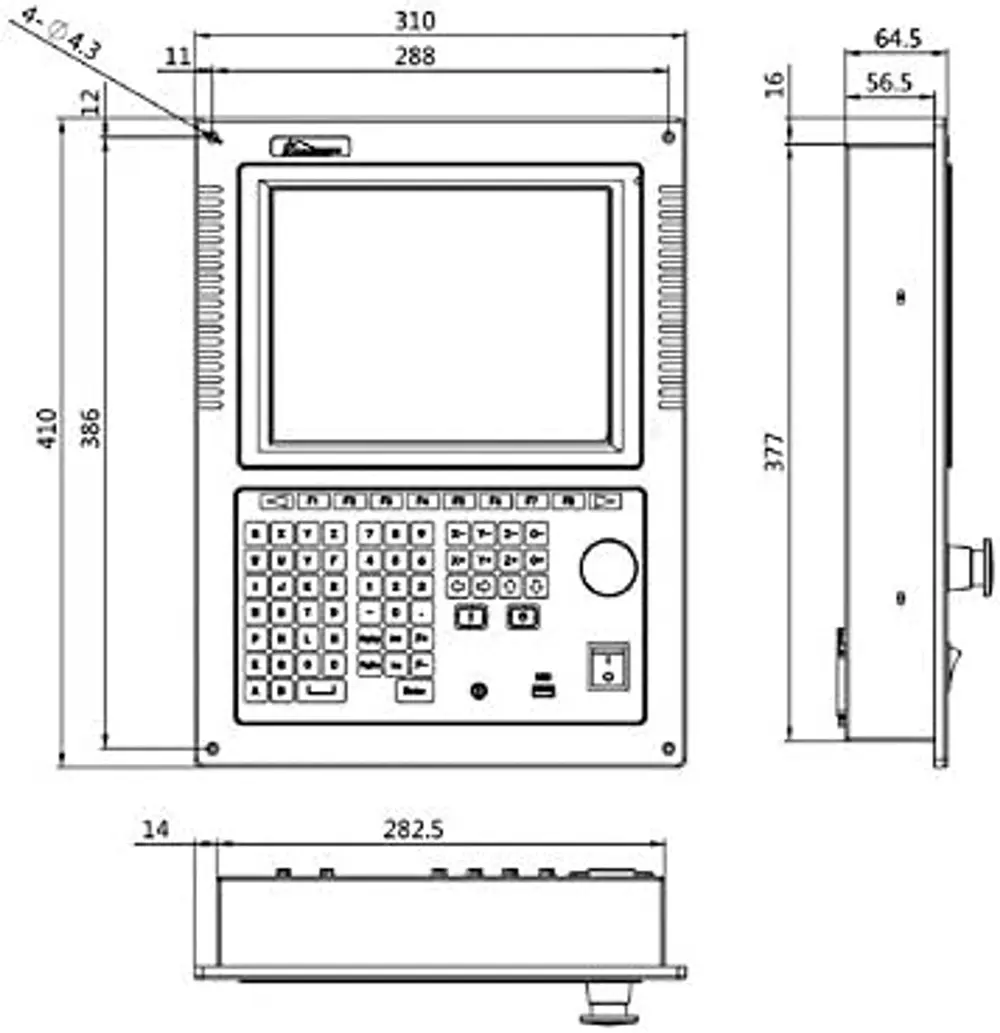

Chassis size | 410×310×119 (mm); |

Operating temperature | Operating temperature: 0℃ ~ +40℃; Storage temperature: -40℃ ~ +60℃ |

AdvantagesSF-2300S-QG cutting machine CNC system is suitable for all kinds of flame/plasma, water knife cutting, laser cutting machine, widely used in metal processing, advertising, stone and other industries.

- The system is highly reliable and has the ability to resist plasma interference, lightning strike and surge.

- Practical flame/plasma cutting technology, automatic corner speed control and elevation control during plasma processing; Remote operation can be achieved by wireless remote control.

- It has the function of slot compensation, detects whether the compensation is reasonable in the program, and makes the corresponding report for the user to choose;

- Breakpoint recovery, automatic power failure recovery function, automatic memory of breakpoint;

- Processing function of optional segment and punch point;

- It has the function of extensional perforation suitable for thick plate and the function of bridging suitable for thin plate;

- In the process of fallback, paragraph selection, breakpoint recovery, and optional punch position, etc., which greatly facilitates the user's control;

- Special small line segment processing function is adopted to make smooth walking, which can be widely applied to metal blanking, etc.;

- Part library with 50 kinds of graphics (expandable), including common basic processing parts;

- Fully compatible with StarCAM nesting software and mainstream nesting software such as FASTCAM;

- English and Chinese operation interface conversion, dynamic graphics display, 1-8x graphics magnification, automatic tracking of moving points, using U disk reading program and timely software upgrade.

Hardware technology index

- It uses the industrial-grade ARM processing chip

- It uses 10.4-inch true color TFT display, resolution 640*480

- The system provides 16-way photoelectric isolation input, 14-way photoelectric isolation output.

- Linkage axis number: 2 axis

- Pulse equivalent: molecular electronic gear, the denominator set range (1 - 65535).

- Running memory 64M, suitable for large processing program

- User program storage space: 2G -4G

- The case size: 410 *310 *119 (mm)

- The operating temperature of 0 degrees to +40 degree

- The storage temperature -40 degree to +60 degree

[4]SF-2310S

Typical Application:SF-2310S-QG cutting machine numerical control system is suitable for all kinds of flame/plasma, waterjet cutting, laser cutting machines, and is widely used in metal processing, advertising, stone and other industries.

Product Specifications:

- Processor: Using industrial-grade ARM processing chips;

- Display: 10-inch color LCD display;

- Input/Output: The system provides 16 optically isolated inputs and 14 optically isolated outputs;

- Linked axis number: 2 axes, which can be expanded to 4 linked axes;

- Maximum speed: Not less than 24 meters/min;

- Pulse equivalent: Flexible adjustment;

- Storage space: 4G super-large user program storage capacity, unlimited processing programs;

- Chassis size: 410×310×119 (mm);

- Working temperature: 0 ℃ ~ +40 ℃; Storage temperature: -40 ℃ ~ +60 ℃;

Features:

- The system is designed with high reliability, having the ability to resist plasma interference, lightning strikes, and surges.

- Practical flame/plasma cutting process. During plasma processing, it automatically completes corner speed control and height adjuster control; remote operation can be achieved with a wireless remote controller.

- It has the function of cutting seam compensation and detects whether the compensation in the program is reasonable, and makes corresponding reports for users to choose from.

- Breakpoint recovery, automatic power-off recovery function, and breakpoint automatic memory;

- The function of selectively processing segments and perforation points;

- It has the extended perforation function suitable for thick plates, and the bridging function suitable for thin plates;

- In the functions of retreat, segment selection, and breakpoint recovery, the perforation position can be selected optionally, which greatly facilitates the user's control;

- It adopts a special small line segment processing function, with smooth movement, and can be widely used in metal blanking, etc.;

- It includes a parts library with 50 types of graphics (expandable), including commonly used basic processing parts;

- It is fully compatible with StarCAM nesting software, and is also compatible with mainstream nesting software such as FASTCAM;

- Chinese-English operation interface conversion, dynamic graphic display, 1-8 times graphic zoom, automatic tracking of moving points, U disk to read programs, and timely software upgrade.

[5]SF-RF06A remote

Features:

- High sensitivity button

- Anti-static interference

- Long controlling distance above 20M

- 2.4GHz RF transmission technology

Code-match description:After the receiver is powered on, Press the button “CLOSE” on remote control until the red light twinkles, then release “CLOSE”, and press any two numeric keys in turn, red light out, code-match finished.The two numbers you pressed are the encoder of this remote control. We need to set different encoders when there are several machines that are connected with remote control.In the CNC controller, enter “Parameter ”- ”Control”, set “WIRED-0/RC05-1/RC06-2" as 2.

Controller size: 135 *55*16mm

Funtion key number: 24

Wiring diagram

📄Fangling THC controller

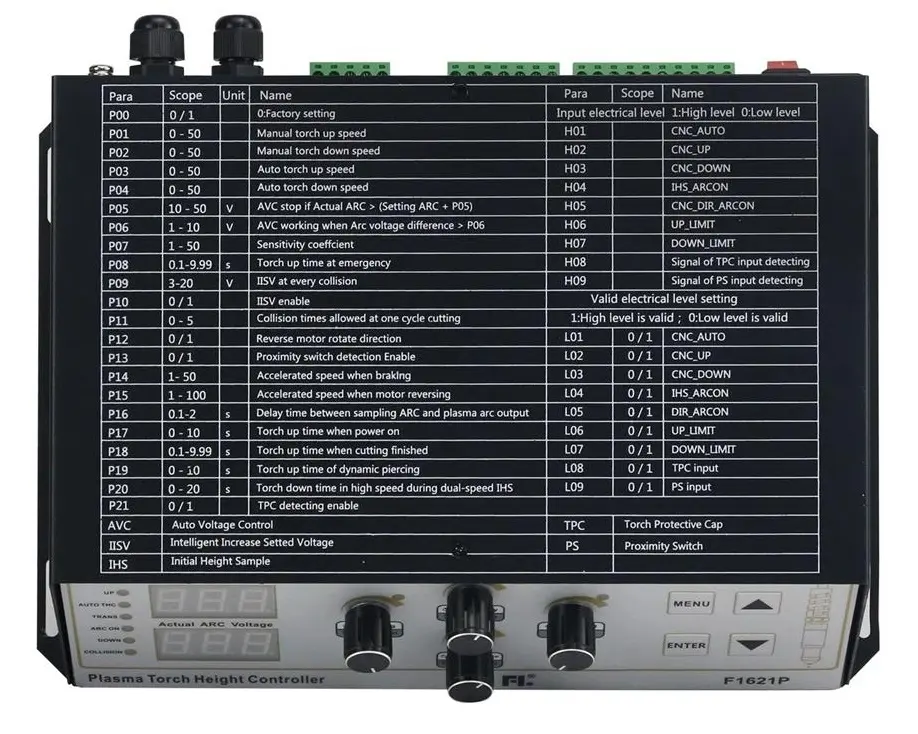

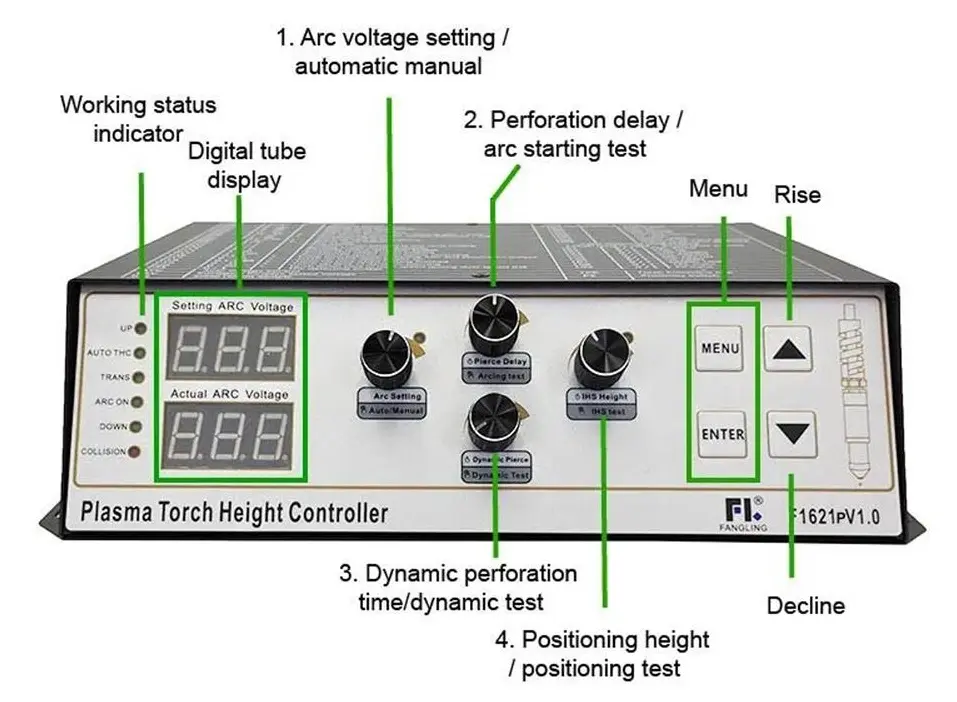

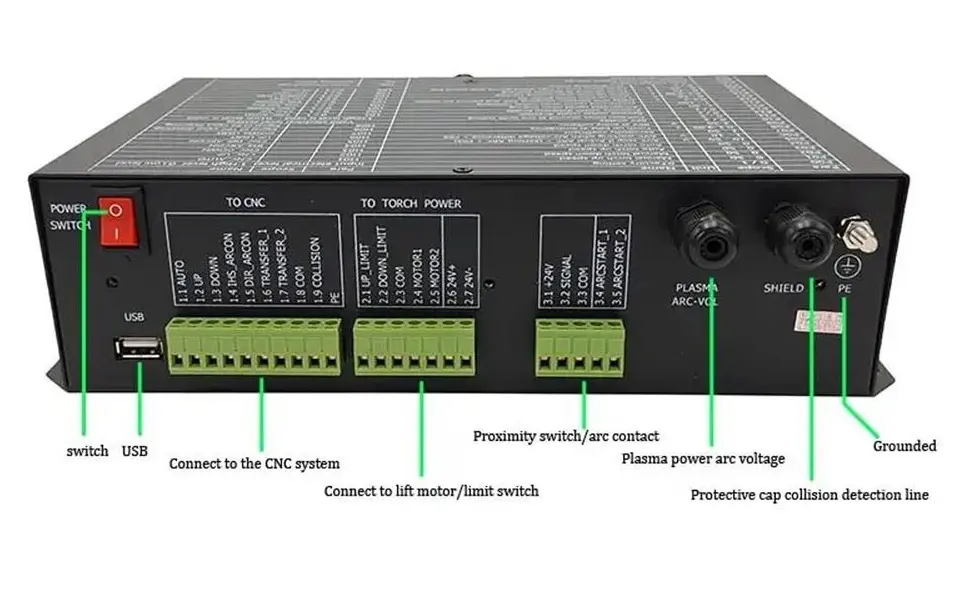

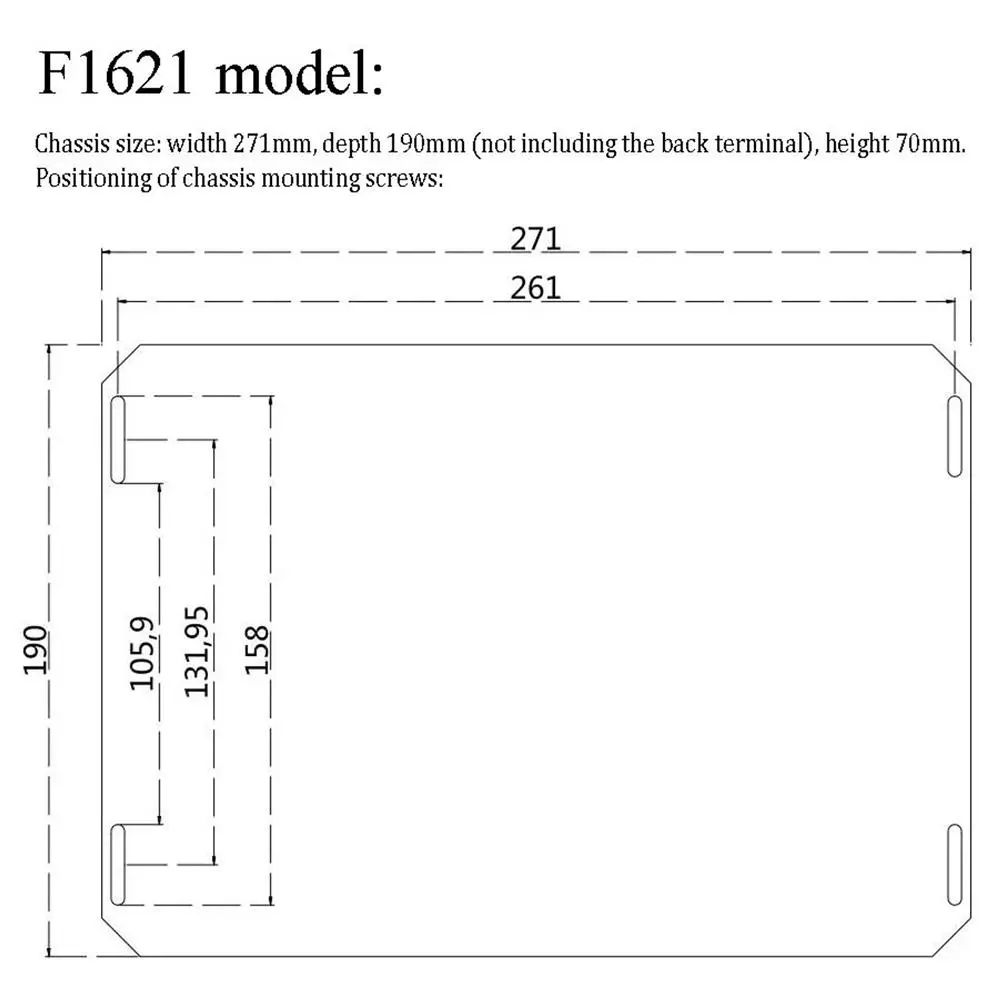

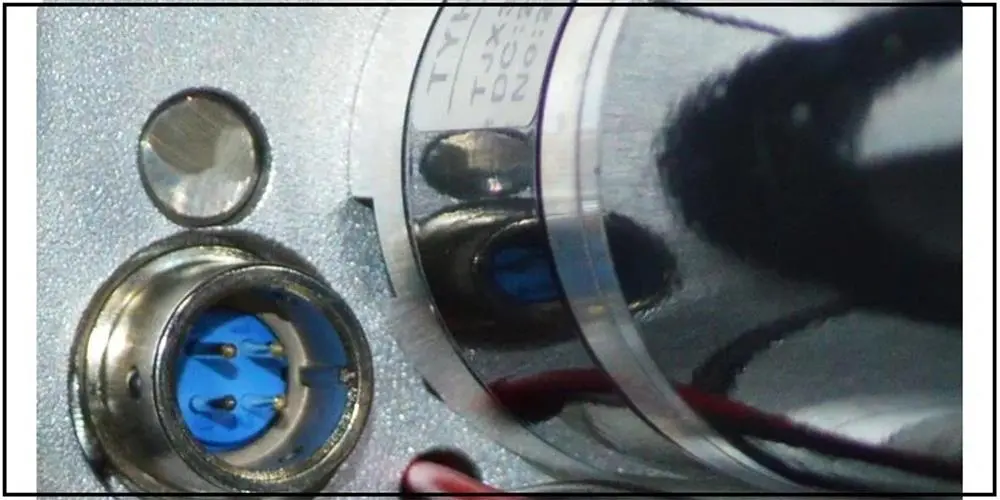

[1]F1621P

Equipment introductionF162X series digital plasma arc voltage height controller is a series of products developed by our company, which are easy to operate, stable in performance, complete in function and high in cost performance, based on the on-site usage of plasma power supply and absorbing the advantages of many arc voltage height controllers at home and abroad. This series of equipment uses the basic constant current characteristic of plasma power supply to detect the change of plasma torch height by detecting the change of plasma arc voltage, so as to control the height between the torch and the workpiece in real-time. It is suitable for height control of plasma power cutting torch with constant current characteristics or constant current characteristics within a certain voltage range. It is especially suitable for cutting torch height control of various cutting machines. This series of equipment is light and portable, easy to operate and to use. All keys and knobs are designed with humanity, comfortable, and convenient.

Type | Data |

Brand Name | Fangling |

Dimension(L*W*H) | 271*210*70(mm) |

Weight | 2.5KG |

Product Model | F1621P |

Lifting motor | DC24V DC motor |

Arc pressure sampling accuracy | 0.2V |

Output power | ≤100W |

Operating temperature | 0℃-50℃ |

Partial pressure ratio | 99:1 |

Arc voltage setting range | 30-600V (real-time change via panel knob) |

[2]F1650

Type | Data |

CPU | High Performance ARM Processor |

Regulator Motor | Position Control Type Stepper / Servo Motor |

Position Control Accuracy | ±0.001mm |

Maximum Pulse Frequency | 160KHz |

Maximum Operating Speed | 30m/min |

Chassis | Full-steel Structure |

Working Voltage | DC +24V |

DC Motor Output Power | Maximum 45W |

Voltage Divider Ratio | 100:1 or 50:1 |

Arc Voltage Setting Range | 30V~600V |

F1650 fine plasma arc pressure regulator adopts high-performance ARM9 processor and ultra-large-scale programmable device FPGA to realize precise, fast and stable arc pressure height control of plasma lifter. It achieves better cutting effect, smoother cutting surface and better perpendicularity. F1650 adopts an aluminum front panel, which is more beautiful and grander, 5 inches high-definition color screen display, full digital button operation, so that its operation of parameter settings is more convenient, intuitive. There are two ways of connecting with the CNC system, RS232 bus and IO.

Functional Characteristics

- Support servo, stepper and DC three motor lifts.

- In position control mode, support arc pressure tracking mode and height tracking mode.

- Supporting fine 1:1 small circular hole cutting process

- Support RS232 interface, adopt Modbus protocol and system bus connection to reduce wiring.

- All digital keyboard, high definition color screens, graphical user interface, convenient for user operation.

[3]F1628D

Type | Data |

CPU | High Performance ARM Processor |

Monitor | LED Digital Tube |

Interface | I/O Wiring, No Welding Needed |

Driving Motor | Full-bridge MOSFET Driving Circuit. Max Power 45W |

Chassis | Full-steel Structure |

Working Voltage | DC +24V |

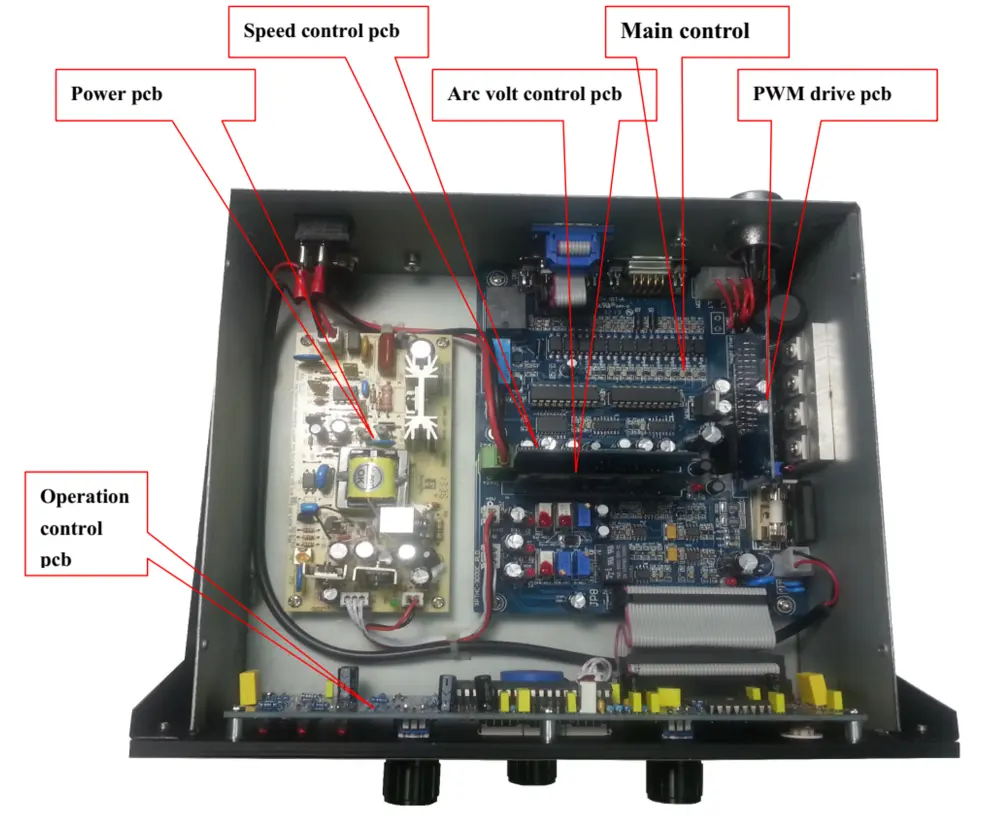

F1628D Arc Voltage Torch Height Controller concludes multiple features from other models. Based on two industrial-level ARM chips which bring the working stability to the next level. System responds faster. Better communication with Shanghai Fangling CNC System.

Divided-body Type, have operating panel, main device, and Voltage-dividing board. Simple installation, better anti-interference ability. RS485/CAN Communication protocol, and Modbus protocol to ensure the correctness of data transfer.

Operation Panel

- Divided-body Type

- Support DC Motor

- Front Panel connected by CAN bus

- CAN bus communication with system, allow more customization

- DC 24V Input,deviation<1V,two speed positioning,Maximum power 100W

Processor

- CPU: Two High-performance ARM processor on panel and main device

- Monitor: HD LCD Digital-Tube

- Interface:RS485 between panel and main device, Modbus for data transfer. Wiring between main device and voltage-divider.

- Motor: Full-bridge MOSFET driving circuit. Max Current 5A

- Chassis: Full-steel structure, prevent radiation and interference. ESD function

[4]F1629D

Brand:Fangling

Model:F1629 (F1630 was not produced)

Product description:

- This device is portable, easy to operate, easy to use, all buttons and knobs user-friendly design, comfortable and convenient.

- The front panel for F1629 is vertical and the regulator is separate from the regulator, which is mainly used in gantry type cnc cutting machines.

- High pressure regulator type 1629 arc plasma power is based on the use of the site, many advantages of high arc absorption devices at home and abroad, the development of a simple operation, stable performance, complete function, cost-effective products. The characteristics of this equipment using plasma power supply basic constant current, to detect changes in plasma torch height by detecting changes in plasma arc voltage, real-time control between the torch and workpiece height.Particularly suitable for portable, table, gantry type cutting torch height control.

Type | Data |

Operating voltage | rated DC 24V (power range 22V - 35V) |

Drive mode | PWM (pulse width modulation) continuous speed regulation |

Arc voltage sampling accuracy | 0.2V |

Arc voltage regulation accuracy | 1V |

Partial pressure ratio | 100:1 |

Output current | 0A-3A (maximum output current is 5A) |

Output power | Max 100W |

Initial position | proximity switch initial positioning |

Storage | 8G |

Operating temperature | 0 ~50 ℃ |

Storage temperature | -40℃~60℃ |

Technical parameters:

- LDC24V DC motor.

- Contact cap initial positioning.

- The cutting torch lifting speed: maximum speed and lifting mechanism.

- Arc pressure setting range: 30V~600V, can be changed in real time through the panel knob.

- Max cutting speed: depending on the maximum speed of the lifting mechanism.

- Overload protection: automatic overload, overheat, under voltage protection, power supply protection.

📄Starfire THC controller

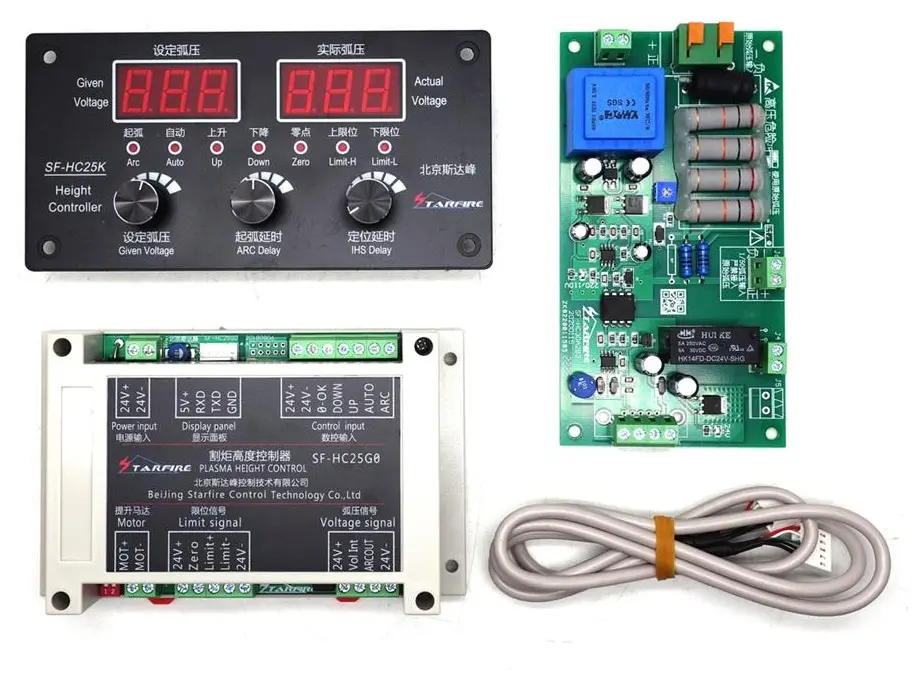

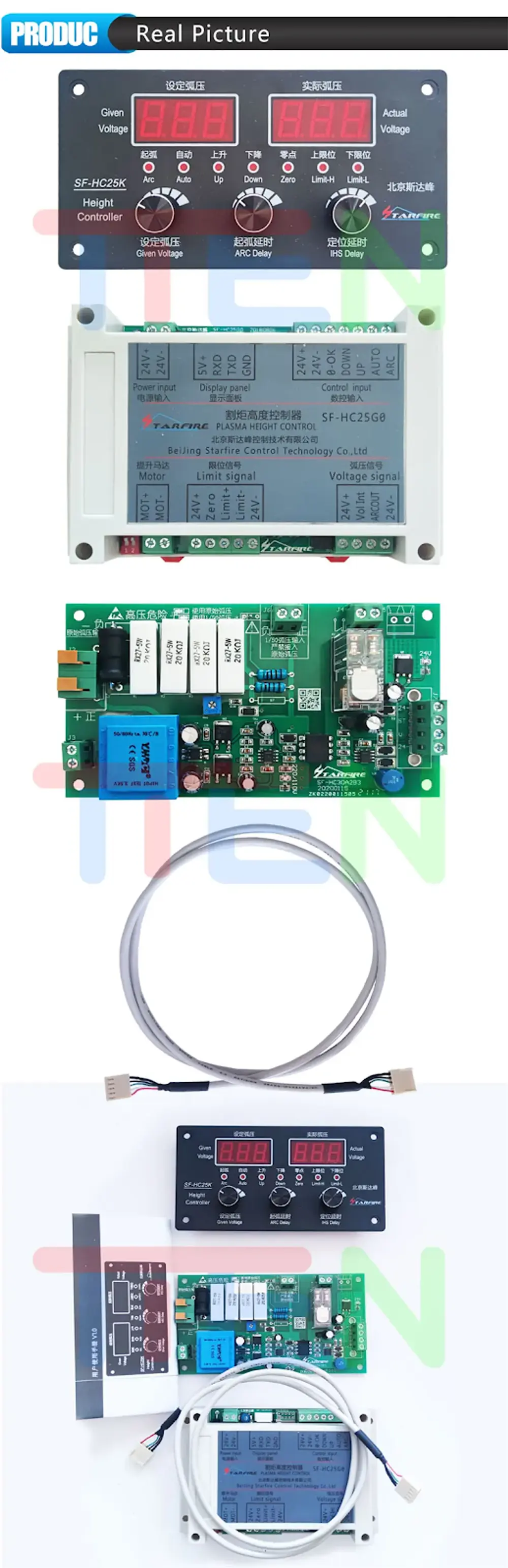

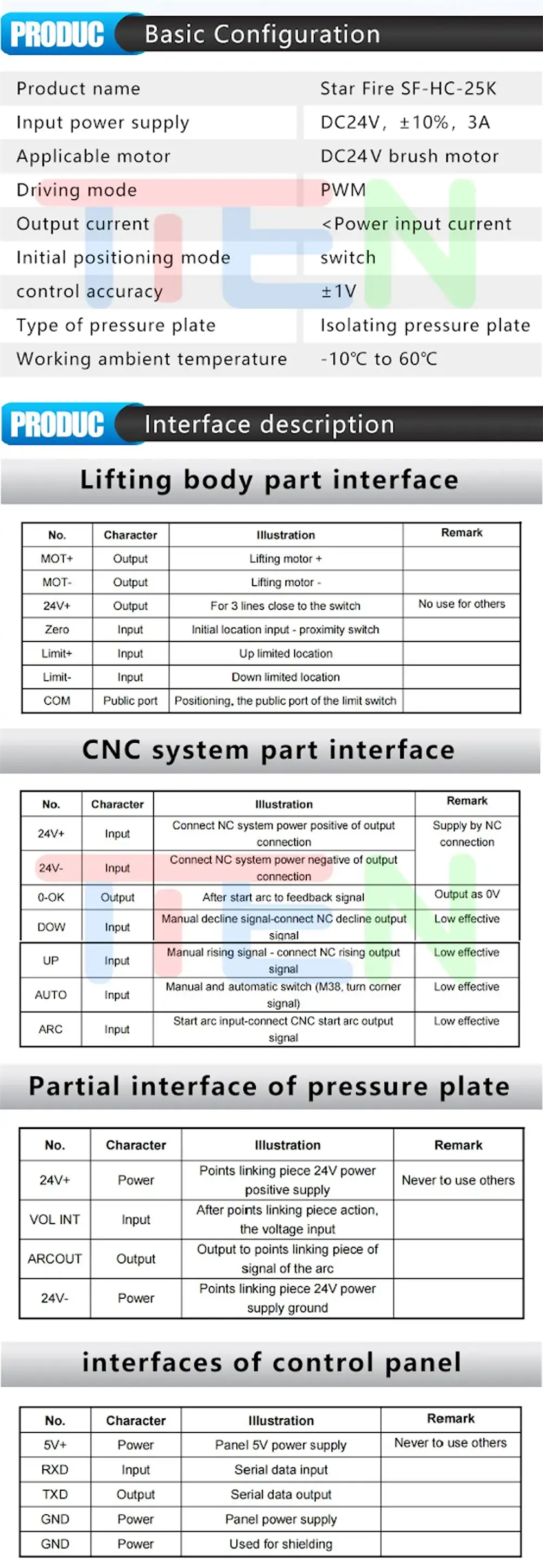

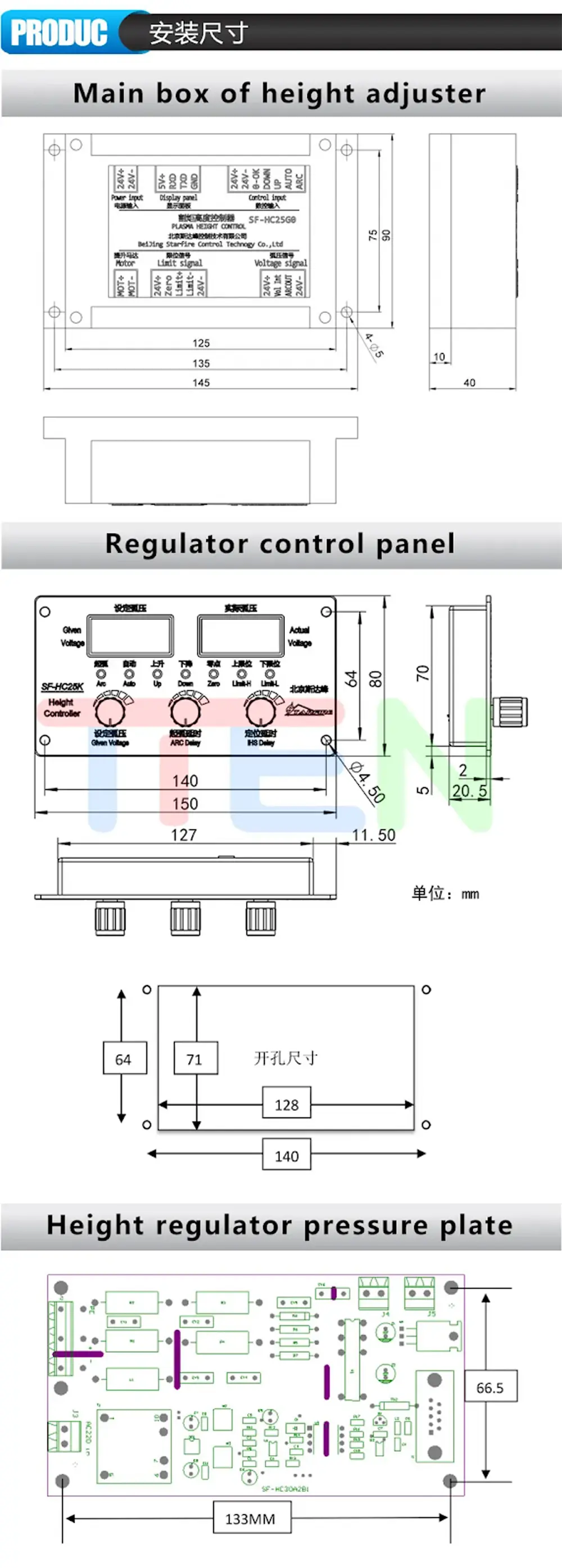

[1]SF-HC25K

Technical Features

- This product adopts 32-bit arm as the core,two groups of three digital tube display, using the numerical control mode. Internal do not contain linear adjustment devices, greatly improve the stability.Speed parameters can be changed, it can make any change according to the lifting mechanism and plasma source power.

- The circuit adopts the SMT without any adjustable elements; the all-digital technology assures the high reliability of product.

- Simple operation,two groups of digital tube displays set arc voltage and actual arc voltage, concise and straightforward. Only three knob to set parameters.

- The interfaces are simple and easy to control, suitable for all numerical control system of plasma cutting, and can also use alone.

- Adopting the proximity switch initial positioning method.

- PWM output, speed adjustable level 255, precise control of motor speed, several current setting, and short circuit protection.

- Anti-collision function, when the nozzle touches the plate, CNC controller will quickly lift the torch to a certain distance, and protect the nozzle effectively.

- All input and output adopt photoelectric isolation, plasma voltage feedback using linear photoelectric isolation, and independent power source, it can be well compatible with various brands of imported plasma source power with voltage-divide.

- Integrate judgment and feedback function of arc start success.

Main Technical Data

- Power Supply: DC24V±10% 3 A

- Applicable Motor: 24V DC Brush Motor

- Drive Mode: PWM

- Output Current: <input current of power supply

- Initial Positioning Method: proximity switch(Normally open and close is set through jumper cap)

- Max Control Precision: ±1 V

- Working Environment Temperature: -10~60 ℃

- Detecting System: isolation of arc voltage divide board(B2version)

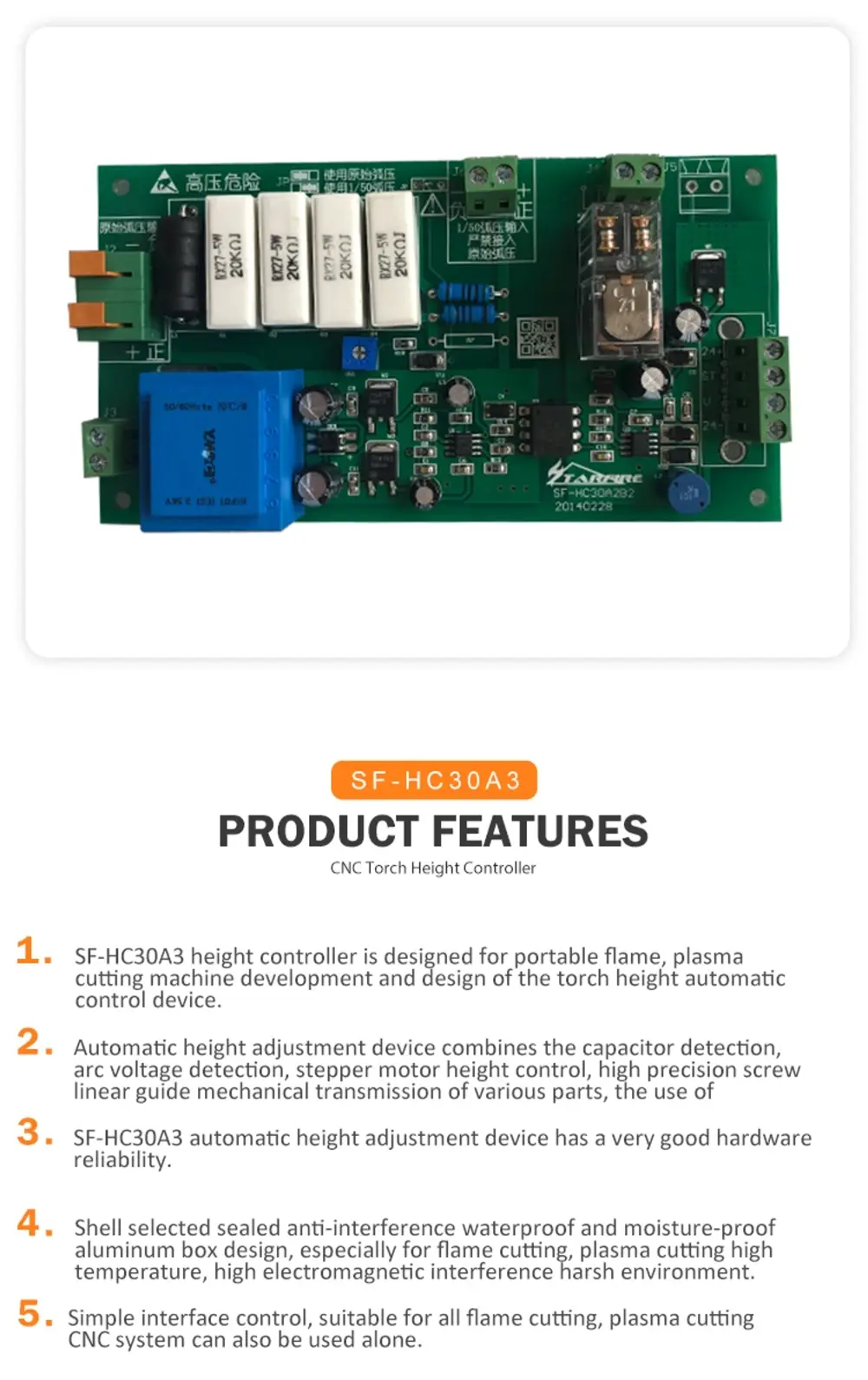

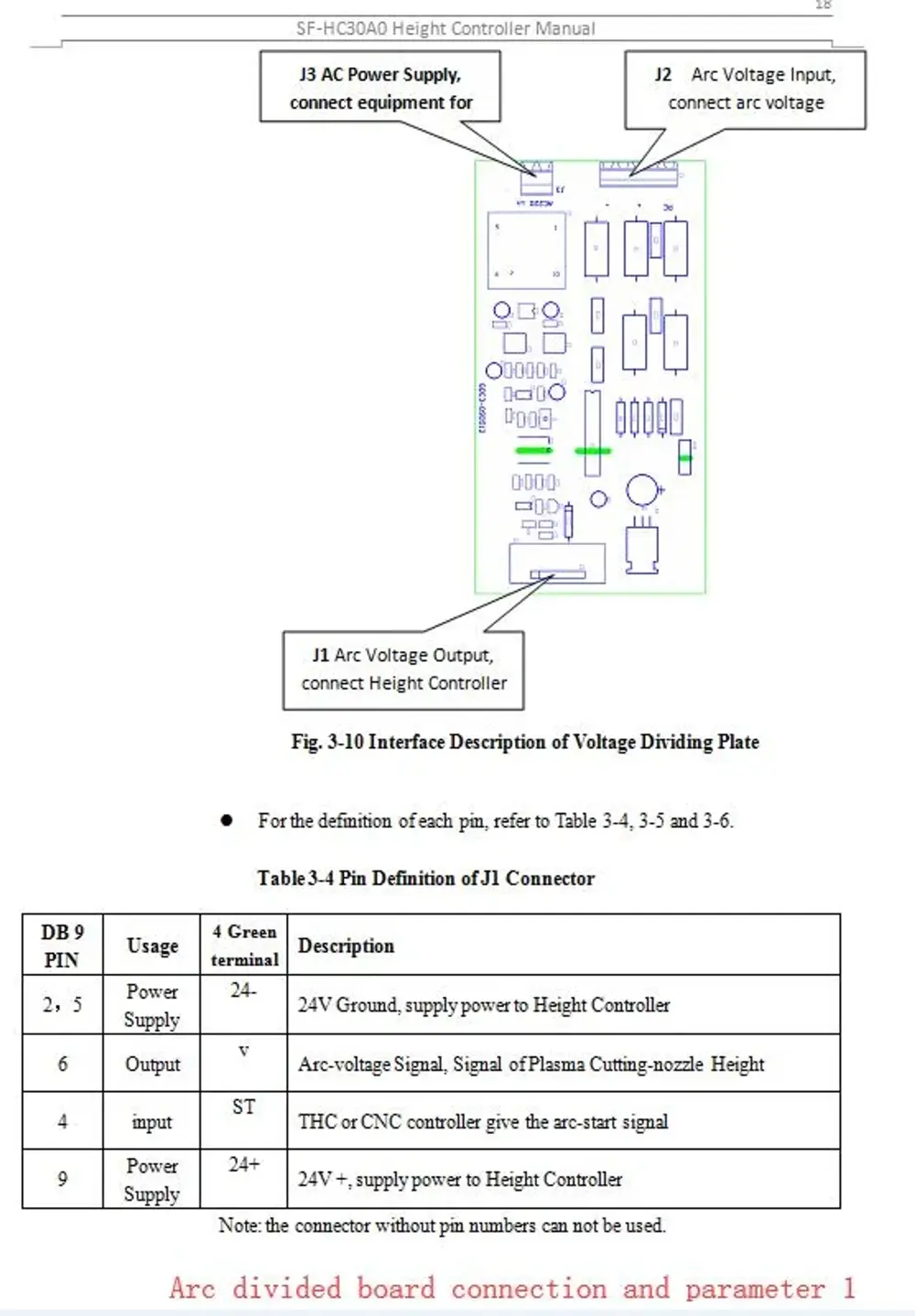

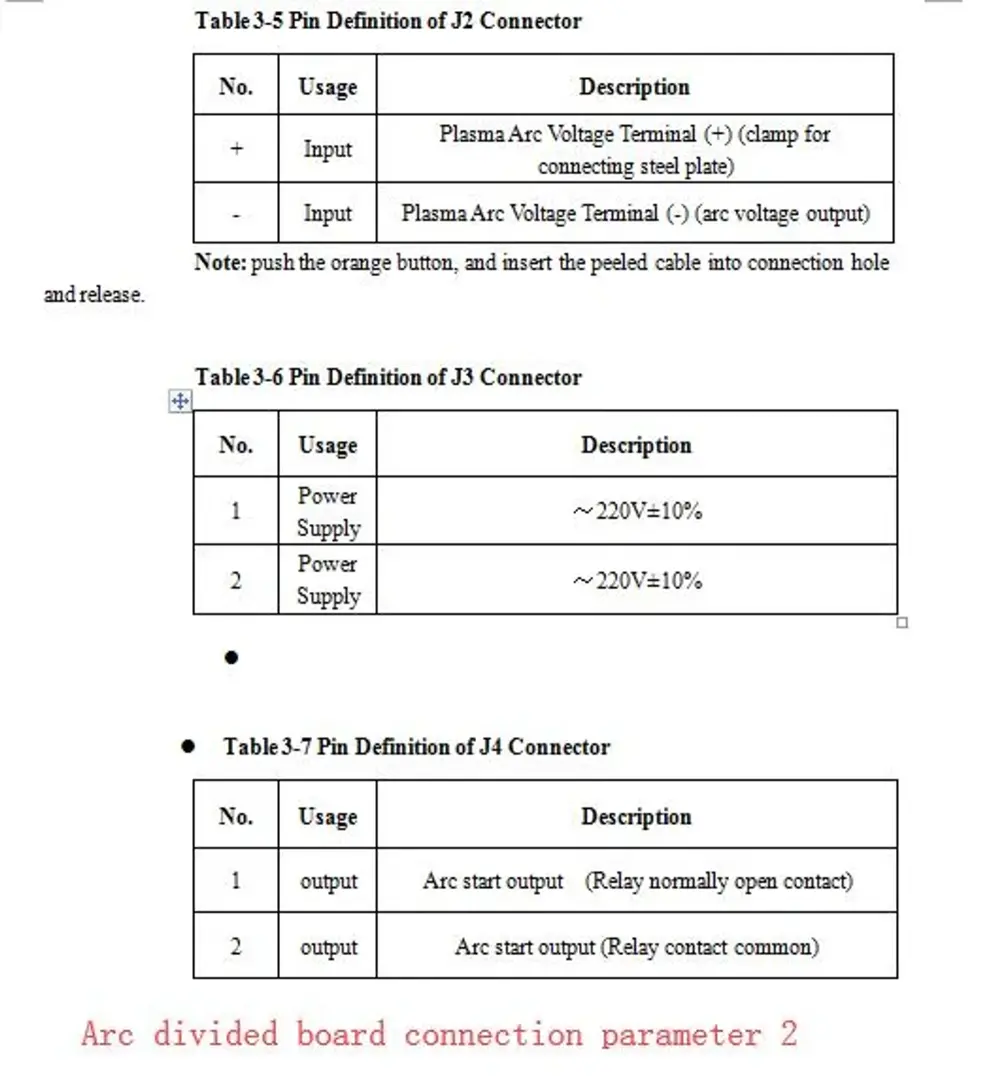

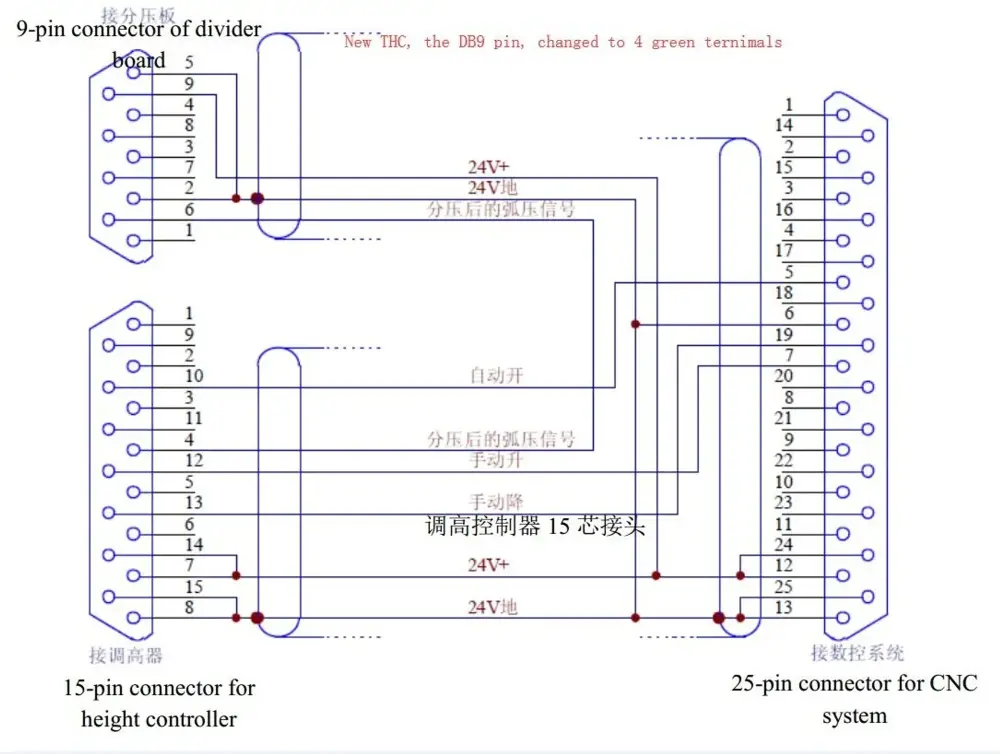

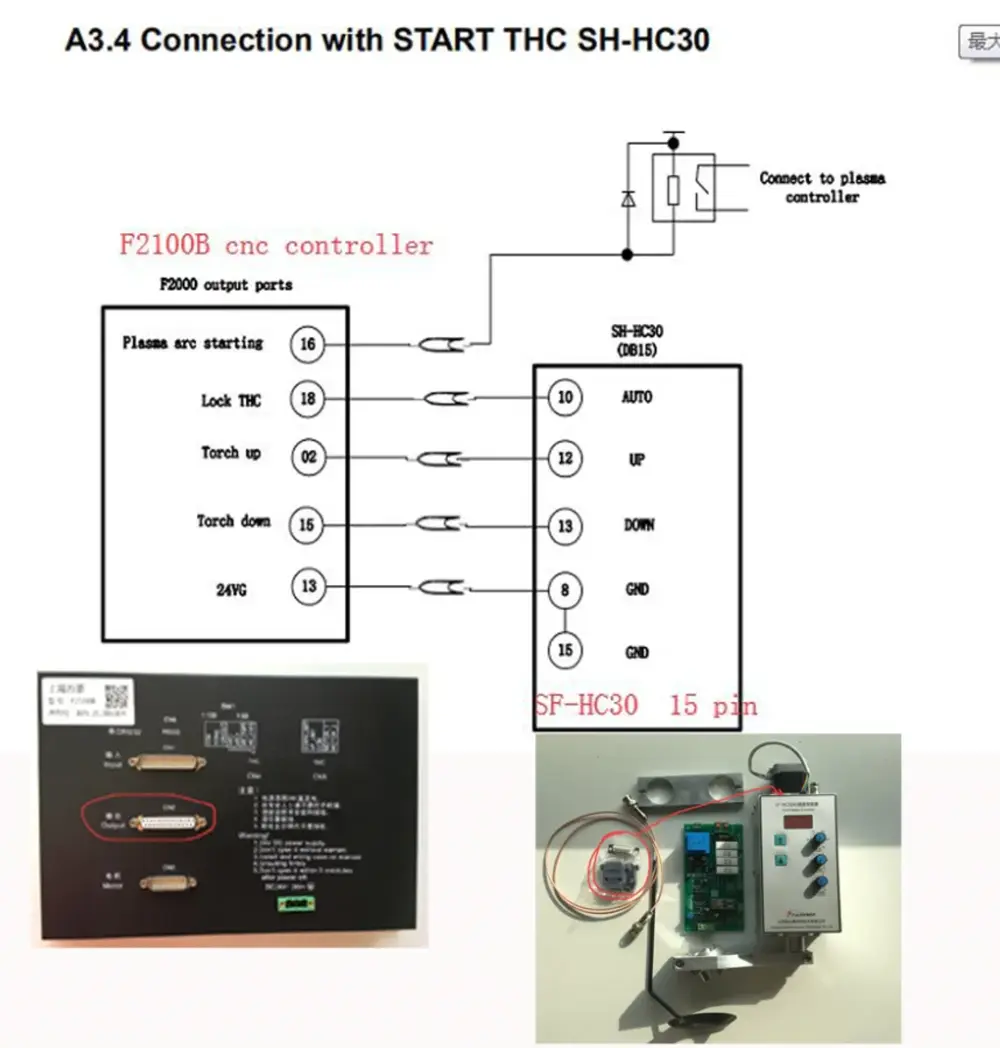

[2]SF-HC30A3

Technical characteristics:

- SF-HC30 height controller is designed for portable flame, plasma cutting machine development and design of the torch height automatic control device. Automatic height adjustment device combines the capacitor detection, arc voltage detection, stepper motor height control, high precision screw linear guide mechanical transmission of various parts, the use of micro-single-chip computer control, in the automatic calibration function with the direct display torch height.

- SF-HC30 automatic height adjustment device has a very good hardware reliability. Shell selected sealed anti-interference waterproof and moisture-proof aluminum box design, especially for flame cutting, plasma cutting high temperature, high electromagnetic interference harsh environment. Simple interface control, suitable for all flame cutting, plasma cutting CNC system can also be used alone.

- SF-HC30 height controller is easy to use, easy debugging, low price, adhering to the characteristics of Staud products has always been "imported performance, domestic prices."Welding and cutting equipment manufacturers is the ideal matching products.

2.Specification:

Type | Data |

power requirement | DC 24 v ± 2 V3 A |

applicable motor | 17 hs (42) series of stepping motor |

manual adjusting range | 0 ~ 100 mm |

automatically adjustable high control range | 3 ~ 30 mm |

automatically adjustable high adjustment speed | 3000 mm/points |

control accuracy | + / - 0.5 mm |

box body size | 155 x 87 x 71 mm |

working environment | - 10 ~ 50 °C |

📄HYDTHC THC controller

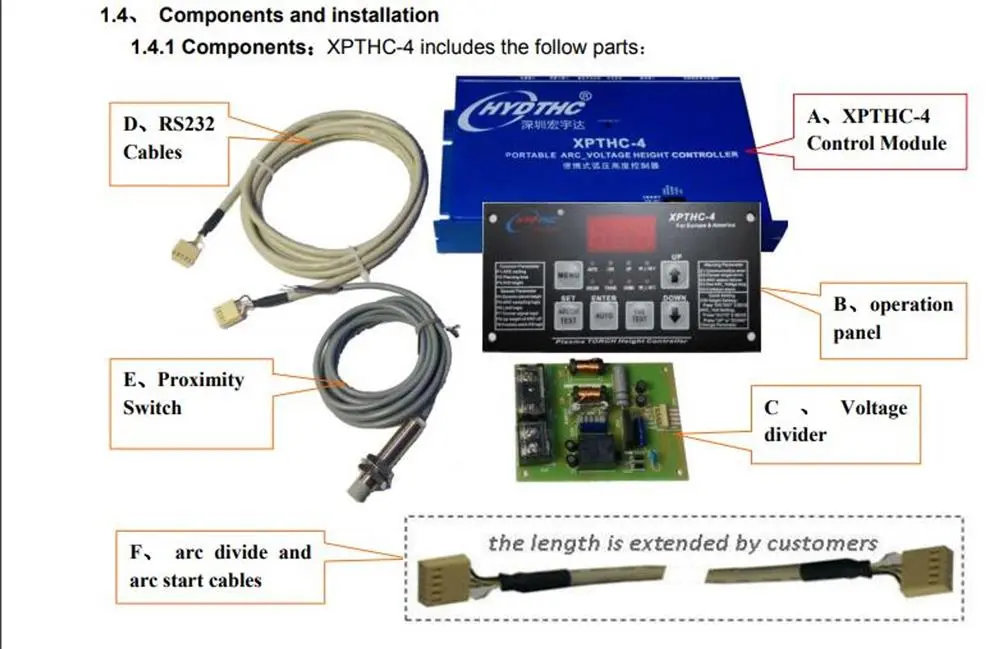

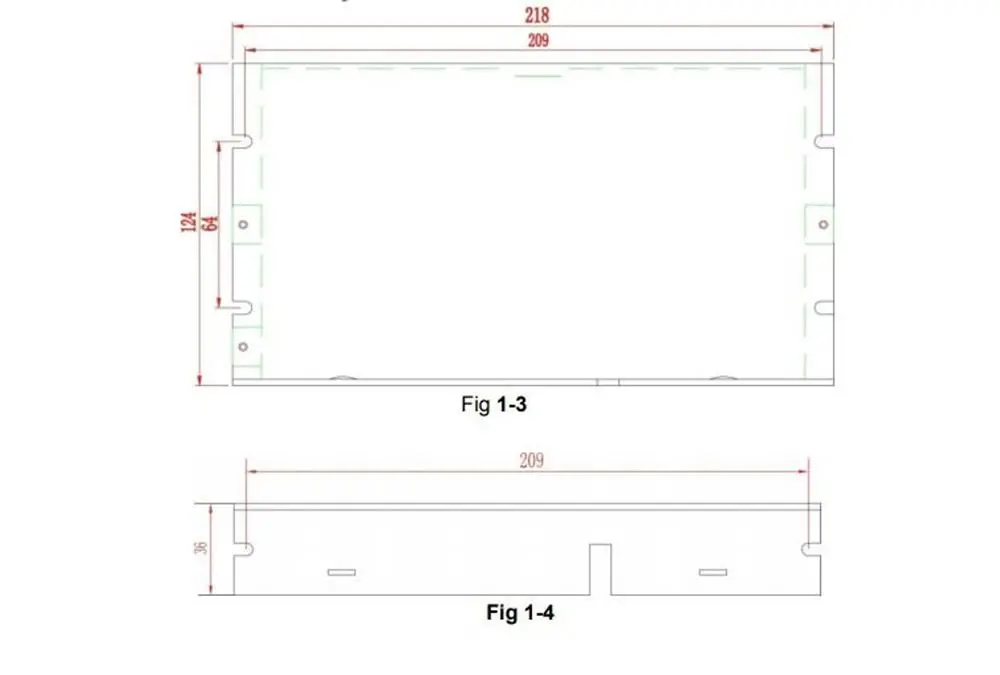

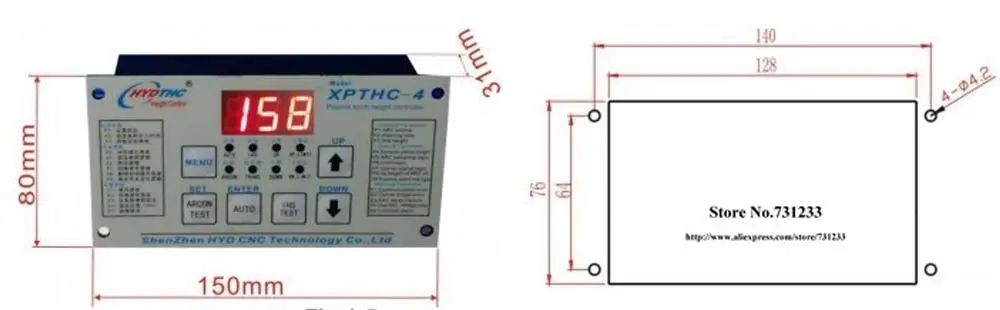

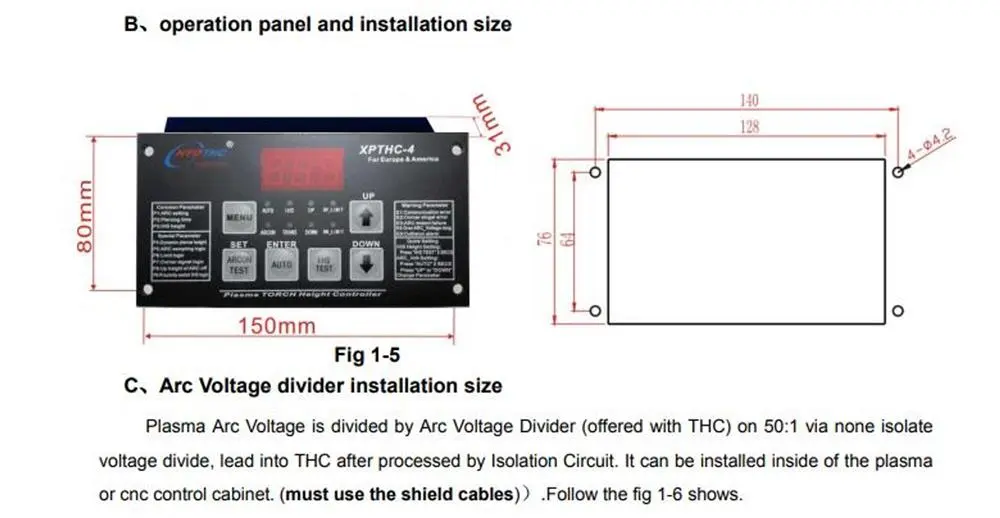

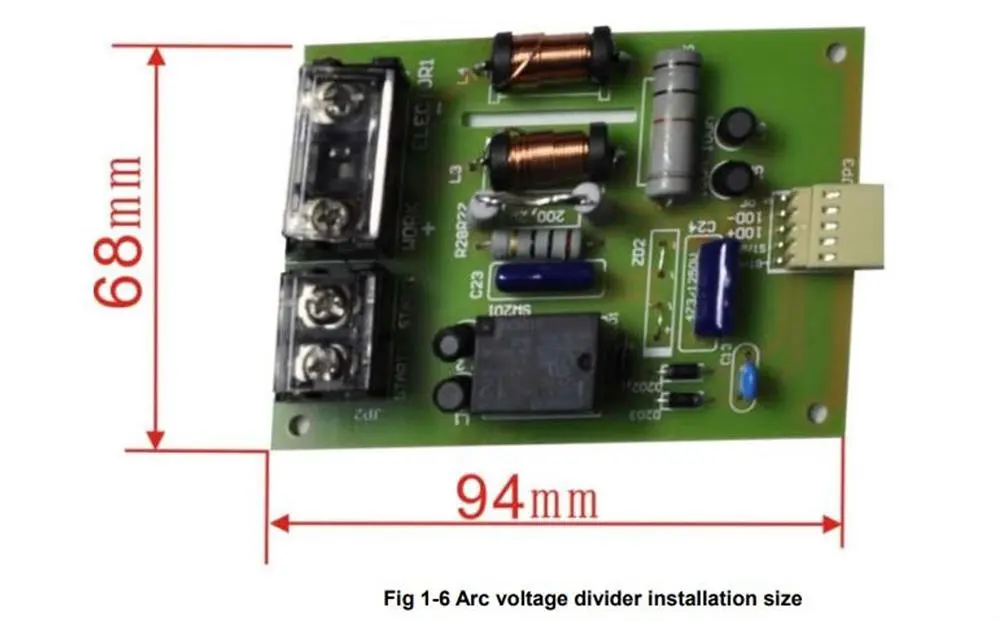

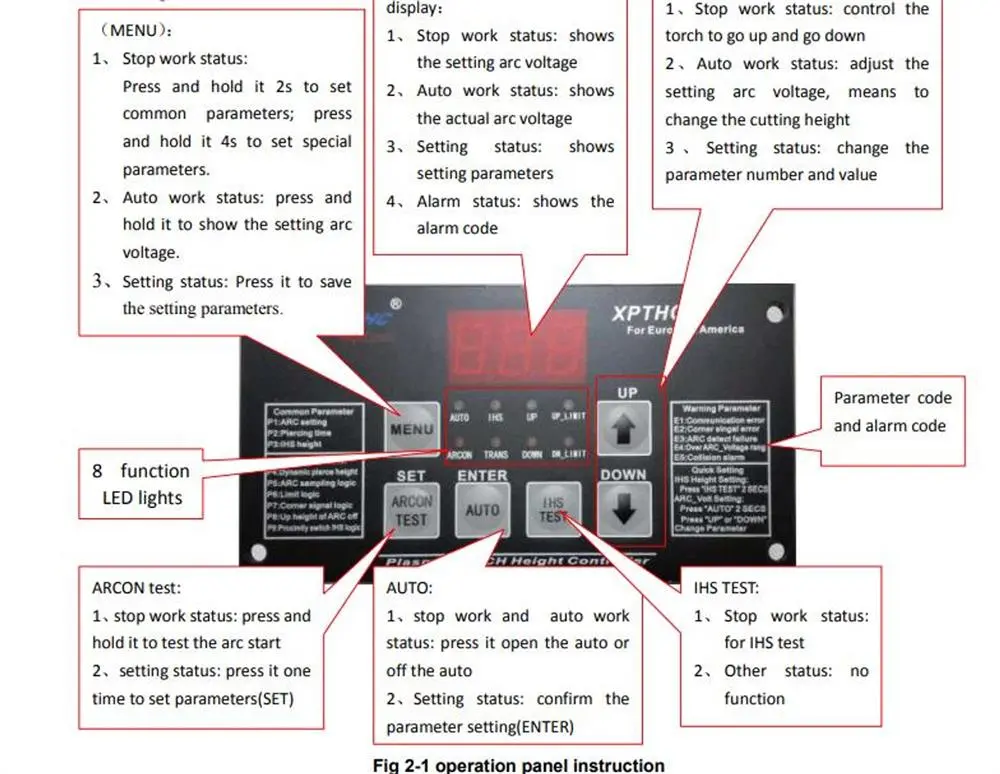

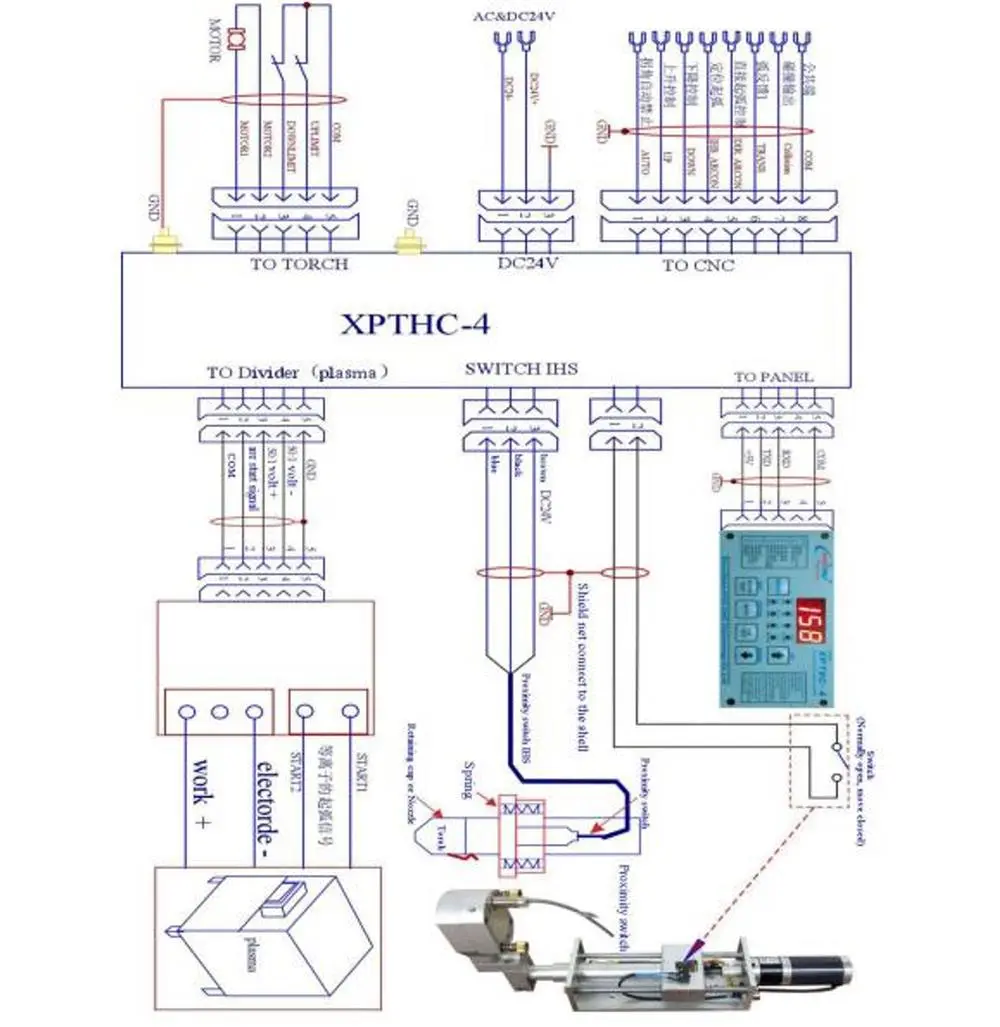

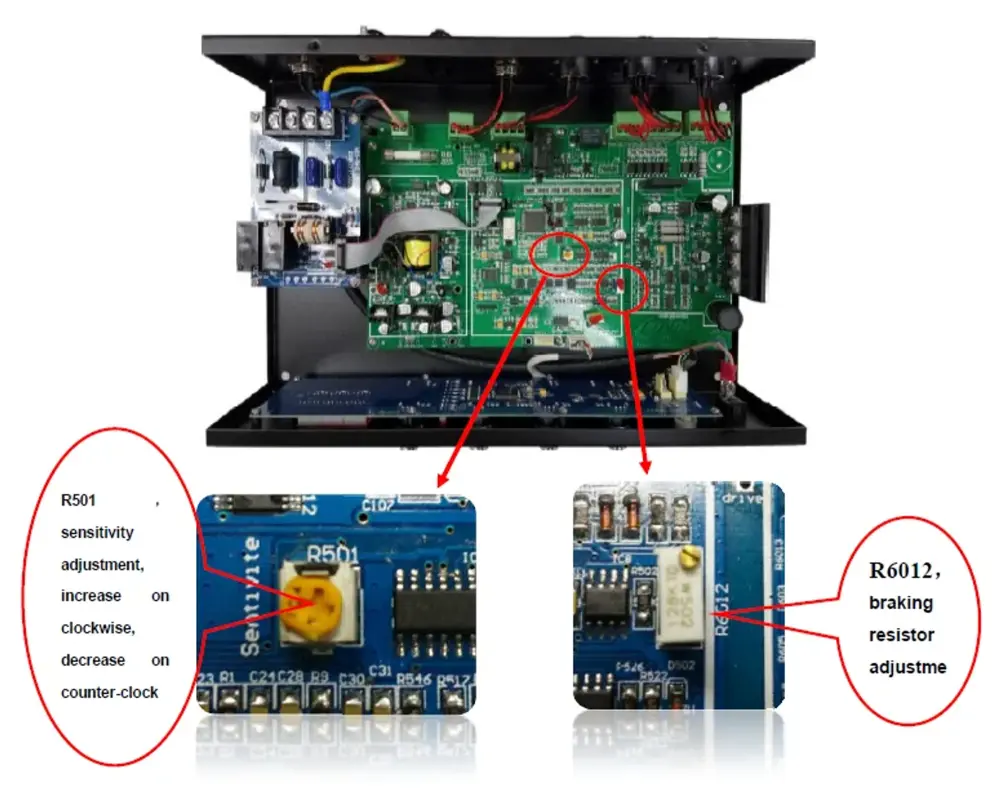

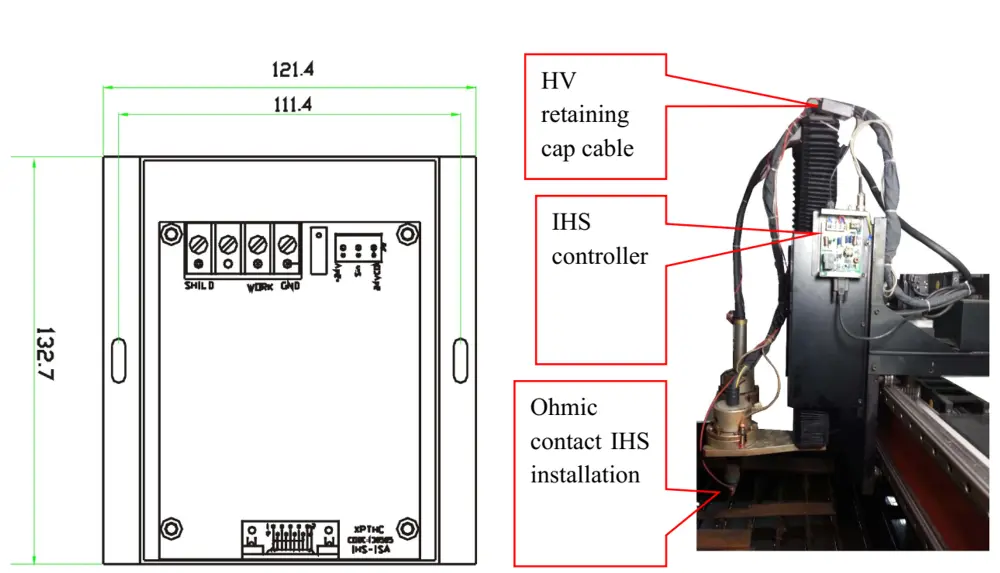

[1]XPTHC-4H

Model:HY D XPTHC-4H(XPTHC-4 is not produced now.)XPTHC-4H is a new design that can completely replace the arc voltage of the old XPTHC-4HBased on the existing functions of the old model, the new XPTHC-4H adds many new functions:

- Better operation, new operation panel design.

- Added Dynamic Pierce, protect torch retaining cap.

- Better anti-interference design.

- Better work stability.

Basic Parameter:

- IHS:Switch IHS & Proximity switch IHS; Do Not support the retaining cap HIS

- Work way: check the arc enable output, 200mA optical coupler OC door output

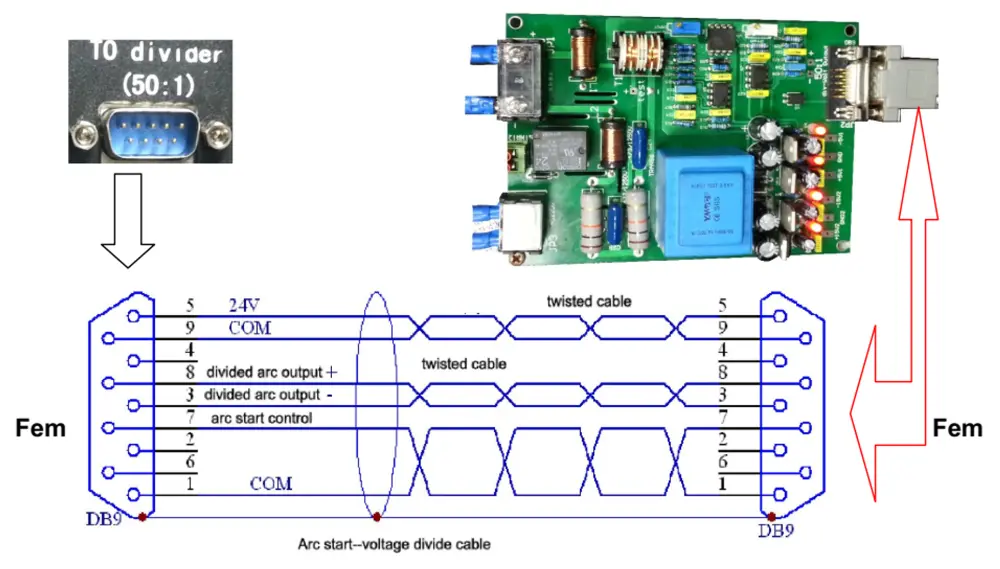

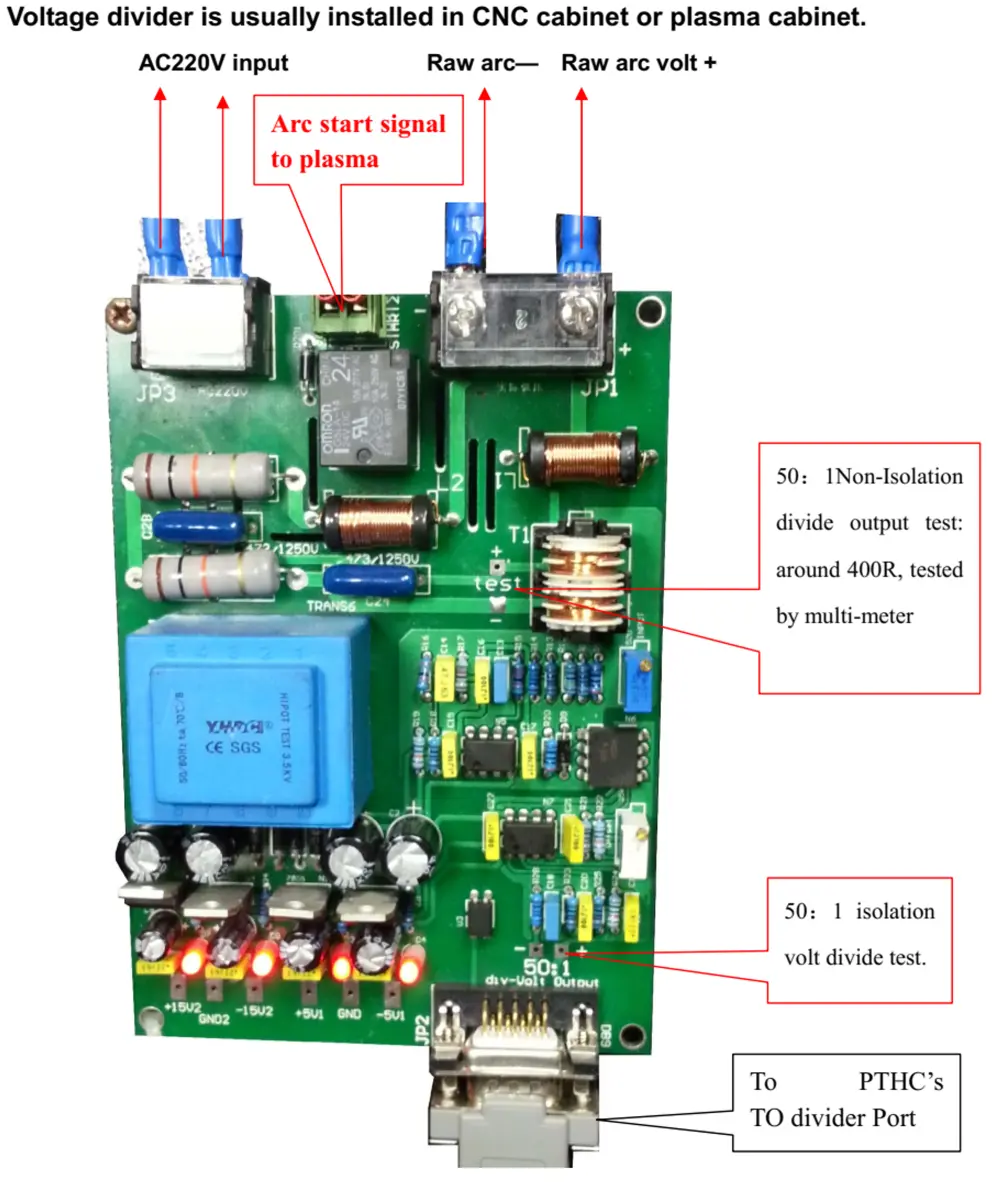

- Voltage Divide ratio: 50:1 non-isolation on voltage divider; 1:1 isolation inside of THC

- Control accuracy :±1V-±3V,depends on the motor and lifter of user.

- The speed of lifting:1000mm/min-3000mm/min(Contact the supplier if it exceeds the range of speed);

- Max speed test:12000mm/min( it's related to the setting on the lifter's speed and motor's start voltage and sensitivity)

Type | Data |

Input Power | AC24V+10%,50Hz/60Hz or DC24V±20% |

Motor | DC24V DC motor |

Output current | 0.1A-1.8A |

Motor Drive | PWM |

Load capacity | Max 20W |

Working temperature | -10-60℃ |

Arc Voltage range | 50V-250V |

Over protection | PWM adjusting, current feedback |

Auto work follows:CNC arc start signal to THC---THC start IHS first----Arc start---THC find divided arcvoltage in THC-------Pierce time delay----Pierce completed---CNC receives arc ok signalfrom THC or Plasma then start Motion----over 90% full speed, CNC enable THC’s automode----Cycle ends and arc off, Torch lift up to programmed height.(Note:there is no dynamic pierce function under sample mode)

Application:

- XPTHC-4H supports almost all plasma cutters on market like Hypertherm, Thermal Dynamics…include HD plasmas like HPR130, 260, Ultra-cut series…

- And it supports all CNC cutting controllers on market like Hypertherm, Burny industrial level controllers or Mach3 such DIY controllers, because XPTHC-4HIII can start Auto Height control with or without Auto enable signal from CNC. But with Auto enable/disable signal from CNC, THC would work better.

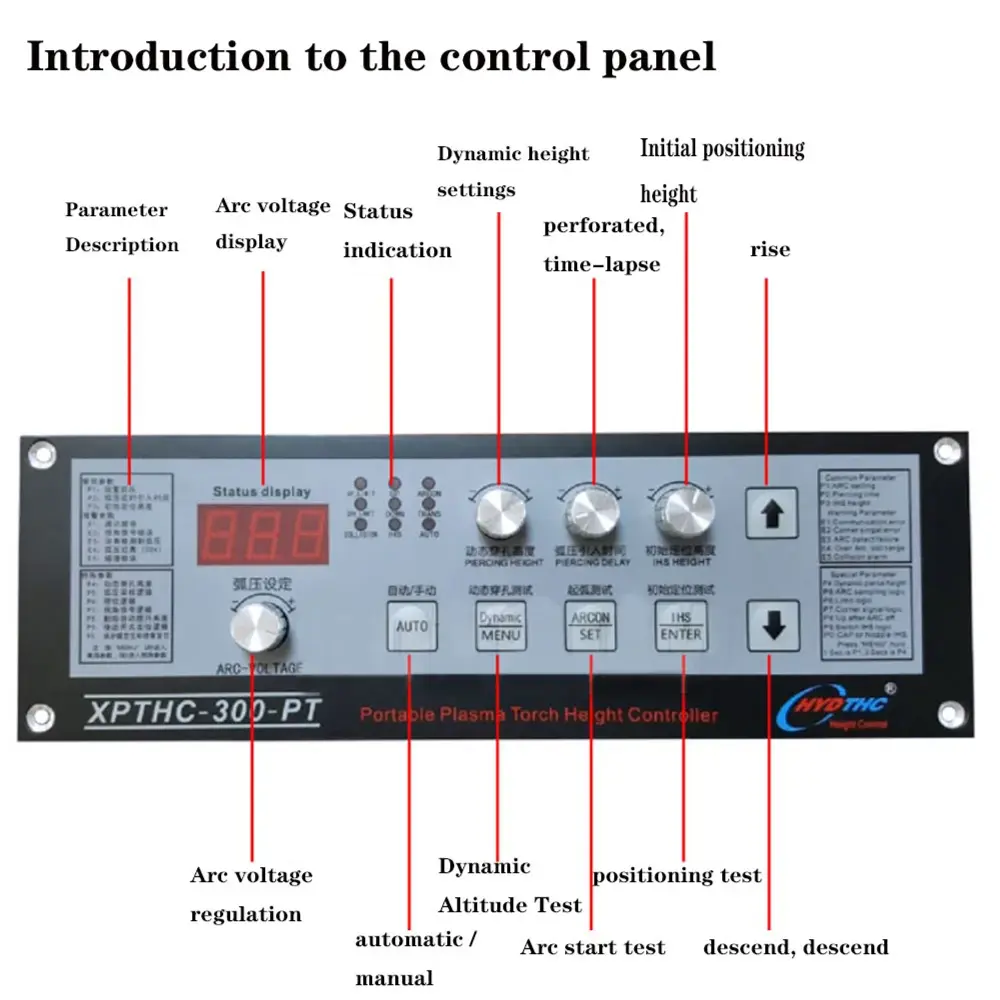

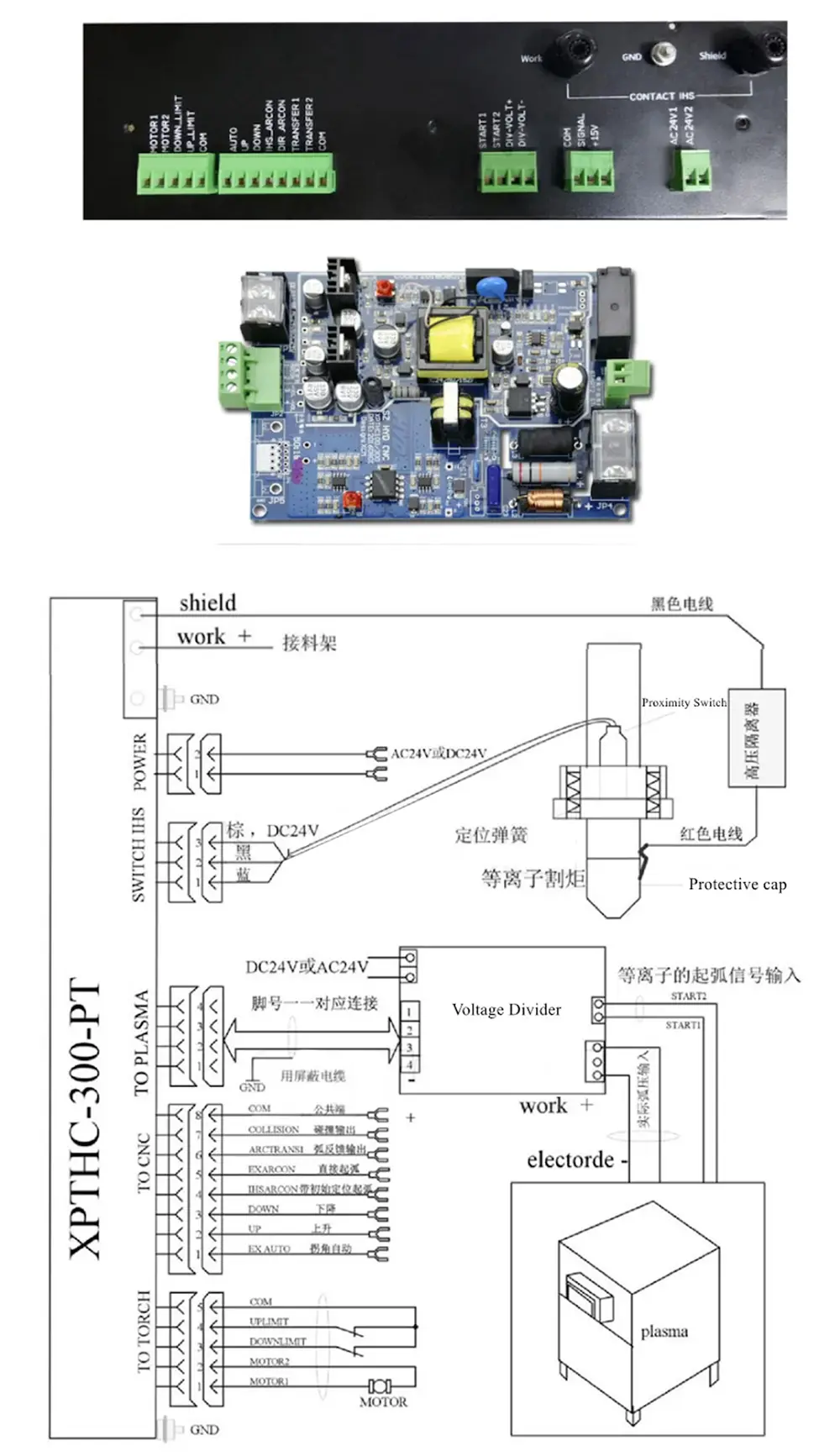

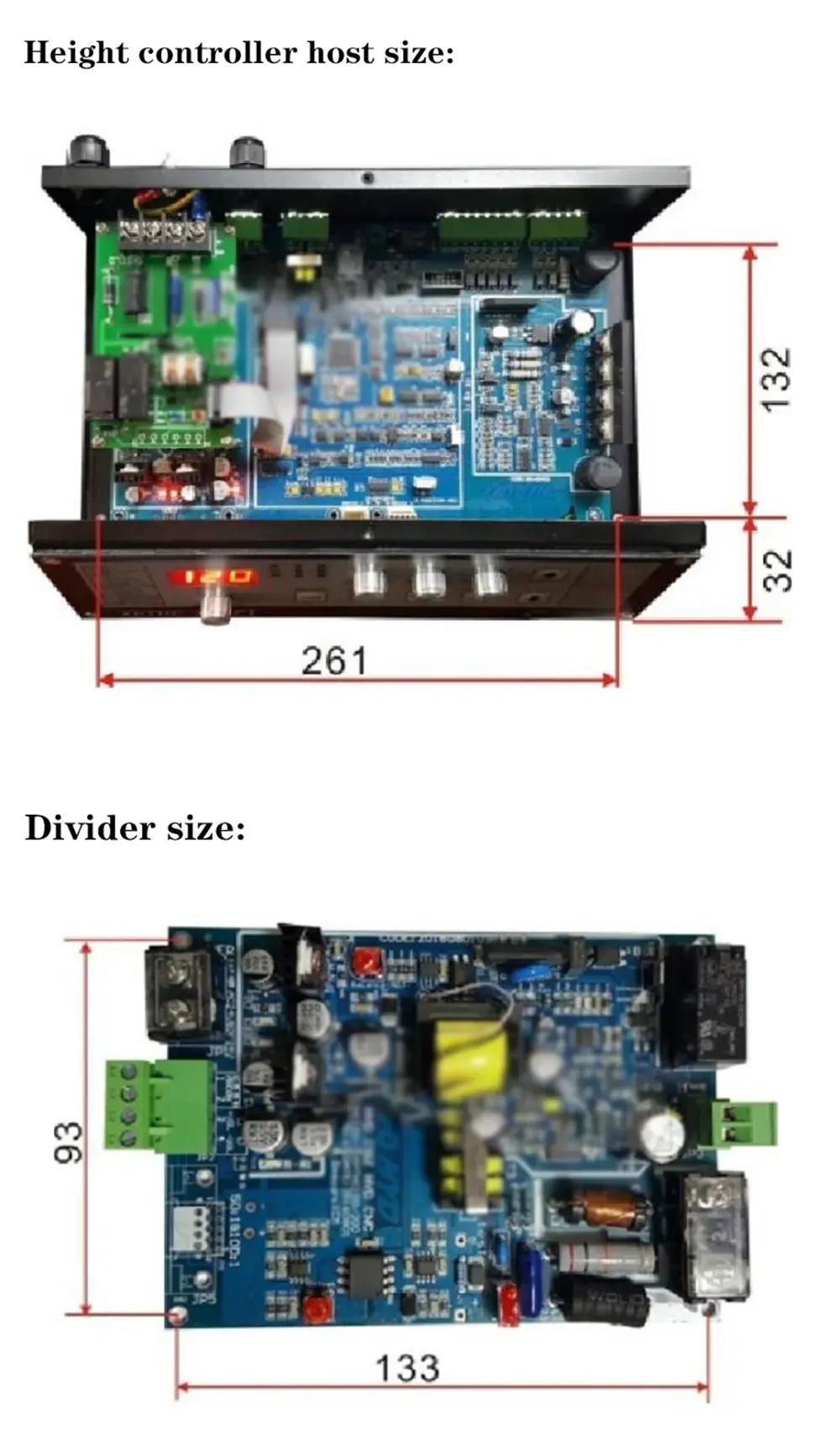

[2]XPTHC-300-PT

Parameter:

- Working power supply: DC20-36V or AC24V ± 10%, 50Hz/60Hz

- Adapter motor: DC24V DC motor

- Drive mode: PWM (pulse width modulation mode)

- Output current: 1A-4A, maximum power 100W

- Working temperature: Height controller -10 ~ 60℃

- Initial positioning method: connect to this switch positioning method & (optional) protective cap contact positioning method

- Operation transmission mode: detect arc voltage enable, pierce complete output.

- Divider ratio: 100:1, it can be changed according to user requirements.

- Control accuracy: The set arc voltage and the actual arc voltage are ±1V ~ ±3V, which are related to the user's lifting mechanism and the starting voltage of the motor.

- Dimensions: length x width x height: 272mm x 225mm x 80mm

- Torch lifting speed: 800mm/min ~ 3000mm/min (please contact the supplier if the speed exceeds this speed)

- Set arc voltage range: 30V ~ 250V, which can be modified according to different applications.

- Overload protection mode: PWM pulse width adjustment, overcurrent protection.

- Maximum cutting tracking test speed: 6000mm/min (related to the user's starting voltage, speed and sensitivity settings of the lifting body)

Safety and installation precautions:

- Before using this product, be sure to read the instruction manual of this height controller carefully to avoid installation or operation errors and cause unnecessary losses.

- Special Note: The power supply voltage of this height controller is AC24V/DC24V power supply.

- Non-professionals or unauthorized persons cannot open the height controller for inspection and maintenance;

- Do not arbitrarily open the adjustable resistor sealed with screw glue to adjust it;

- When not in use, please turn off the power of this height controller in time.

- Do not put liquid on the height controller, so as not to enter the height controller.

- Pay attention to dust prevention, do not let metal dust, etc. enter the height controller.

- When handling, please handle with care to avoid damage.

- The grounding position of the height controller must be well grounded, and the grounding resistance is less than or equal to 1ohm.

- According to the positioning method used, set the correct positioning method of the height controller.

- The ascending and descending directions on the height controller panel must be consistent with the lifter.

- The arc voltage of the plasma must be connected to the voltage divider plate or the voltage divider positioning plate, and the plasma anode cable must be connected to the workpiece.

- The initial positioning operation of the protective cap contact type can be carried out only on the upper side.

- Please do not install the height controller in the place of heat source, the normal working temperature of the height controller is -10℃~60℃. Take appropriate protective measures in environments with high temperature, humidity, dust or corrosive gases.

Package Included:

- 1 x XPTHC-300-PT without/wit Protective Cap Positioning

- 1 x Voltage Divider

- 2 x Filter Rings

- 1 x Proximity Switch (diameter 12mm; NPN normally open close to 2mm)

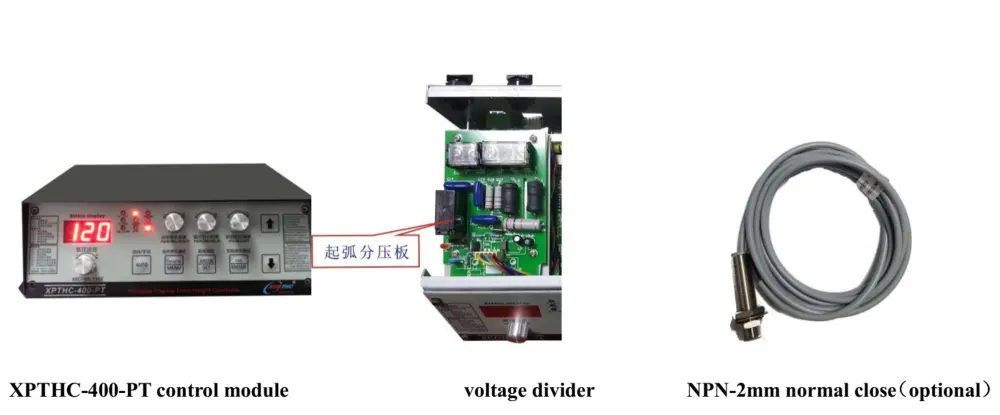

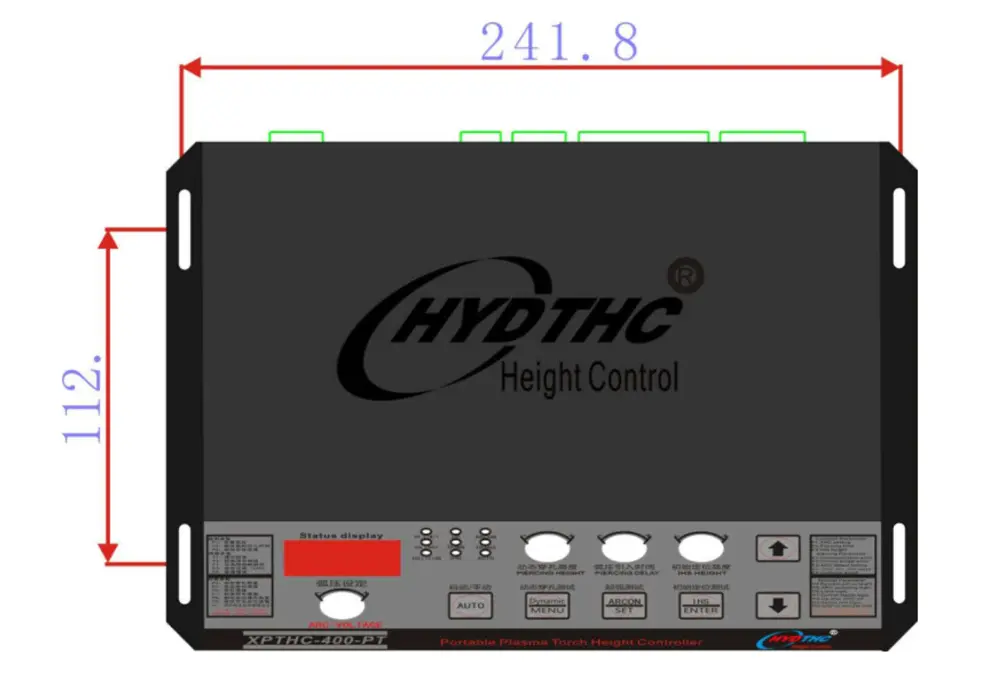

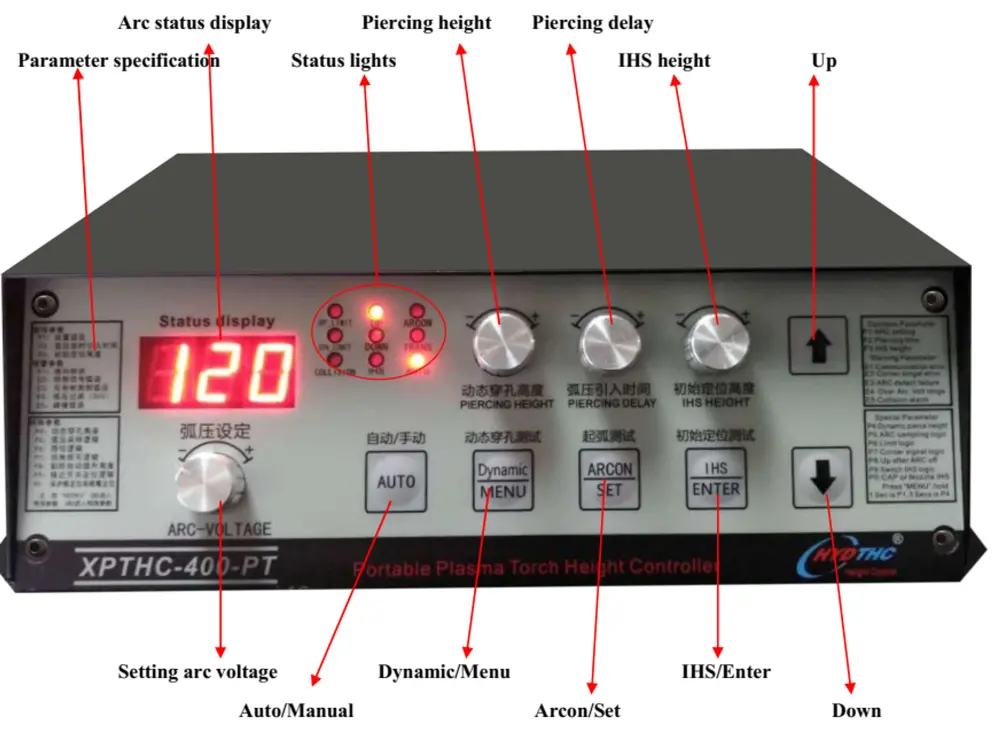

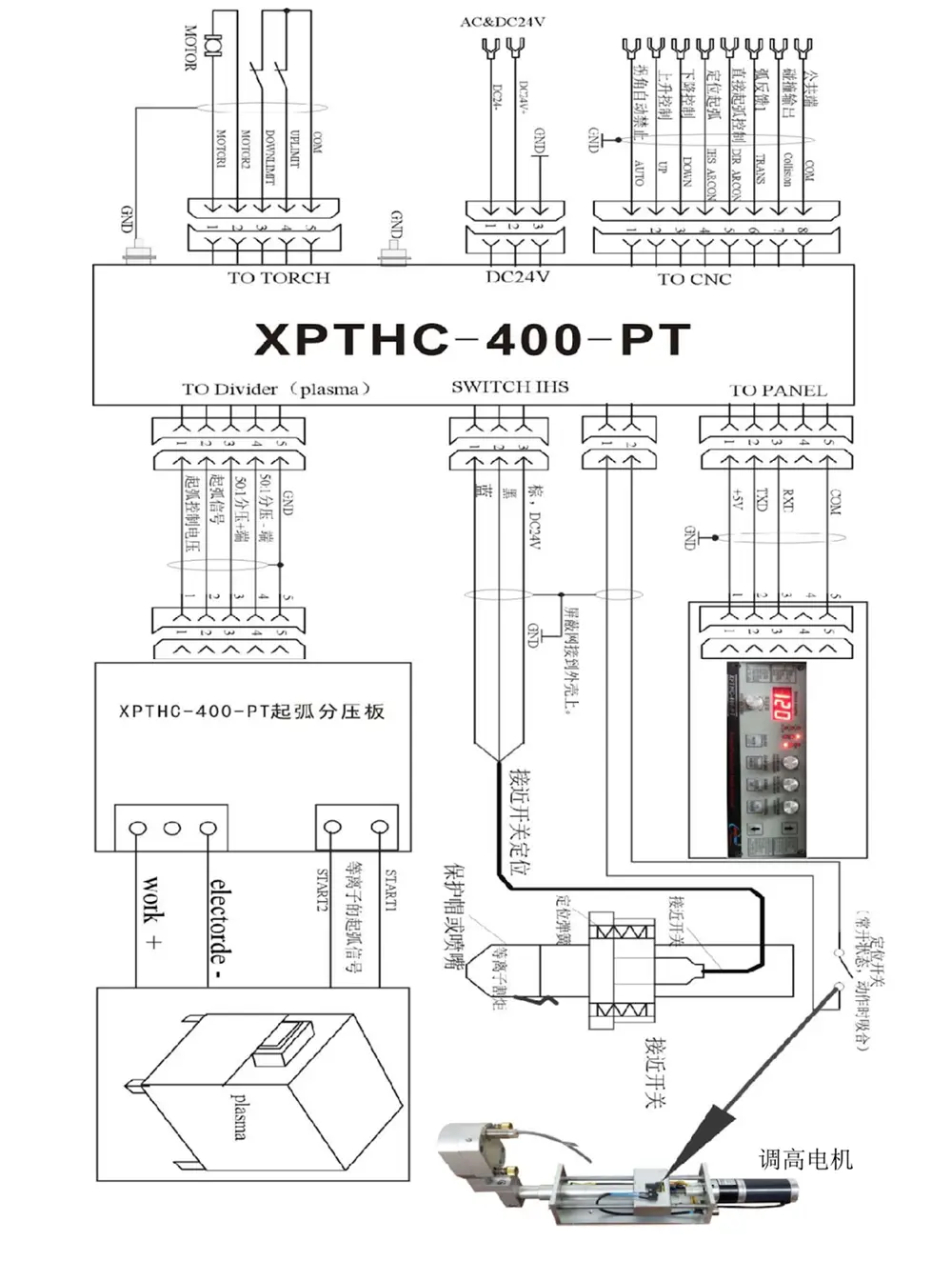

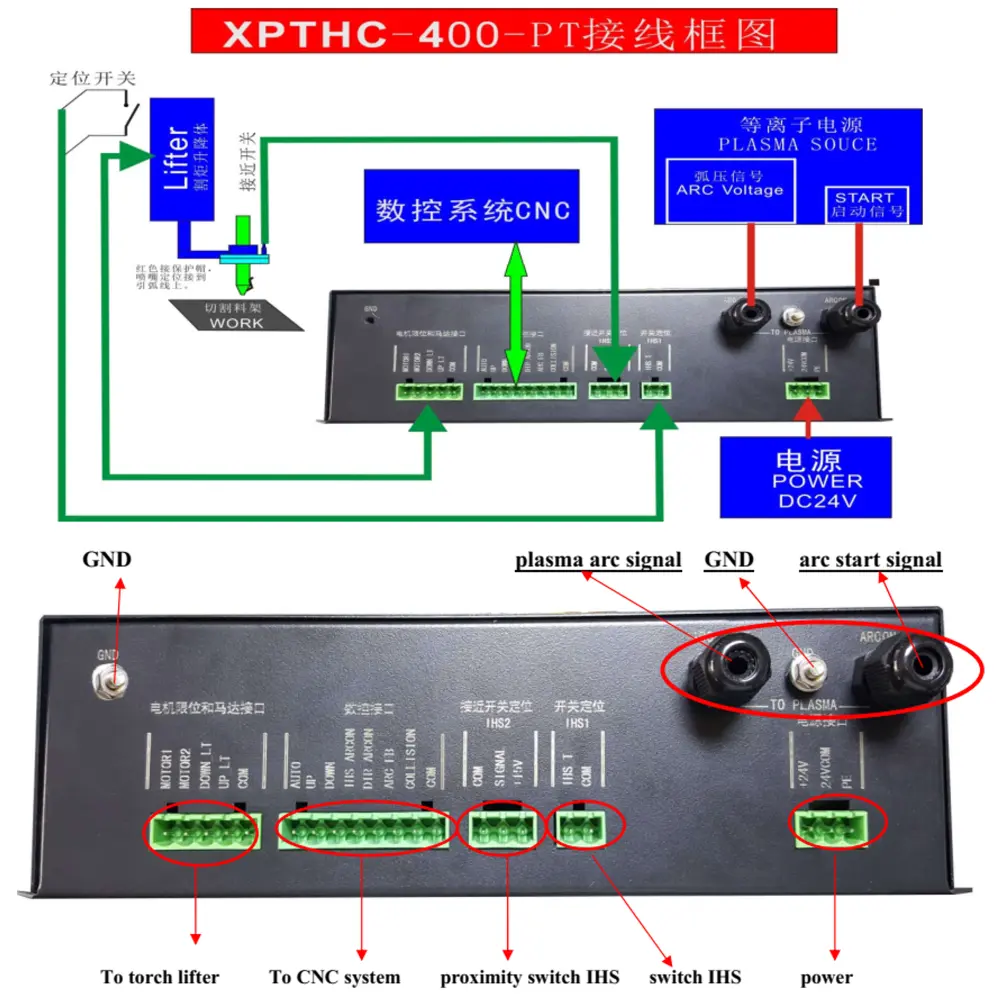

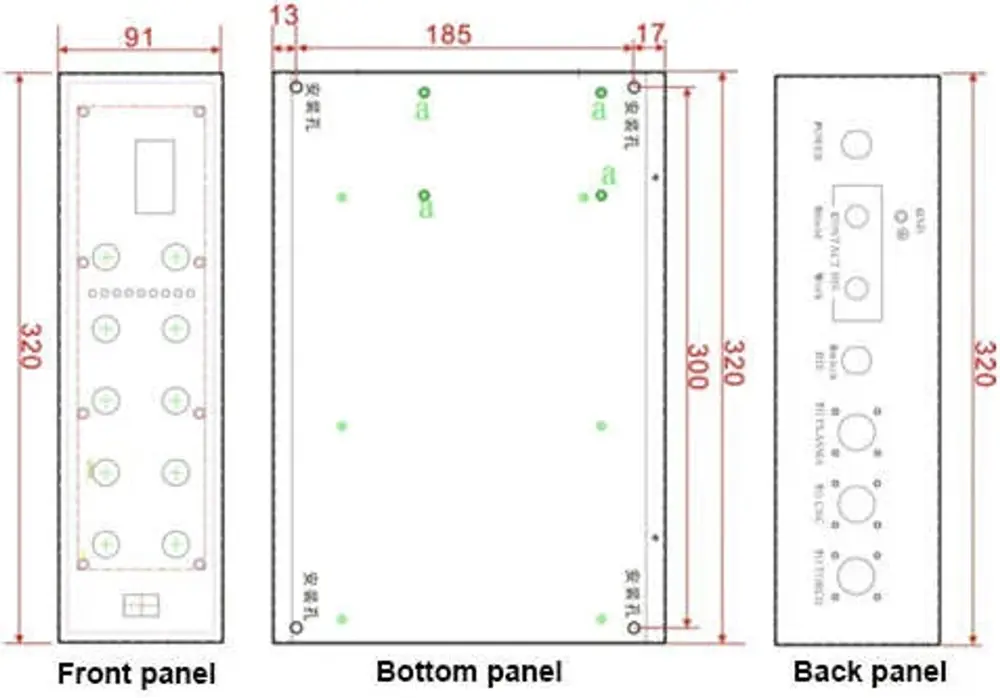

[3]XPTHC-400-PT

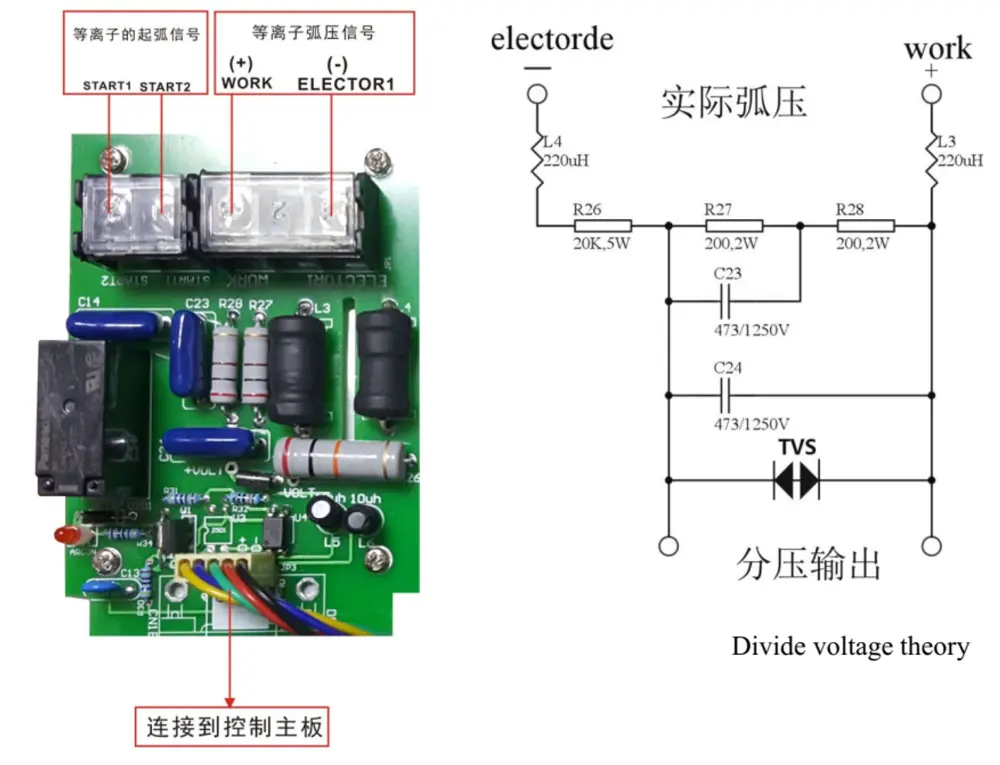

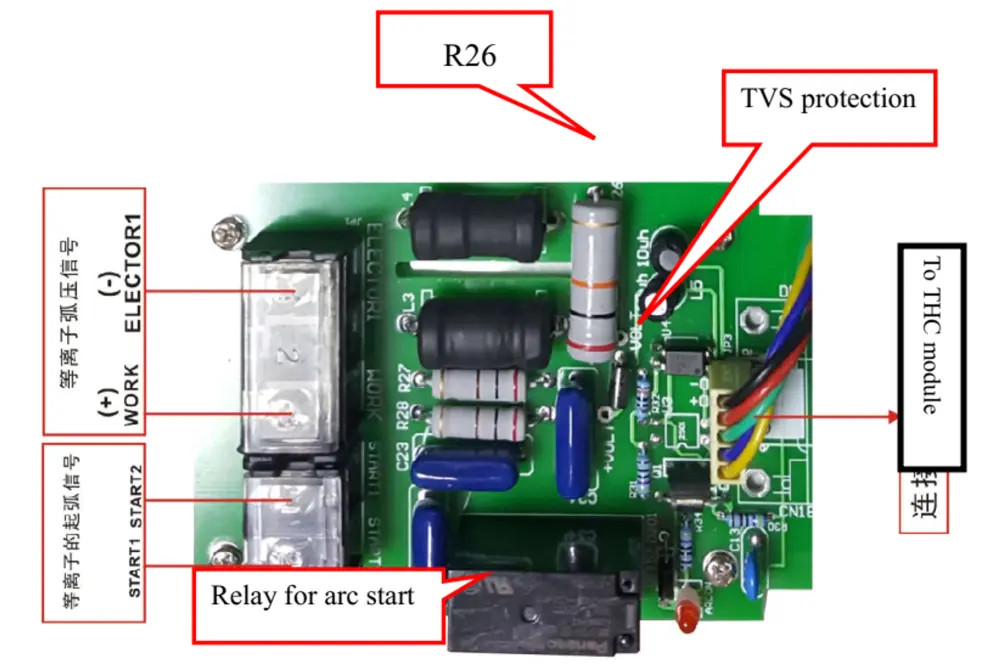

Advantages

- XPTHC-400-PT arc voltage height controller is a cost-effective small arc voltage height controller designed for portable and small gantry cutting machines.

- XPTHC-400-PT uses a high-performance 32-bit ARMCortex-M3 core processor, combined with highly real-time control of analog circuits, to achieve high-speed, high-precision, smooth and stable tracking.

Product technical parameters

Type | Data |

Product model | XPTHC-400-PT |

Power supply | AC24V or DC20-36V |

Working environment | 0-55 ℃ |

Working current | 2A |

Drive method | PWM pulse width modulation |

Drive motor power | DC24V DC motor, maximum power 25W |

Arc voltage setting range | 50V~250V |

Tracking accuracy | ± 1V |

Positioning method | proximity switch positioning |

Basic parameter

- Input power: DC24V10, 50Hz/60Hz.

- Up/Down motor: DC24V DC MOTOR.

- Motor Drive: PWM.

- Output Current: 1A-2.5A,Max capacity: 30W.

- Working temperature: -10∽60℃.

- IHS: Proximity switch IHS & contact switch IHS.

- Run transmission mode: Output the successful signal when the arc voltage is detected.

- Voltage Divide ratio: 50:1.

- Control accuracy: ±1V∽±3V (related to lifter and motor voltage).

- Size: length *width *height: 254mmX171mmX70mm.

- The speed of lifting: 1000mm/min∽4000 mm/min (recommend 2500 mm/min).

- Setting Arc Voltage arrange: 30V∽250V, According to different applications.

- Overload Protection Mode: PWM mode with overload protection.

- Test Max cutting speed : 10000 mm/min (Related to customer’s lifter voltage ,speed and sensitive setting.)

Product Features

- Intelligent judgment of external alarm codes and automatic signal logic

- All membrane buttons and encoder knobs are designed with humanization, comfortable and convenient

- Suitable for proximity switch positioning and switch contact positioning methods

- Built in arc breaking pressure plate, simple wiring and convenient use

- The external interface adopts European style plug-in terminals for external circuit connection, with simple wiring

- Full circuit isolation, high reliability, separate IO isolation, arc voltage sampling isolation, drive isolation, positioning and control isolation

- Dynamic perforation and anti-collision output function effectively protect the lifespan of vulnerable parts and cutting torch

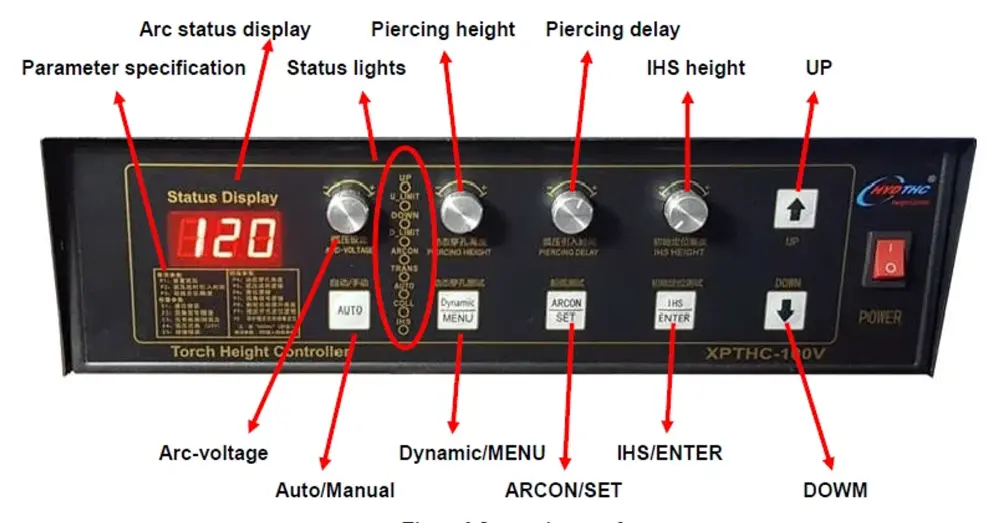

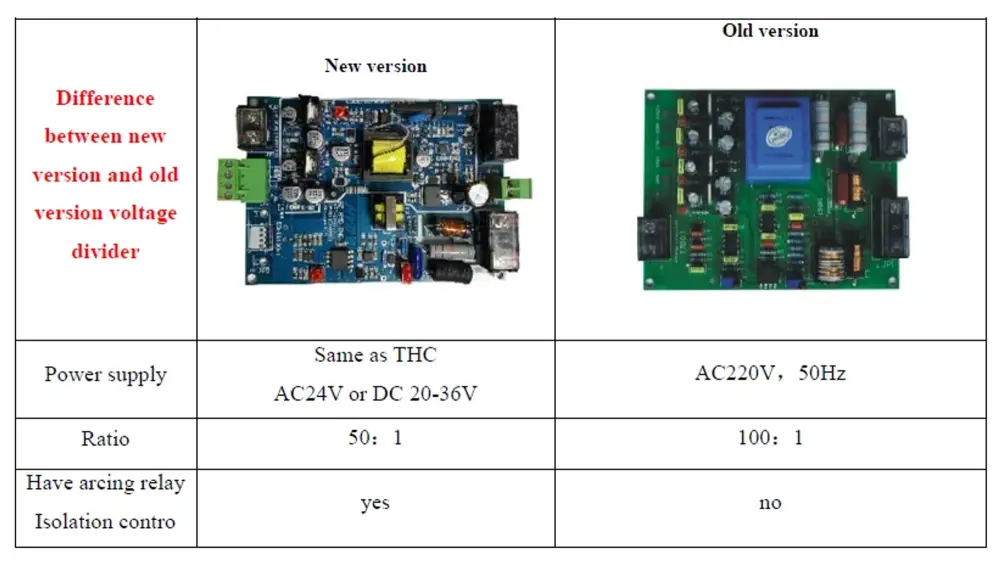

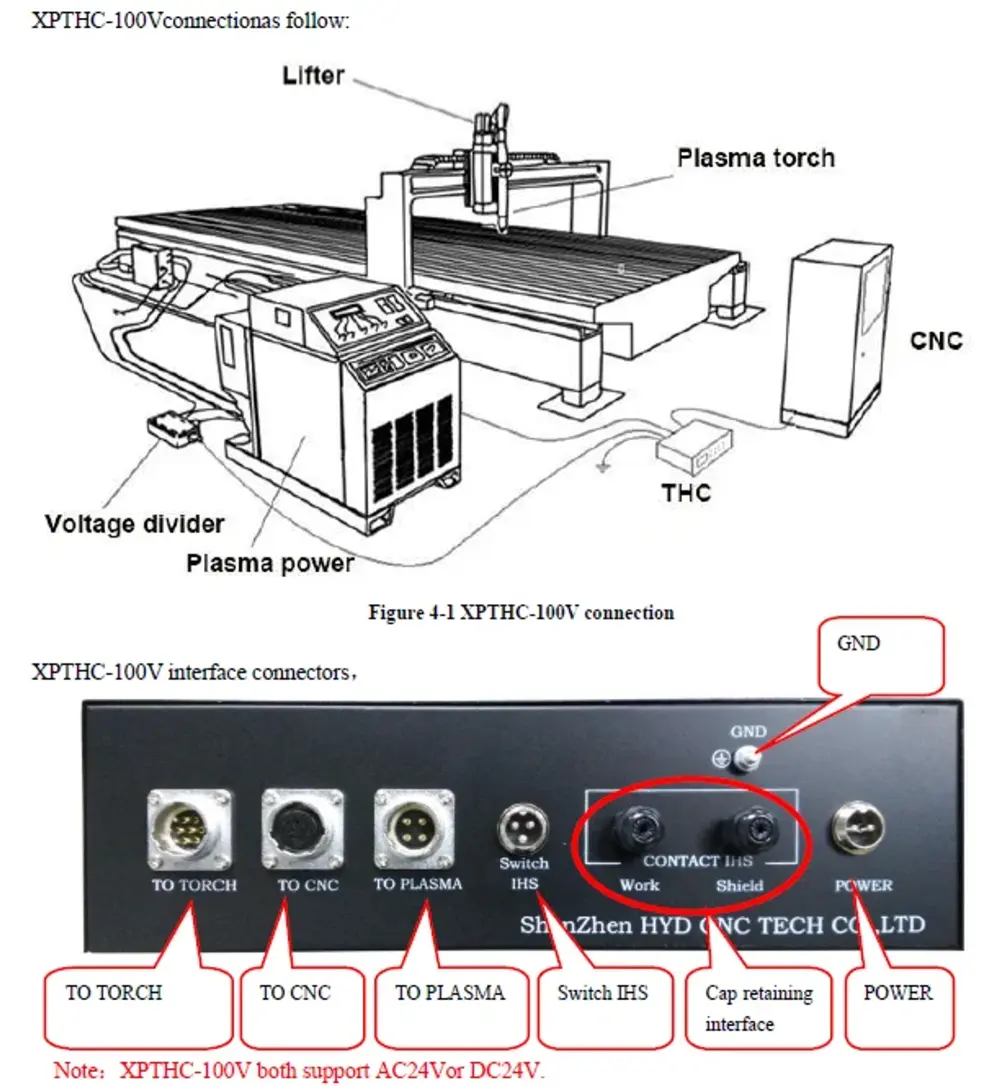

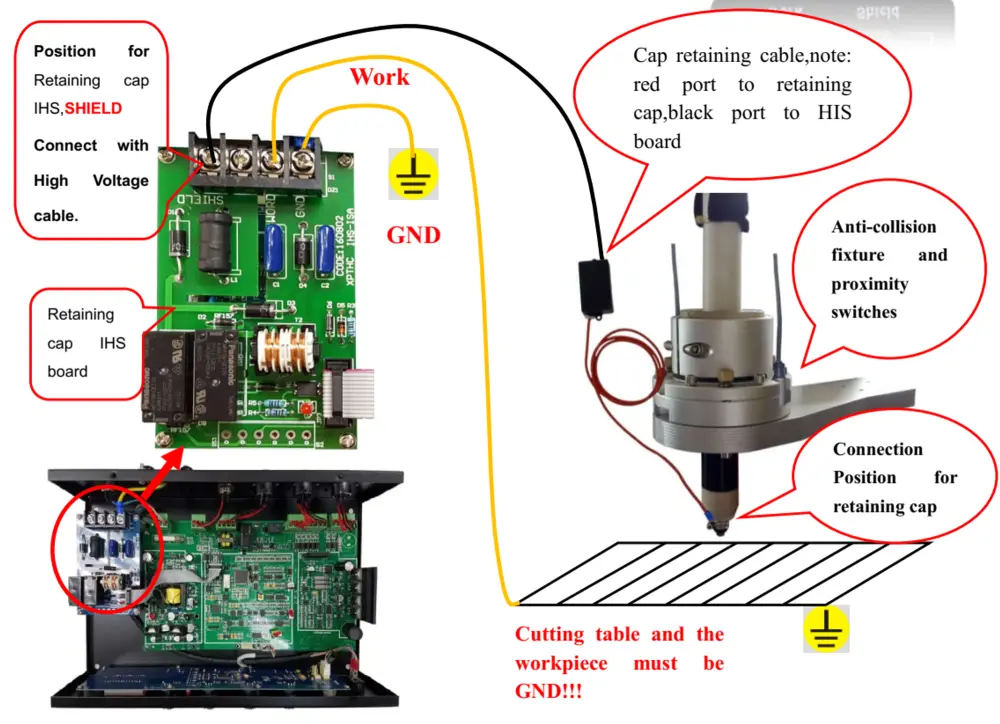

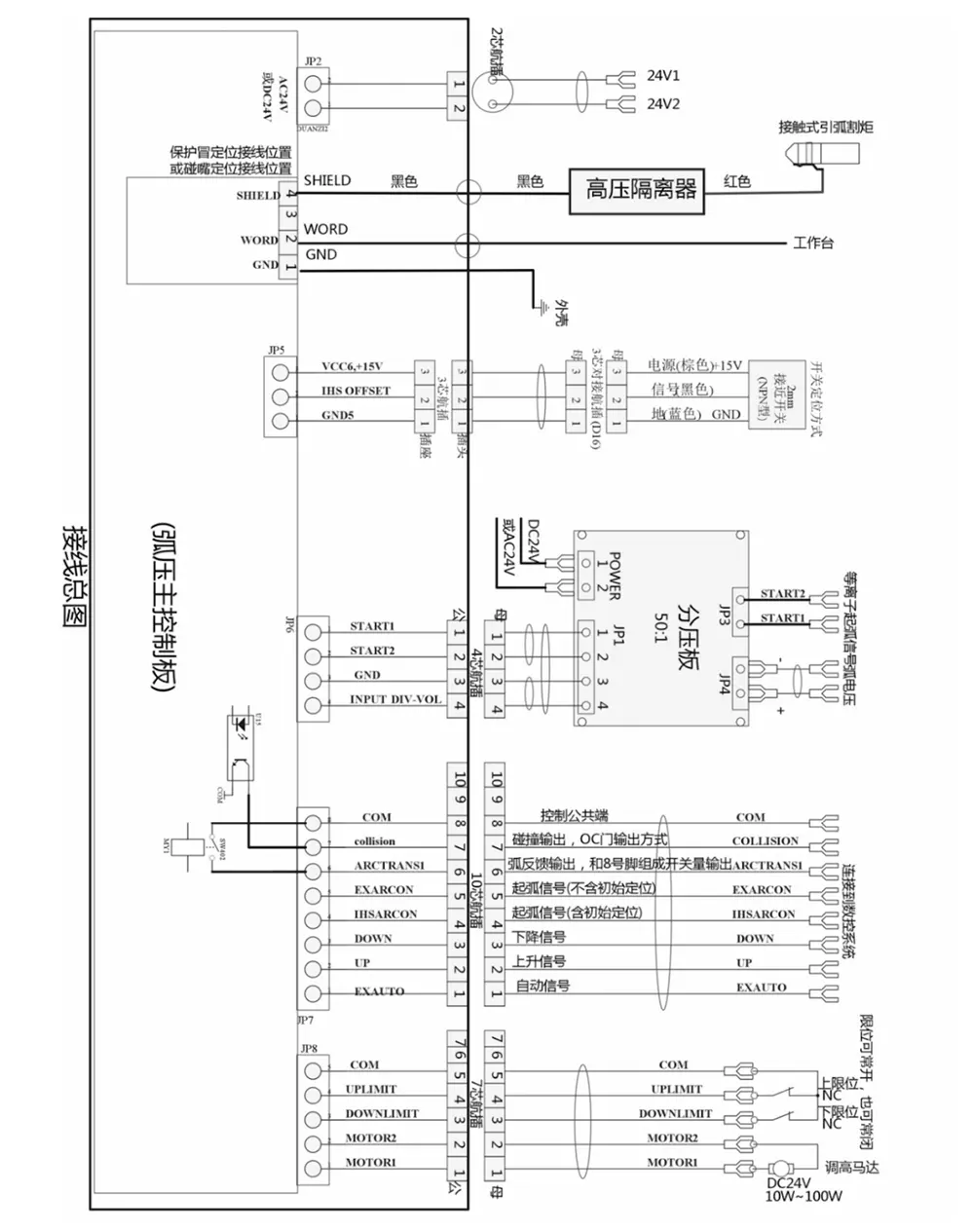

[4]XPTHC-100V

Basic parameter

- Input Power:DC24-36 or AC24V+10%,50Hz/60H z

- Down/Up Motor:DC24V DC MOTOR

- Motor Drive: PWM ;

- Output Current:1A-4A, Load capacity:100W,

- Working temperature:-10∽60℃

- Voltage Divider ratio:50:1

- Control accuracy:±1V∽±2V

- Size :length width height:272mm225mm80mm

- The speed of lifting:1000mm/min∽4000mm/min(Contact the supplier if it exceeds the range of speed)

Application

- XPTHC-100V supports almost all plasma cutters on the market like Hypertherm, Thermal Dynamics…include HD plasmas like HPR130, 260, Ultra-cute series….

- And it supports all CNC cutting controllers on market like Hypertherm, Burny industrial level controllers or Mach3 such DIY controllers because XPTHC-100III can start Auto Height control with or without Auto enable signal from CNC. But with Auto enable/disable signal from CNC, THC would work better.

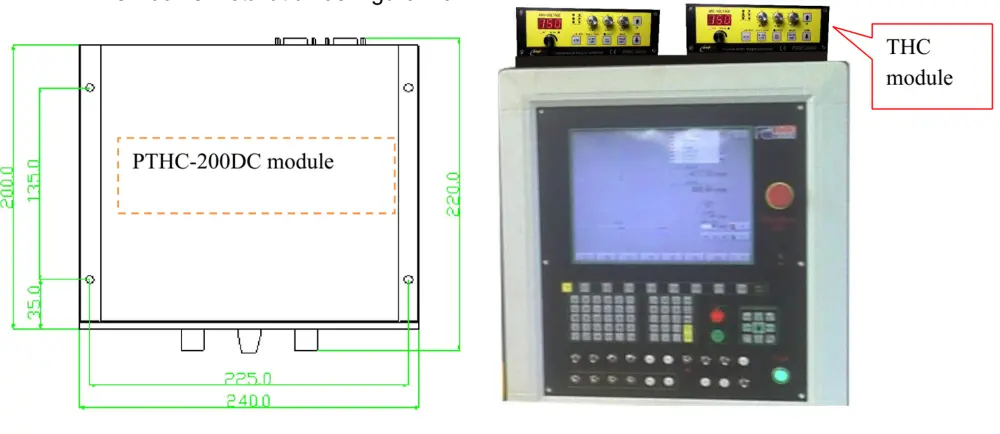

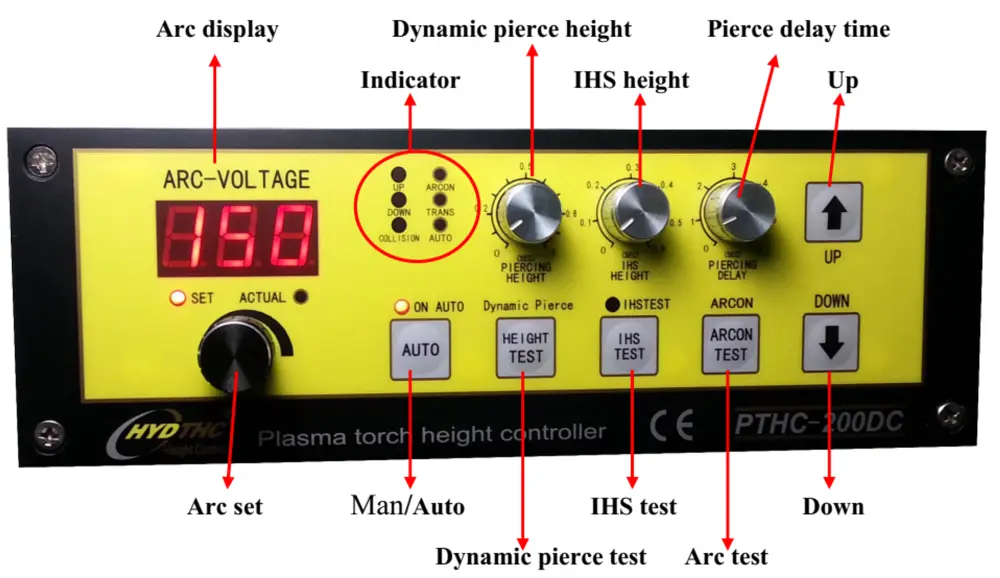

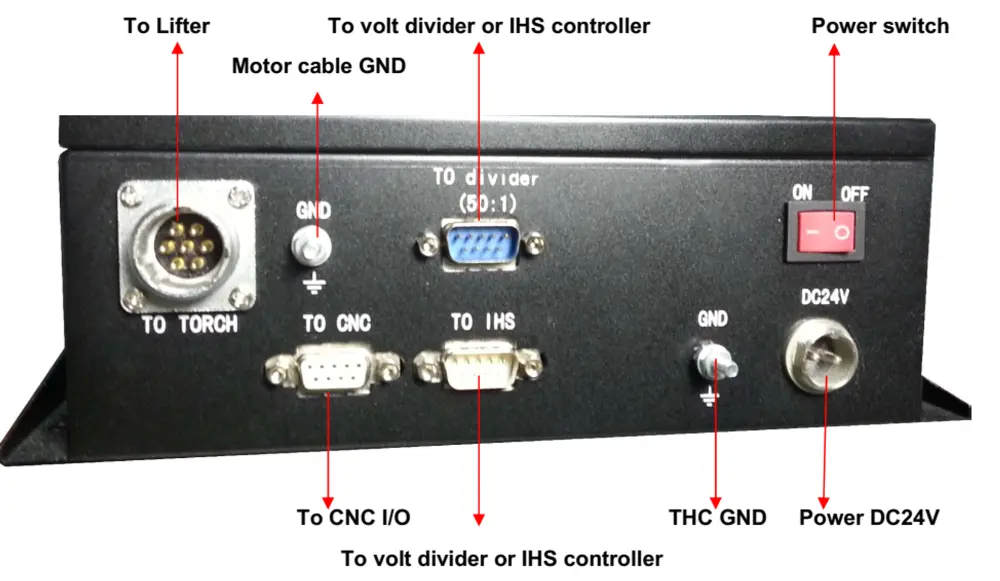

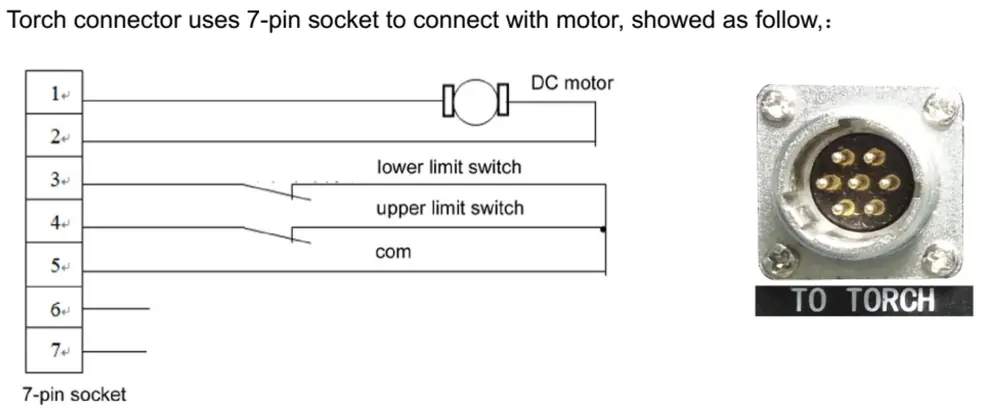

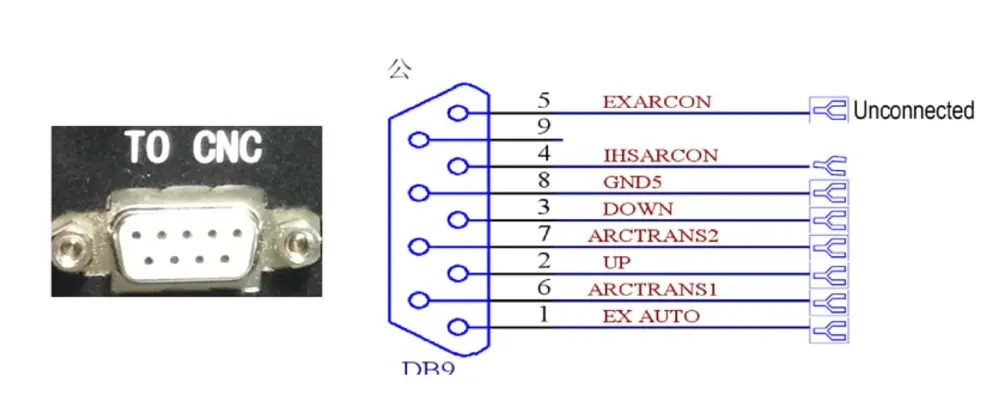

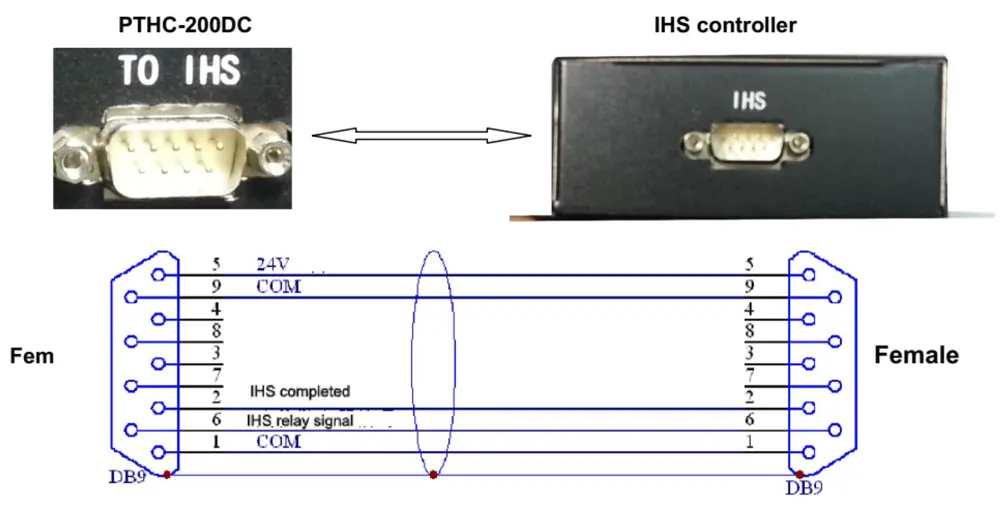

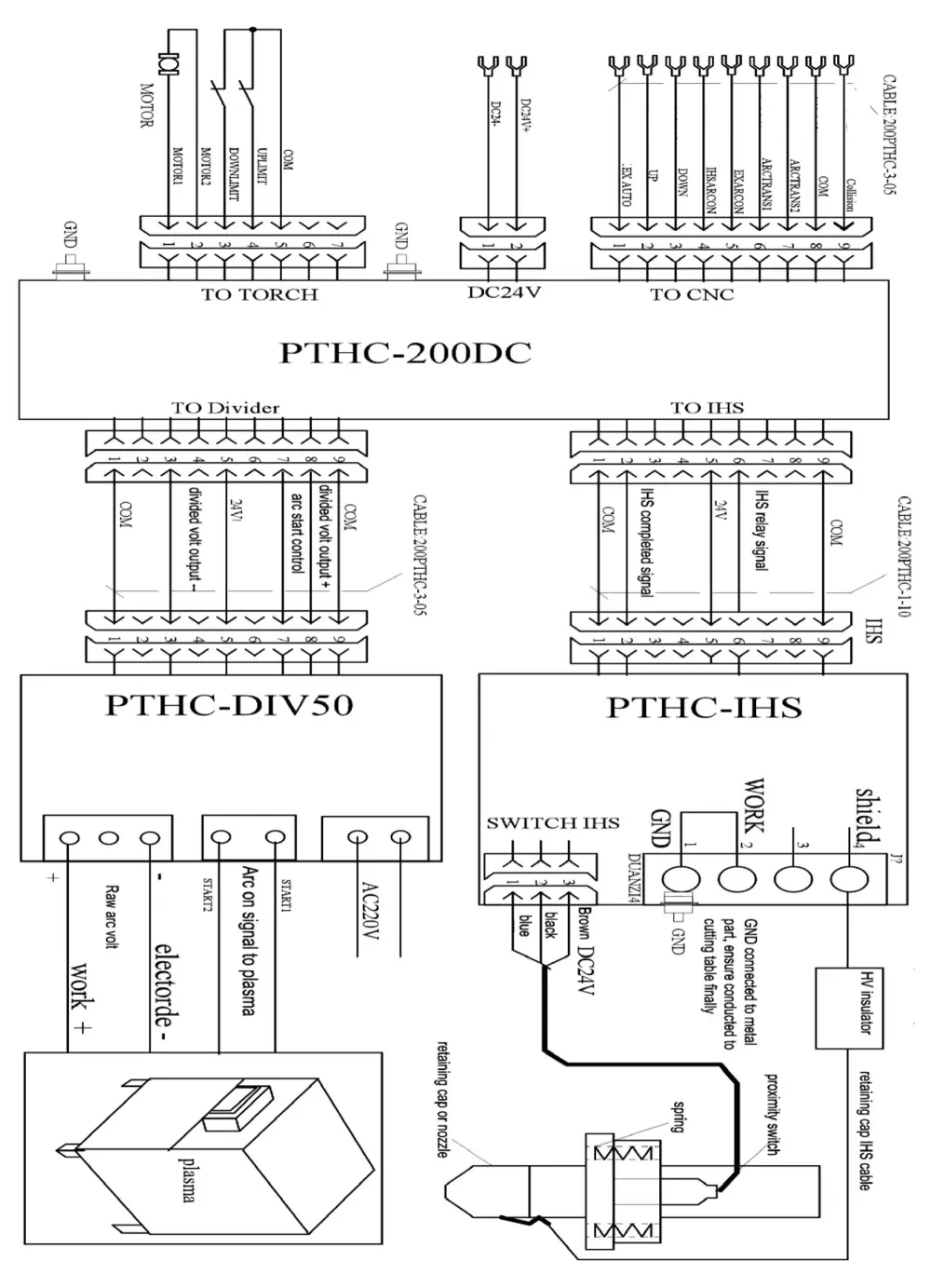

[5]PTHC-200DC

IntroductionPTHC-200DC is designed to support almost all plasma cutters on market, with full industrial Torch height control functions. It automatically controls plasma cutting height by monitoring the plasma’s arc voltage change during cutting

Specification

- Powersupply:AC24V+10%,50Hz/60Hz 或 DC24V,18V~30V;

- Support Motor:DC24V motor;

- Drive mode: PWM;

- Output current:1A-4A;

- Output Watt:100W;

- Work temperature: -10∽60℃;

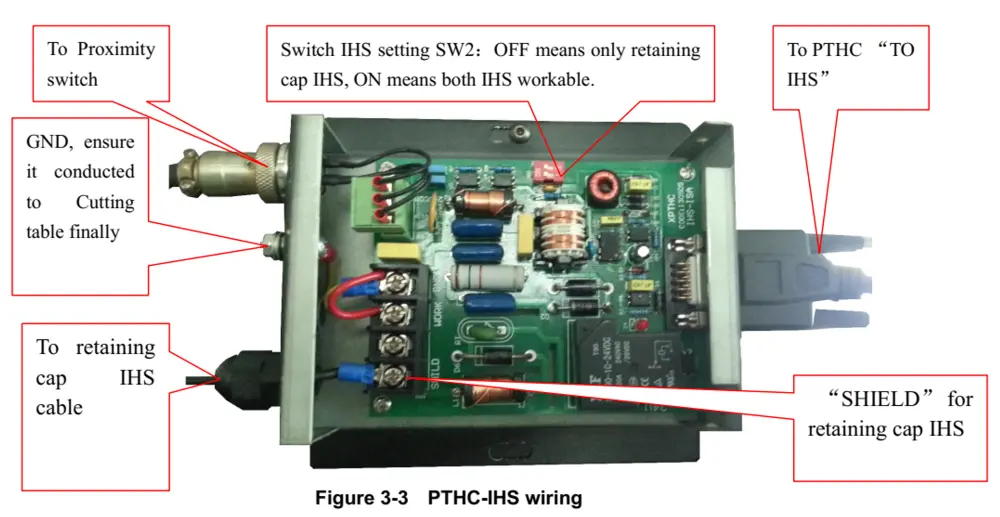

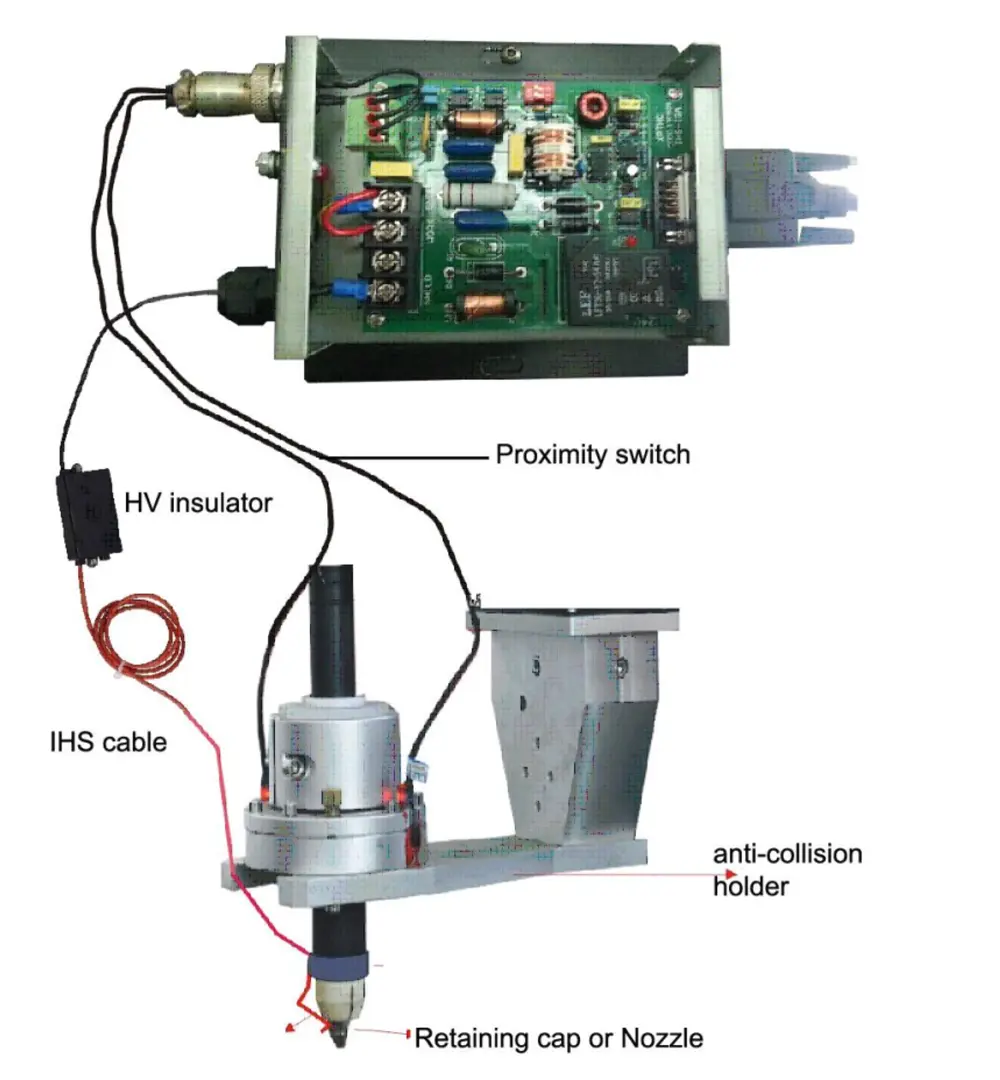

- Initial sense mode:Proximity switch IHS & Torch retaining cap IHS;

- Voltage divide ratio:50:1;

- Accuracy:±1V∽±2V,

- Lifter speed:1m/min ∽ 4 m/min(over 4m/min,please contact supplier);

- Set arc voltage range:35V∽250V,adjustable;

- Support Max cutting speed :12000mm/min

Key features

- Auto Initial Height Sensing(IHS) Torch Retaining Cap IHS( ohmic contact) and Proximity Switch IHS are both available, Proximity Switch IHS is for cutting dirty/rusty workpiece, needing the Anti-Collision Fixture designed by HYD (breakaway kit ). It supports underwater cutting too.

- Anti-Collision Function When the torch tip touches the workpiece, THC automatically lifts the torch to IHS height to avoid crashing. It is effective both in Manual/Auto mode.

- Freeze Auto Height Control on Corner Signal XPTHC-300 would freeze Auto Mode on receiving corner signal from the CNC system to avoid torch diving on Cycle start/end, corner turning.

- Support DC/AC24V power supply both

- Dual speed during IHS, better torch tip protection, and 6 indicators for easy trouble-shooting. When it gets a problem, we can easily find the problem by the indicator's on/off state and make a fast solution to the customer.

- THC sensitivity, torch retract height after cutting....many functions adjustable to the user.

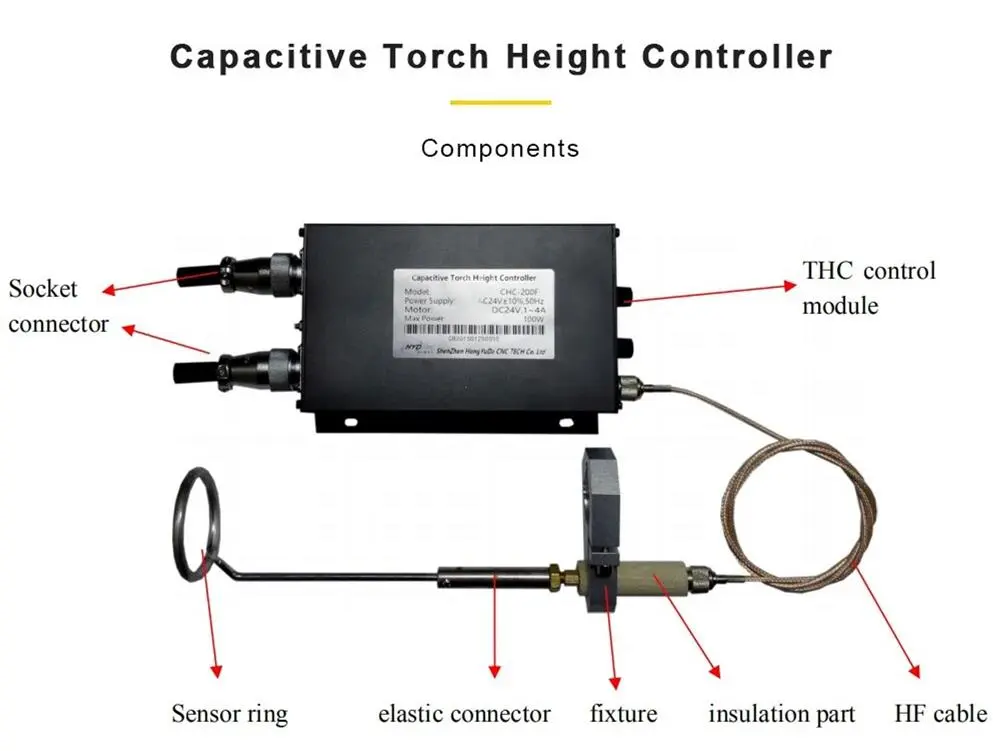

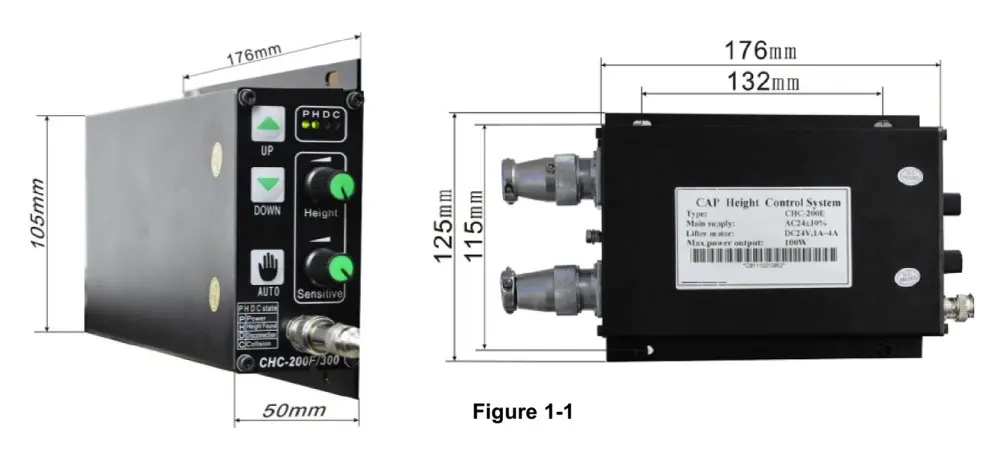

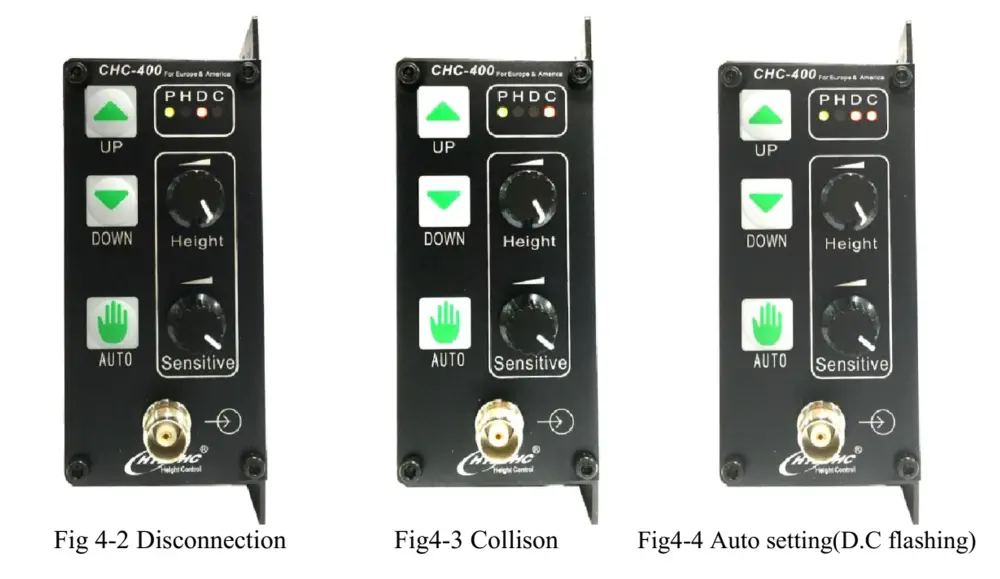

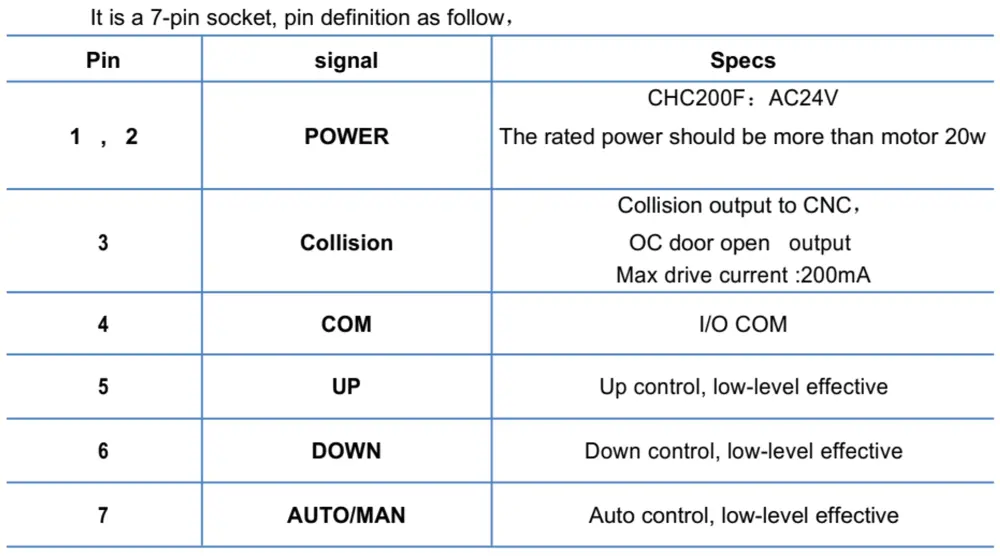

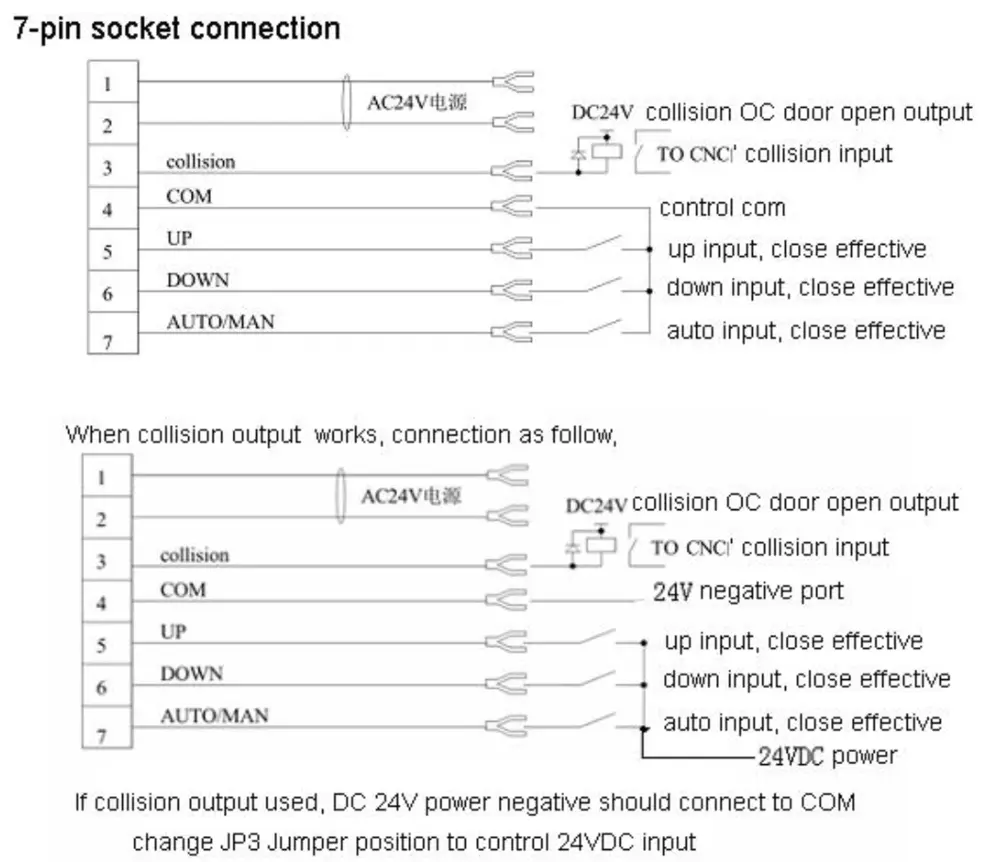

[6]CHC-200F

Instructions

- The CHC-200F capacitor height adjuster is a newly designed product that uses a high-performance 32-bit Cortex-M3 core ARM processor, combined with analog closed-loop circuits, and combines the characteristics of real-time height control of the old CHC-200E height adjuster.

- It innovatively achieves automatic recognition and calibration of the induction probe, and better practical functions such as collision prevention, wire breakage protection, and manual dual speed control.

Basic specification

- Power supply: CHC-200F: AC24V±10%, 50Hz/60Hz;

- DC motor used on lifter: CHC-200F: DC24V (From THC to DC motor);

- Output current: CHC-200F: 1A-4A, max: 100W;

- Work temperature: THC-10∽60℃; HF cable: -10∽ 200℃;

- Sensor parts: -10∽ 350℃。

- Accuracy: ±0.1mm (matters with lifter design);

- Auto height range: from cutting material surface 1mm — 25mm.

- HF-cable:200mm∽ 1800mm。

- Product size shows as figure 1-1 LWH: 176mm * 105mm * 50mm

New featuresComparing to CHC-200E, CHC-200F has new features as follow:

- Increase more indicators to show different states of THC.

- Output of collision-alarm, which is optical isolation output from THC, can be sent to CNC’s Alarm input to freeze the machine's move. This signal is effective in both manual/auto mode. The max output is 200mA, capable of driving most relays.

- Anti-collision function. On manual/auto mode, when metal or low-conductive item like hand touches sensor ring, THC would send out collision signal and lift torch up until no collision exist.

- When HF cable is disconnected or weakly connected, it would be indicated on the disconnection indicator. So after installation of HF cable, just shake the HF cable, the connection will be shown by the indicator.

- Sensitivity and Accuracy has increased 100%.

- CHC200F uses digital logic control circuit for logic control, greatly improved anti interference performance.

Product features

- New generation patented product with automatic gain control and PWM stepless speed regulation, achieving high-speed, high-precision, smooth and stable tracking

- Dual speed mode, when manually adjusting, jog low speed and long press high speed

- Probe induction automatic recognition and one click calibration, convenient to use, without the need for tedious debugging, reducing debugging time.

- Automatic detection and collision prevention, wire breakage protection function, following in place signal output

- Power indication, white dynamic balance point arrival indication, high-frequency cable disconnection indication, probe collision indication

- Thin film operation panel, dustproof and waterproof, knob adjustment, simple and fast

- Aluminum alloy shell, metal shielding and anti-interference, stable and easy to handle for heat dissipation, beautiful appearance, and easy installation

📄HEAVTH THC controller

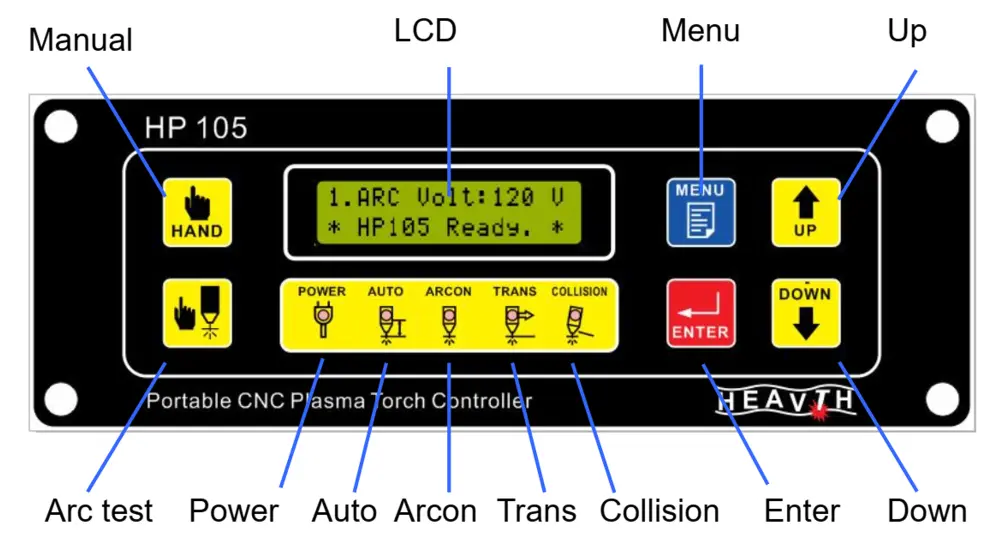

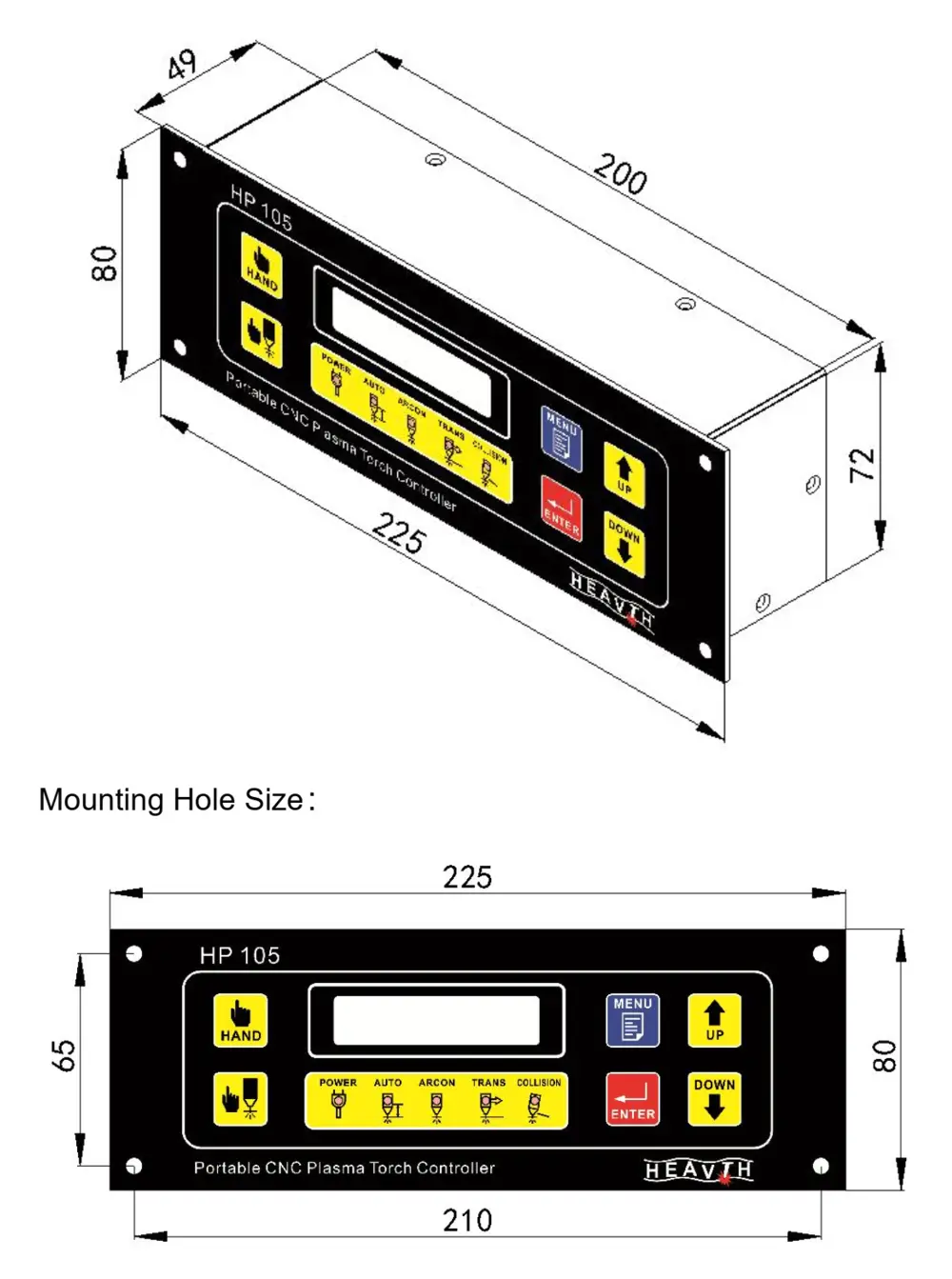

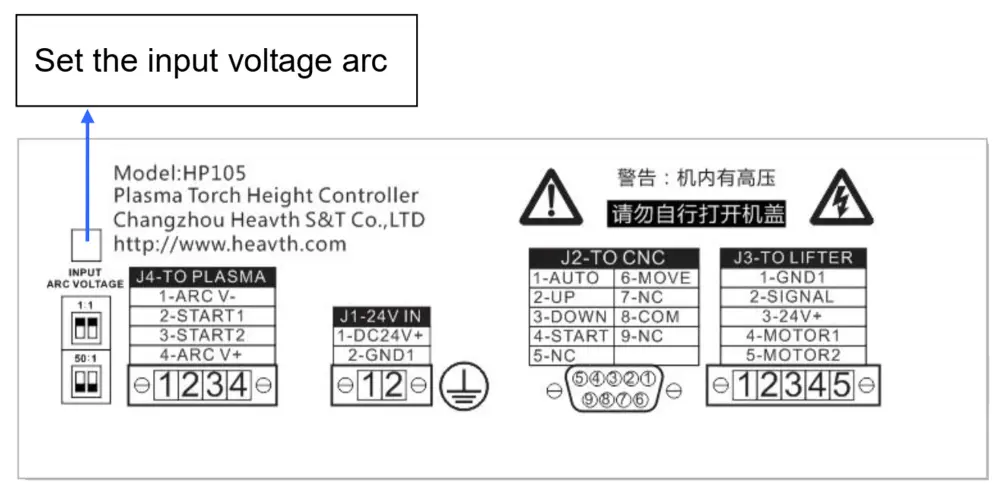

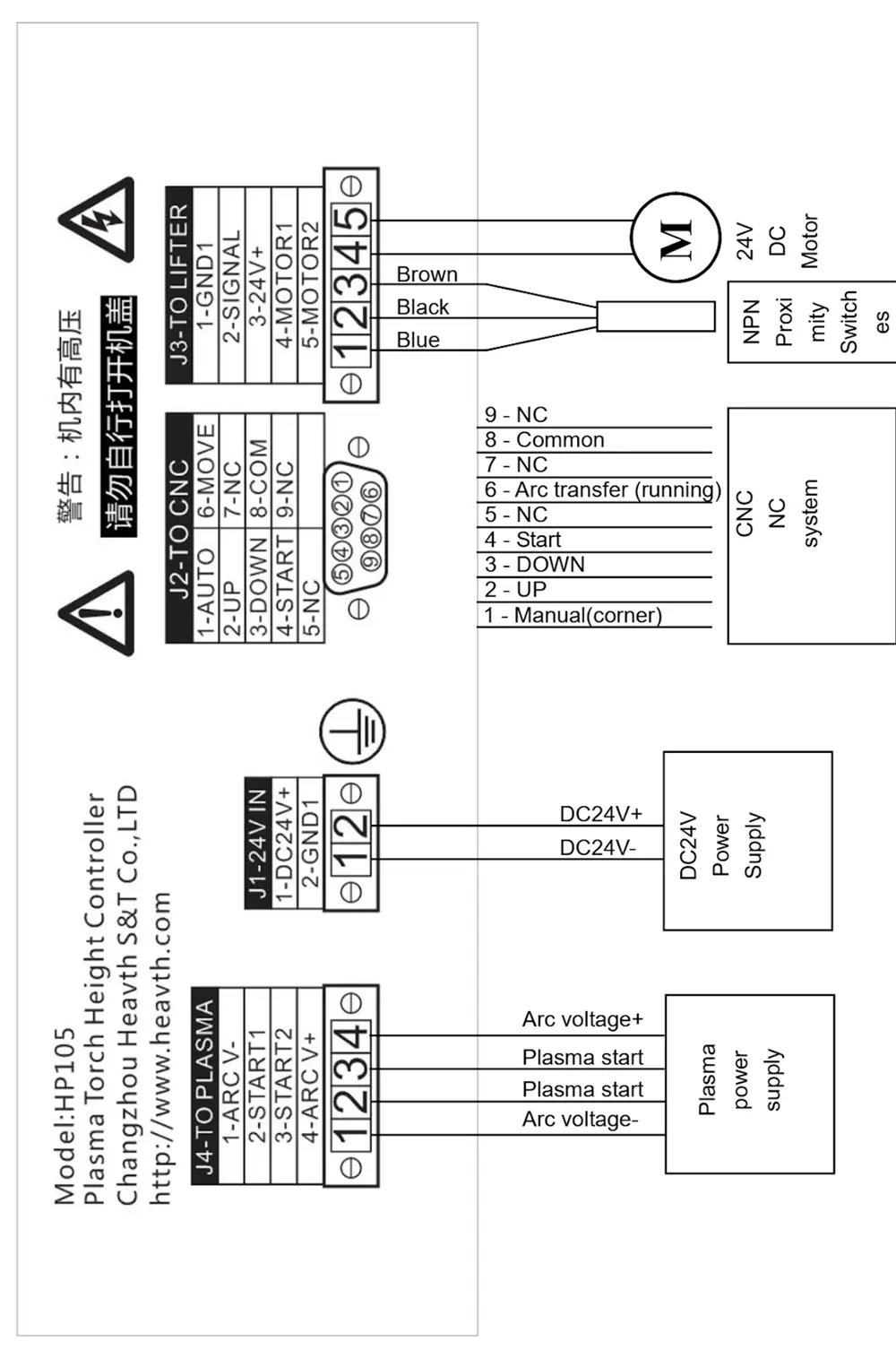

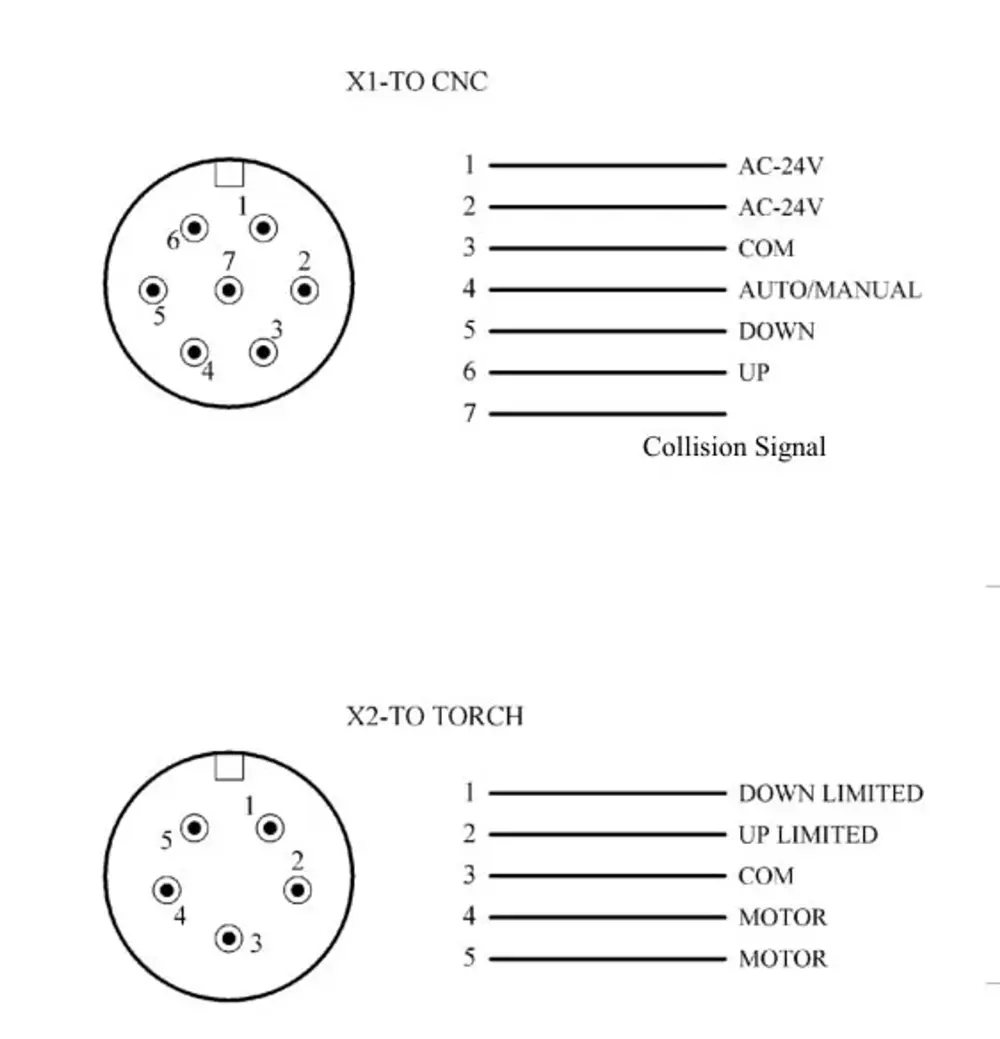

[1]HP105

Description:

- HP105 plasma arc voltage height controller is equipped with constant current plasma. During cutting courses, the current always equals the given current. And the cutting arc voltage will be changed with the fixed speed being the height of torch changing.

- When the distance gets farther,the arc voltage increases; On the opposite, the arc voltage will decrease. HP105 plasma arc voltage height controller will inspect the voltage change, then control the distance between cutting torch and material via the lift motor. So that the arc voltage is fixed, the same is the height of cutting torch. Generally, the instruction will list all the cutting parameters for some type of plasma.

- The user can refer to these parameters. Adjust the voltage in the arc voltage height controller to match the selected current. The torch height will keep constant under regular speed. In fact, the user should set the arc voltage according to the height of the cutting torch. In the status of automation, the arc voltage higher,then the height of the cutting torch higher.

Specification:

- Working Voltage: DC24±10%,50Hz/60Hz, Please prepare a isolated power, do not shared with others such as electronic valve. Especial Pay more attention the DC 24V

- Lift motor: DC24V DC motor

- Drive mode: PWM

- Output current:1A-2A.

- Working temperature: Height controller -10∽60℃

- IHS style: Switch inspecting IHS (suitable for all plasma both above-water and under-water cutting)

- Running transfer: Alternative Arc transfer and pierce transfer

- Input arc voltage:1:1 or 50:1

- Accuracy: ±1V∽±5V,adjustable

- Outer Dimension: Length, Width, Height: 225mmX50mmX80mm

- Weight: 0.8kg

- Protection class: IP64, to prevent dust from entering.

- Installation connector: 2-pin, 4-pin, 5-pin, DB-9 core

- Installation position: Keep away from heat, air convection good place

Function Description:

- LCD: Display the working status and parameters.

- Manual: Auto / Manual mode selection.

- Arc test: Arc test key is used for testing the plasma arc on.

- Menu: In standby mode press to enter the parameter setting mode.

- When the parameter setting, Press to return to standby.

- Enter: Parameter setting mode, confirm that the set parameters.

- Up/Down: In standby mode, manual lifting torch.

- When parameter setting, Increase or decrease parameter values.

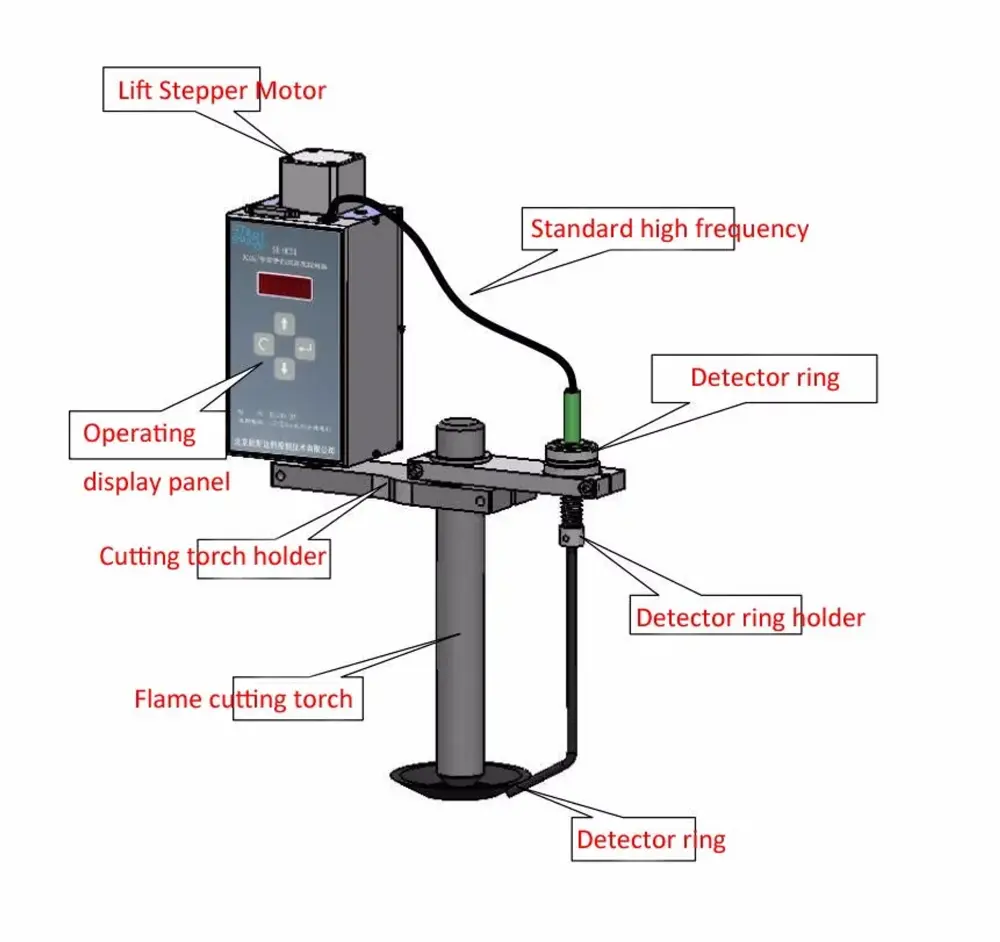

[2]HF100

Quick Detailproper configuration of the torch lifter mechanism is an important factor for establishing the accuracy of your cutting system,be sure that:

- gear reduction is selected on the torch lifter so that the maximum suspension speed does not exceed 3000mm/min,if higher accuracy is required,maximum suspension speed should be set to 1500mm/min

- gears, racks and spindles have minimal backlash

- oversizing is avoided.the mass of moving parts,including armature inertia must as small as possible.motors with low nominal RPM are preferred

- only DC motors with the following ratings are used:

motor ratings: DC MOTORmotor voltage: DC24Vmax current: 6A

Pre-installation considerations

- check to confirm that you have all of the required parts

- familiarize yourself with the parts of the HF100

- check to be sure that the torch lifter motors you are using with the HF100 are within the acceptable range

- review the instructions for configuring the lifter mechanics in section 1.6 of manual

Applications:

- Designed for CNC flame cutting machine

- High induction sensitivity, run smooth and stable

- Set upper and lower limit switches inside, reduce the loss of motor, prolong the service life.

- Used for cutting torch auto height control of cutting machines, it is suitable for the vast majority of imported or domestic models of machine.

Technical Data

- Main supply: AC24V ±10%,50/60Hz,100W

- Current: Max 6A

- Lifter Motor: DC24V , the maximum permanent-magnet DC machine for 4A

- Working temperature: control box:-10℃~60℃ ,HF cable:-55℃~200℃

- Sensor Distance: 5mm-20mm , adjustable

- Accuracy:±0.1mm

- Length of HF Cable: 1000mm

- Sensor Type: Ring

- Sensor Dimension: outer diameter 80mm, inner diameter 40mm

- Housing Dimension:180mm100mm65mm

- Weight: Control box 0.9kg

- Control box with sensor components 1.3kg

Maintenance Skills:

- Install the torch height controller correctly.

- Replace the consumables in time before completely damaging them.

- Avoid the collision of the torch height controller.

- Keep the connection threads clean.

- Check if there are loose parts.

Competitive Advantage:

- Professional manufacturer of CNC Cutting Machine Accessories

- More than 16 years experience

- Factory direct price and on time delivery

- Secure Ordering and worldwide delivery

- Sample available 6. Small quantity acceptable

- OEM workable

Specification:

Type | Data |

length X width X high | 155*105*85mm |

Working voltage | AC24V±10% 50Hz/60Hz |

Drive Mode | PWM (Pulse Width Modulation) |

Lifting motor | DC 24V motor |

Output current | 1A~4A, Max 6A |

Output power | 100W |

Working temperature | —10~60 |

📄STAR(StatAi) THC controller

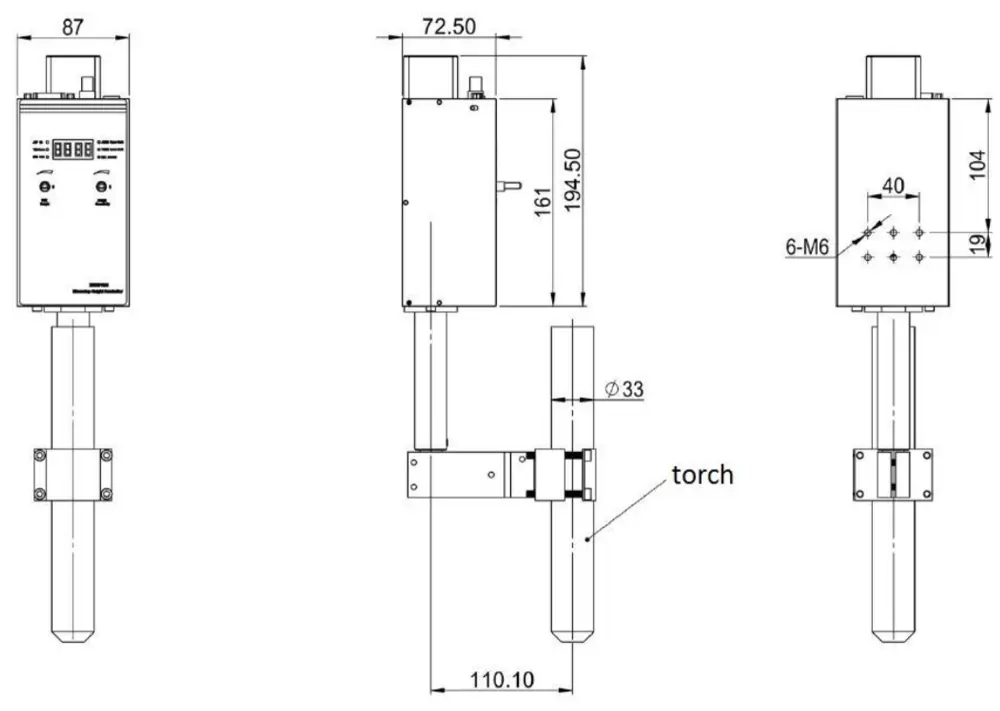

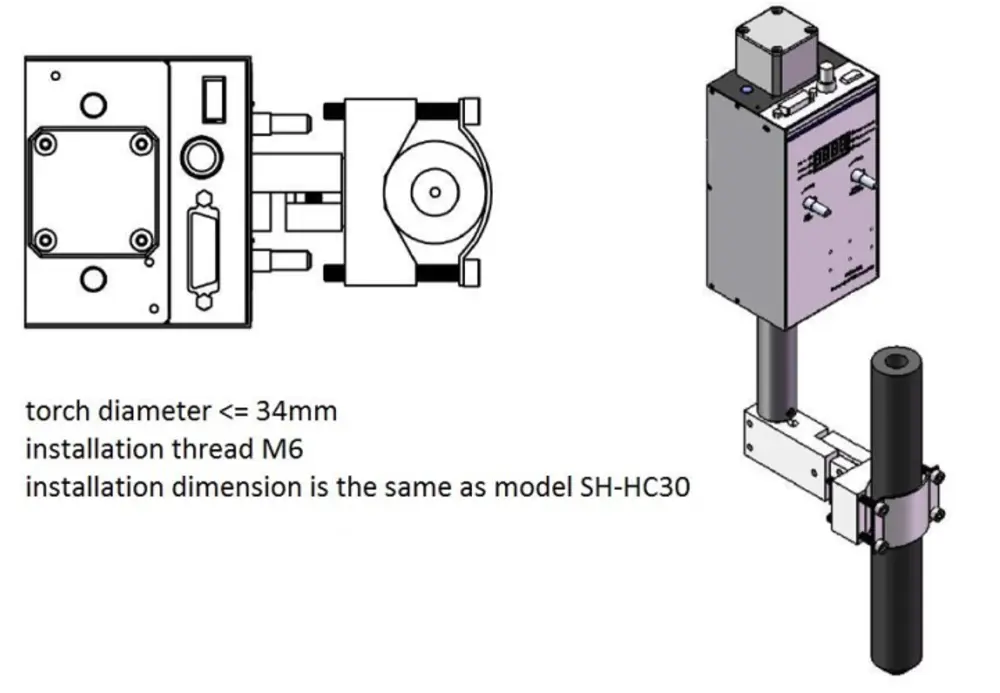

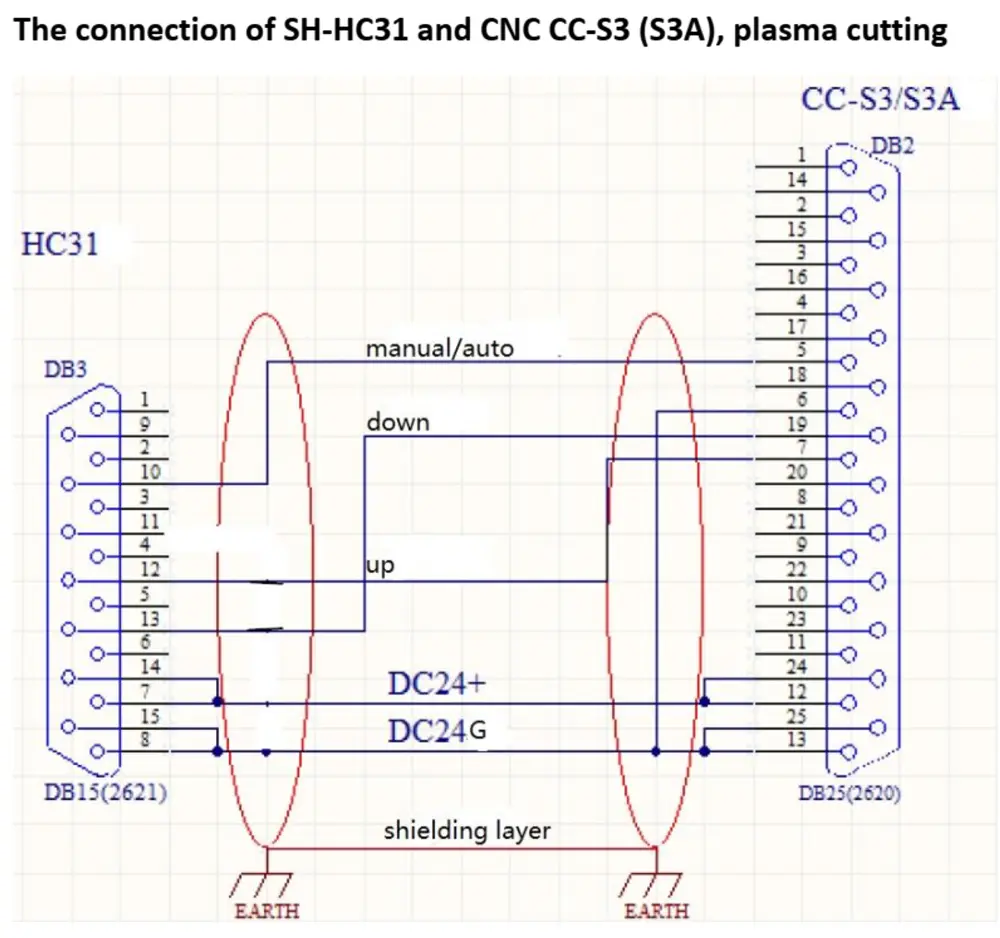

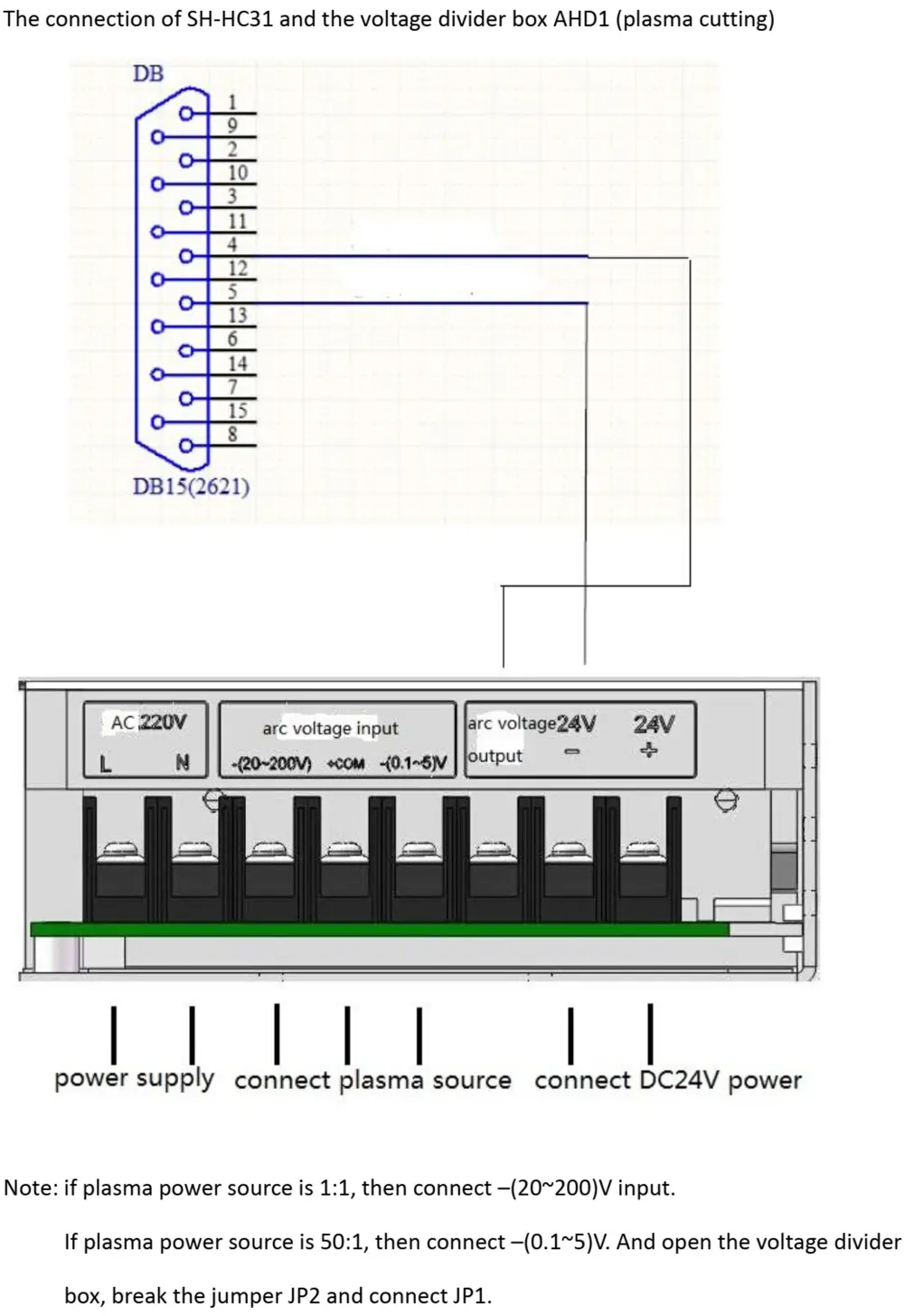

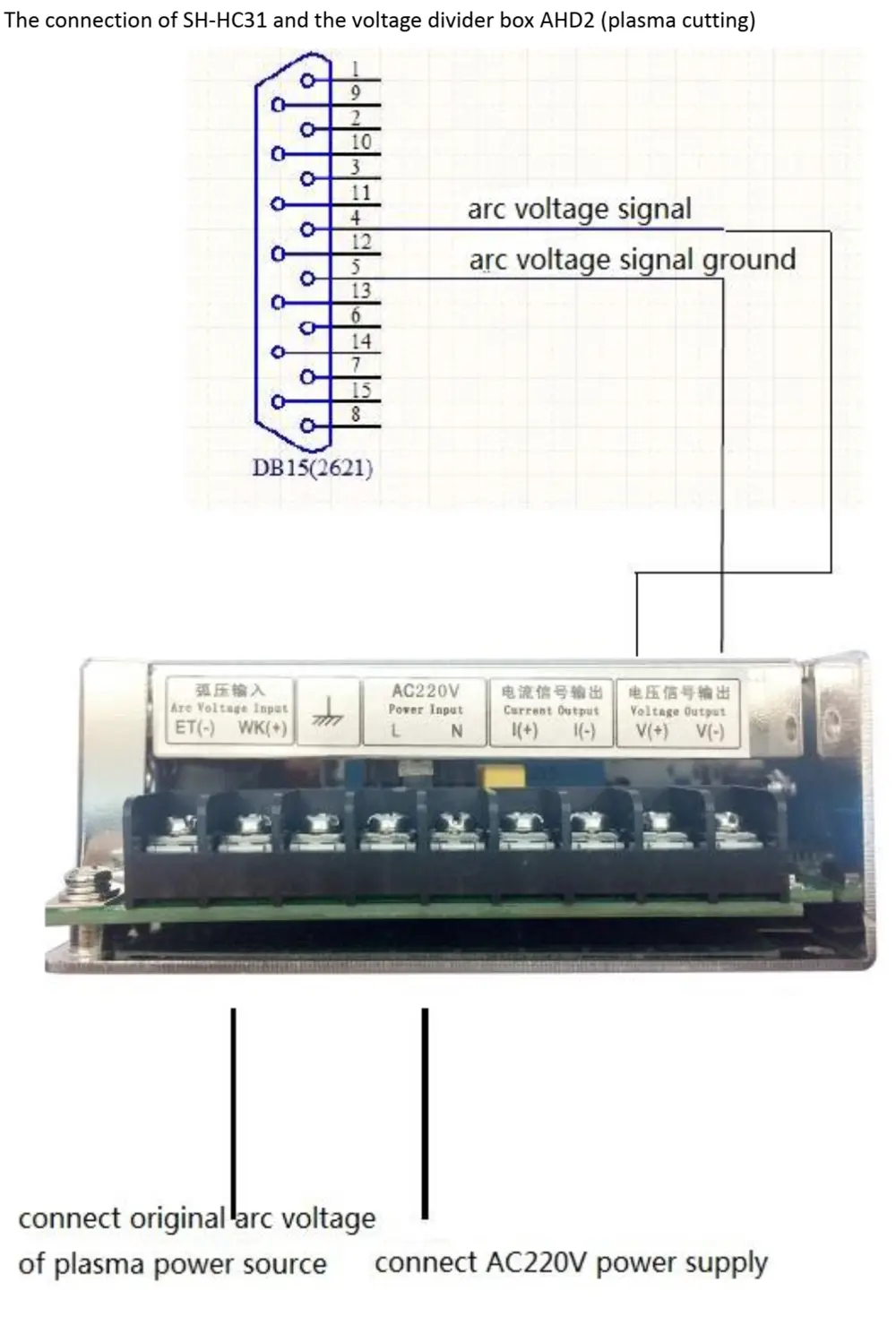

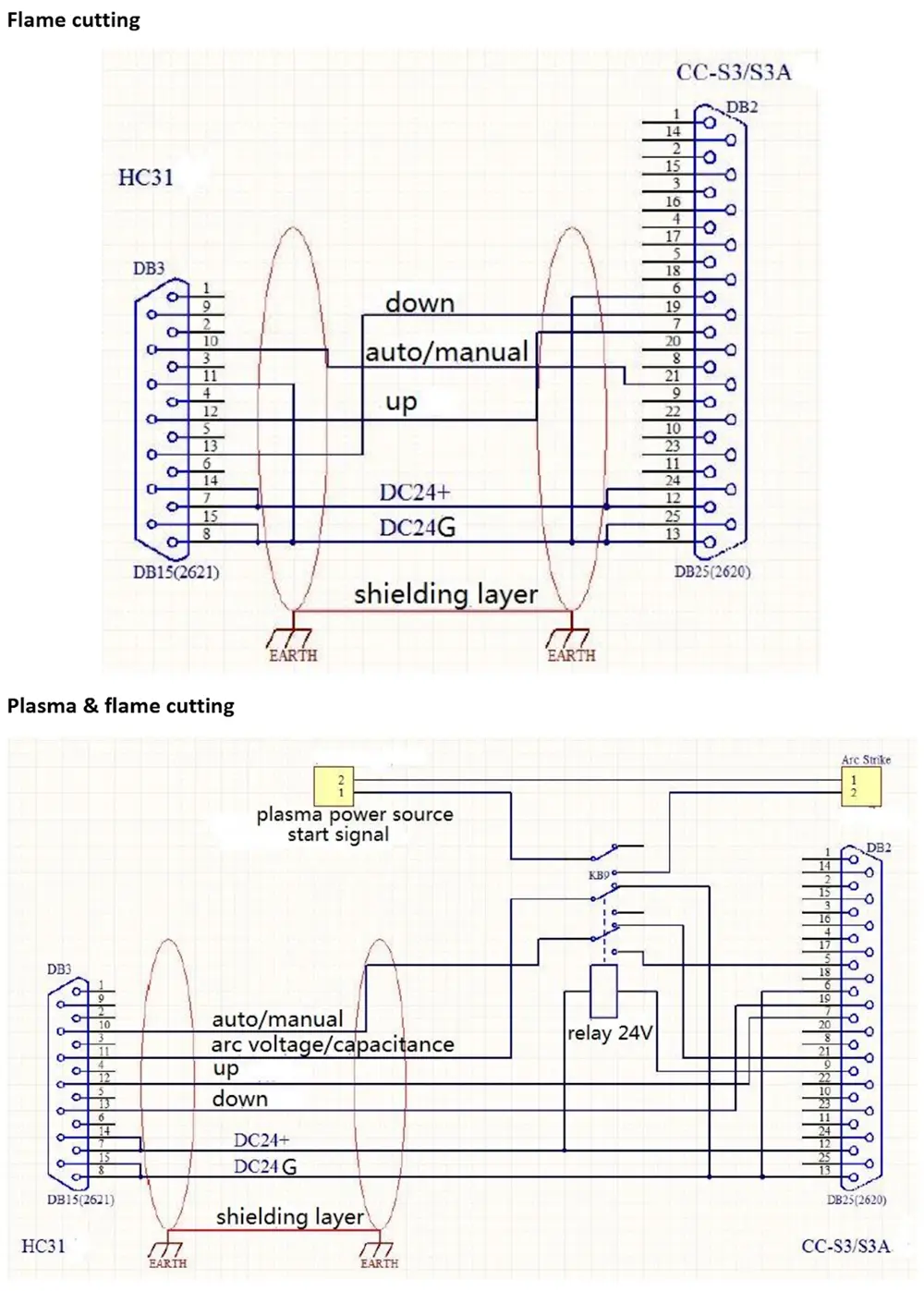

[1]SH-HC31

Details:

- Stepper motor instead of conventional DC motor ,makes it faster and smoother in addition to significantly extended service life.

- Directly displaying the height of the cutting nozzle in capacitance height control mode

- Integration of mechanical lifting device and height controller

- Circuit uses SMD technology without any adjustable devices; all digital control technology ensures high product reliability.

- The feature of "one-keystroke height calibration" guarantees that in any circumstances, the user only needs to press one key to calibrate the absolute height measurement and achieve linear height measurement.

- The shell uses tamper-proof, waterproof and moisture-proof aluminum box sealed design, particularly applicable to the severe environment

- The interface is simple and easy to control. It is suitable for any flame cutting and plasma cutting CNC system or using alone.

- Asynchronous communication function enables connection with CNC system and facilitates parameter setting, automatic/manual control, taper angle transition control and data exchange

Technical Specifications

Type | Data |

Input Voltage | DC 24V±2 V |

Rated Current | 3 A |

Applicable motor | 17/23 HS series of stepper motors |

Manual adjustment range | 0-100 mm |

Automatic height control range | 2 -30 mm |

Adjusting speed of automatic height control | 3000 mm/min (30 ° slope) |

Control precision | ±0.5 mm |

Dimensions of box body | (155 × 87 × 71) mm |

Total weight of capacitance height control | 1.990kg |

Total weight of arc voltage height control | 1.645kg |

Detection system | capacitance height detector and arc voltage height detector |

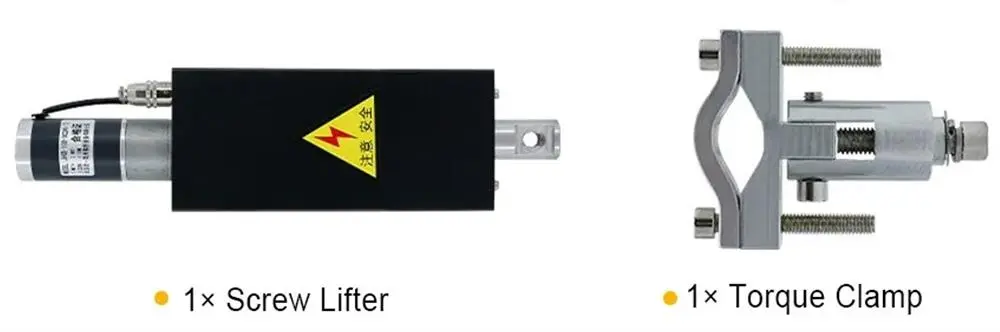

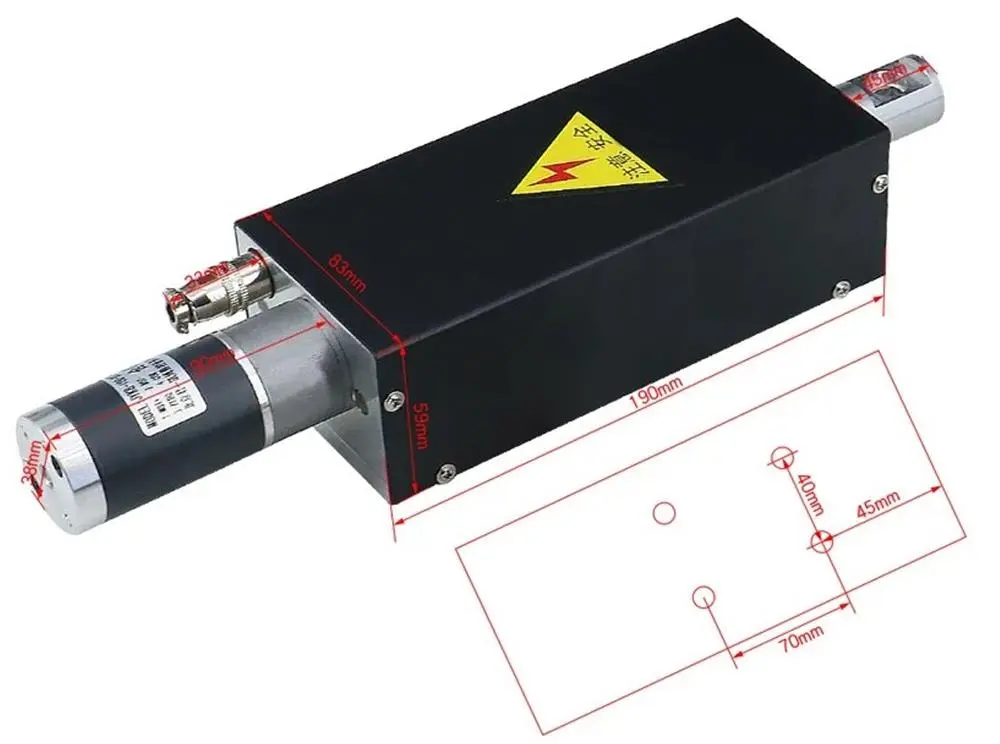

📄Plasma torch lifter

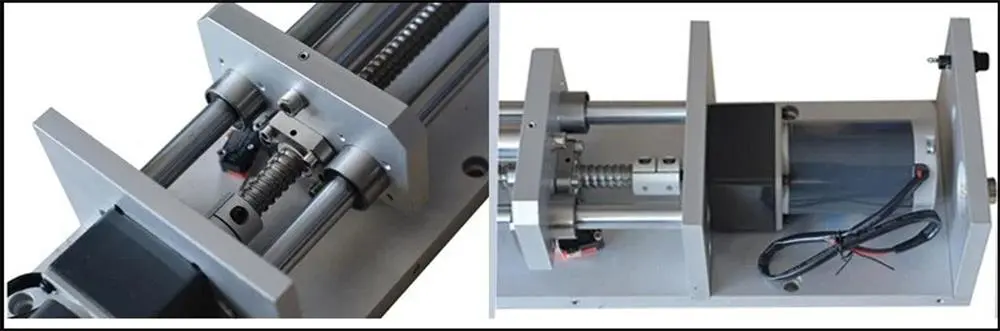

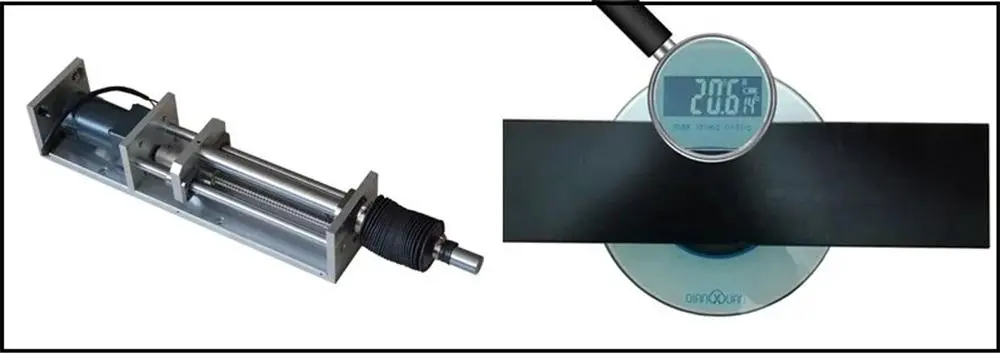

[1]100mm lifter

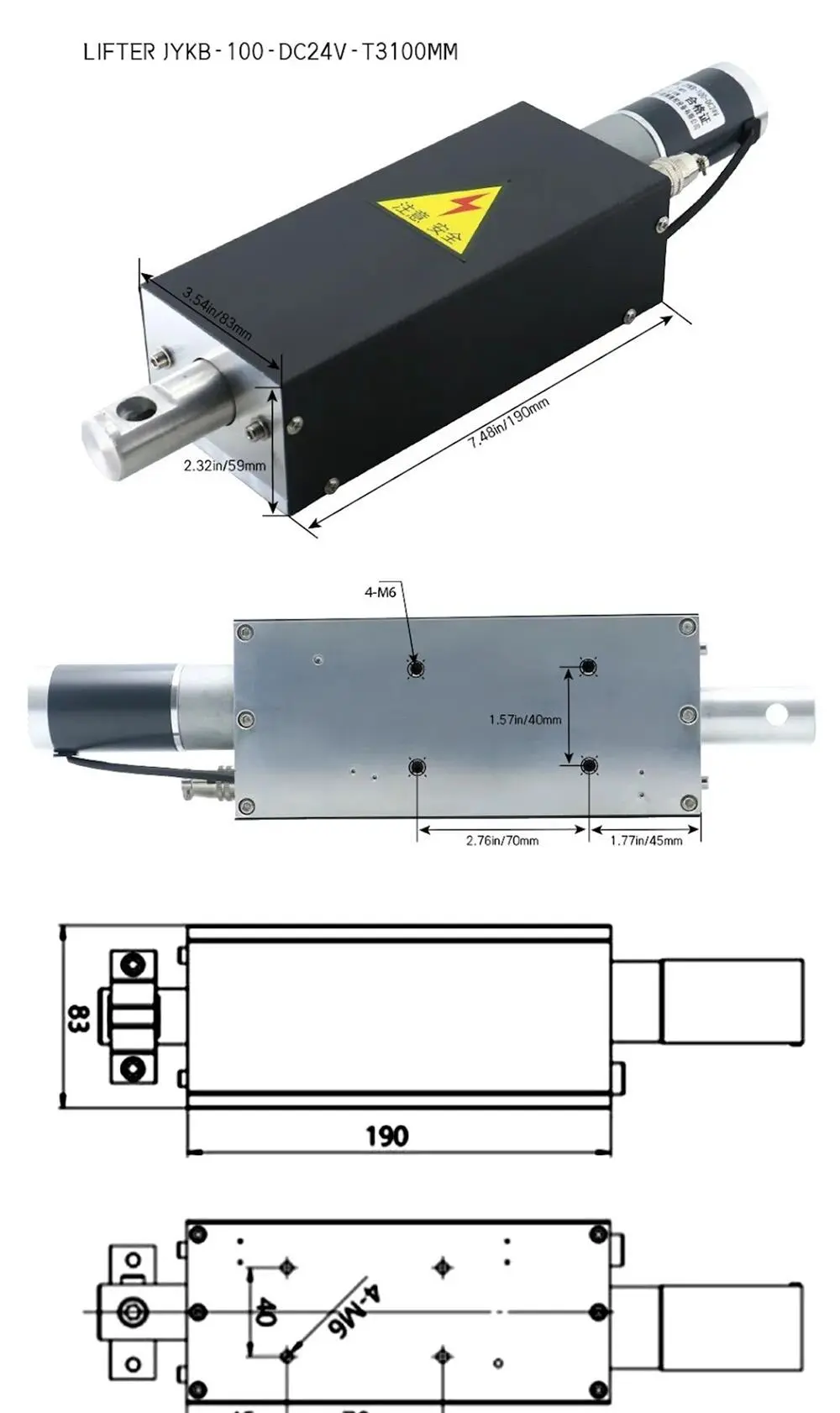

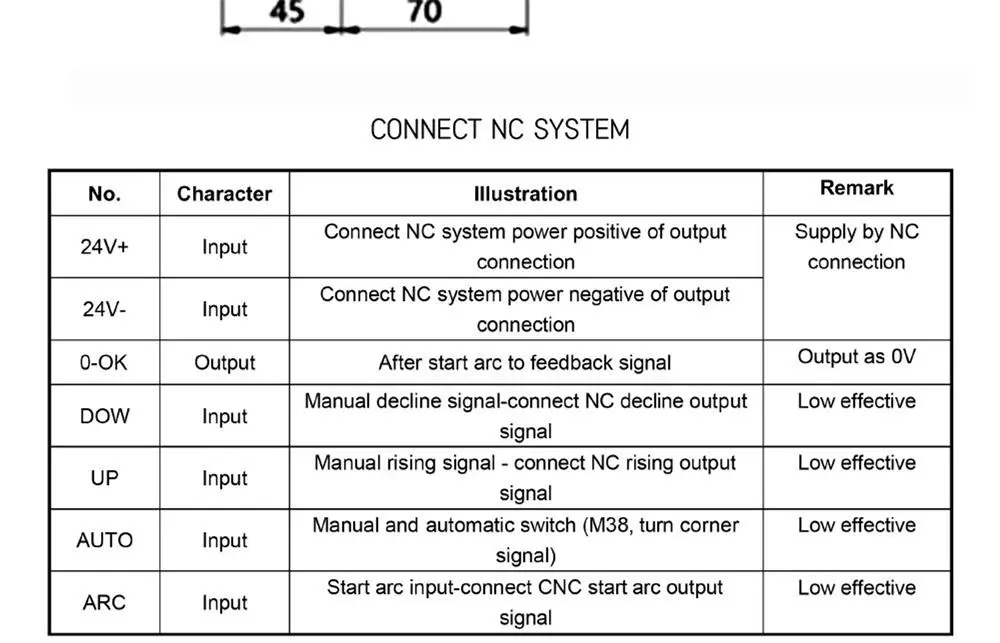

Model①:JYKB-100-DC24V, 1600mm/min,suitable for plasma and flame cutting machine

Model②:JYKB-100-DC24V-T3, 2400mm/min,only suitable for plasma cutting machine

Application:Portable/desktop light-duty CNC flame/plasma cutting machine.

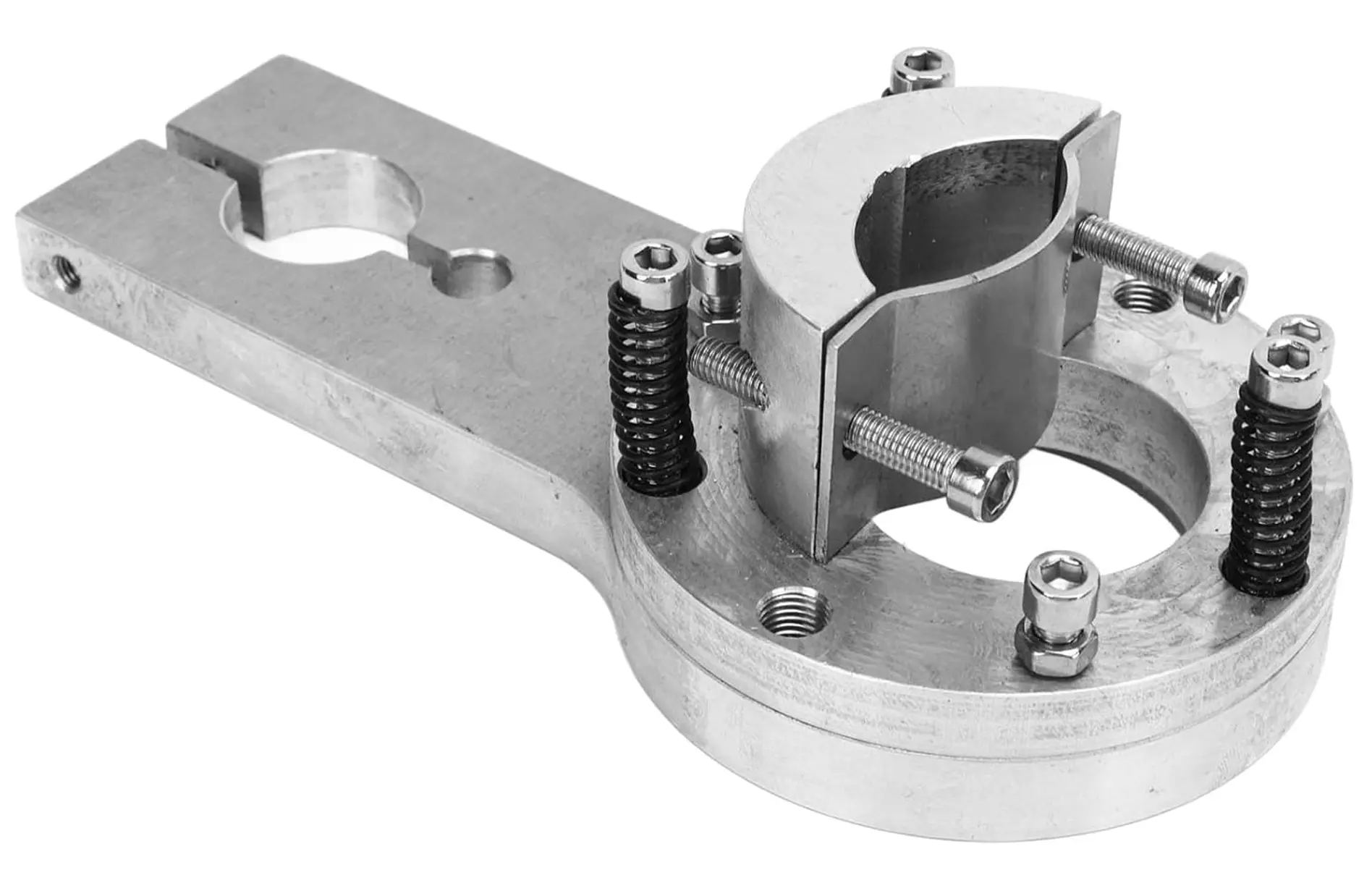

Description:

- This flame/plasma cutting machine Z-axis torch lifter is driven by DC gear motor to lift the torch up & down

- The most important part of the device, which is to keep the machine's cutting accuracy and to support plasma arc positioning function, is equipped with NPN proximity switches

- This lifter's mechanical movement part is made of Taiwan TBI ball screw, standard linear shaft(SFC) & linear slider on the ends; torch clamper/holder is made of bearing steel, and fastened by linear sliders, which is to ensure the lifter movement's stability & verticality

- Convenient to install, work simple, improving the work efficiency

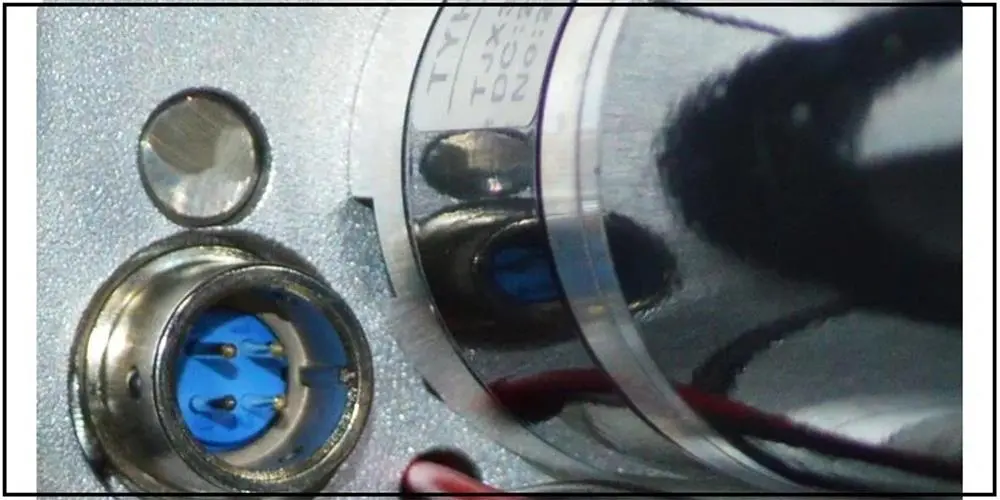

Air control plug definition:1 foot --D +; (motor positive)2 feet --D -; (motor negative)3 feet --Zero; (positioning normally open output)4 feet --COM; (positioning normally open output)Note: Built-in limit (reverse diode)

Parameter:

- T-304 stainless steel screw

- Includes jig (torch range 12mm-38mm)

- Lift inside a plasma arc positioning

- Aluminum body, the upper and lower aluminum sheet thickness of 8mm, forming a processing center

- Four-core plug

- Colour: black spray housing

- Working stroke: 100mm

- Working voltage: DC24V

- Bearing weight: 3 kg

- Dimensions: length 320 * W 80 * H 60

- Mounting Hole Size Length: center distance between two holes 40mm

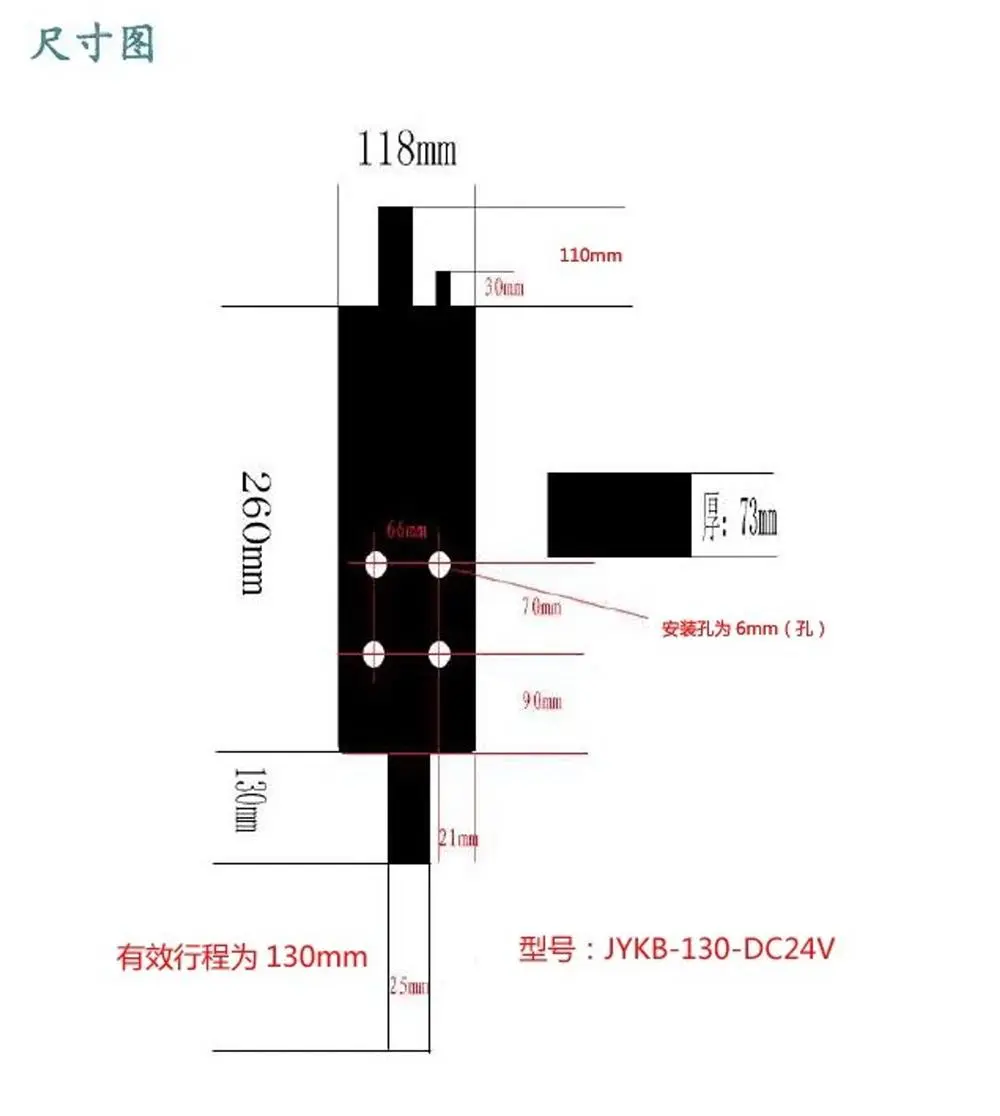

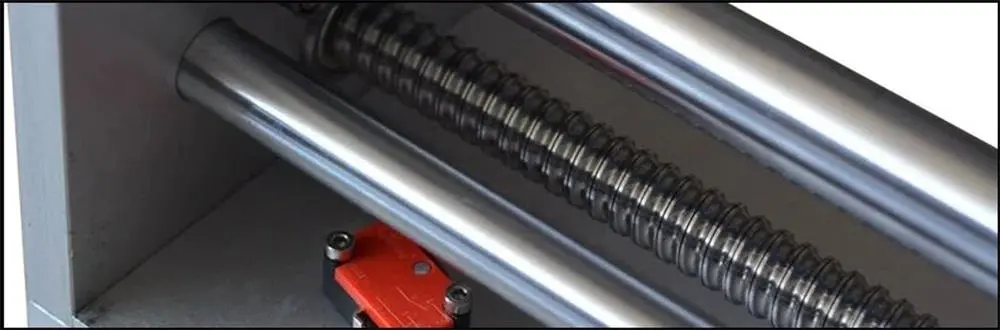

[2]130mm lifter

Model①:JYKB-130-DC24V-GH, 1000mm/min,suitable for plasma and flame cutting machine

Model②:JYKB-130-DC24V-T3, 2400mm/min,only suitable for plasma cutting machine

Introduction:Lifting regulating device: fine plasma cutting machine equipment lifting device is the most preferred product of peers, our company Beijing Junyi Kaibo number control rise and drop adopts deceleration DC motor, drive the torch raising, which affects the critical part of the whole machine cutting accuracy, supports CNC The plasma cutting position function is internally opened. The lifting internal lifting drive uses the Taiwan TBI ball screw, and the optical axes and linear slides are used in both ends, and the colloidal torracene is stabilized by the line slider. Therefore, it is ensured that the verticality of the verticality and reliable verticality is simple and reliable: the rising and falling transmission of flames and plasma cutting; integrally uses aluminum materials to be purified by the machining center, the accuracy is very high, the positioning switch and the limit switch use Taiwan original HIGHLY (after 3C certification and CE certification).

Parameters:

- Taiwan TBI ball screw

- CNC flames and plasma lift can be equipped with anti-striker clamp

- liter, there is a plasma positioning micro switch

- Four-core aviation plug

- telescopic axis is the optical axis and straight slide stable

- Color: shell black (spray)

- Working stroke: 130mm

- Working voltage: DC24V

- carrying weight: 6 kg

- Collaps hole: 20mm-40mm (angle can be fine)

- telescopic hood: high temperature resistant material

Availability Plug Wiring Definition:

- 1 foot -mot +; (motor positive)

- 2 foot --mot -; (motor negative)

- 3 foot - ZERO; (positioning normally open zero point signal output)

- 4 foot --com; (positioning normally open COM signal output)

Note: Lifting body built-in limit (using 10A reverse diode) is not worried about you.

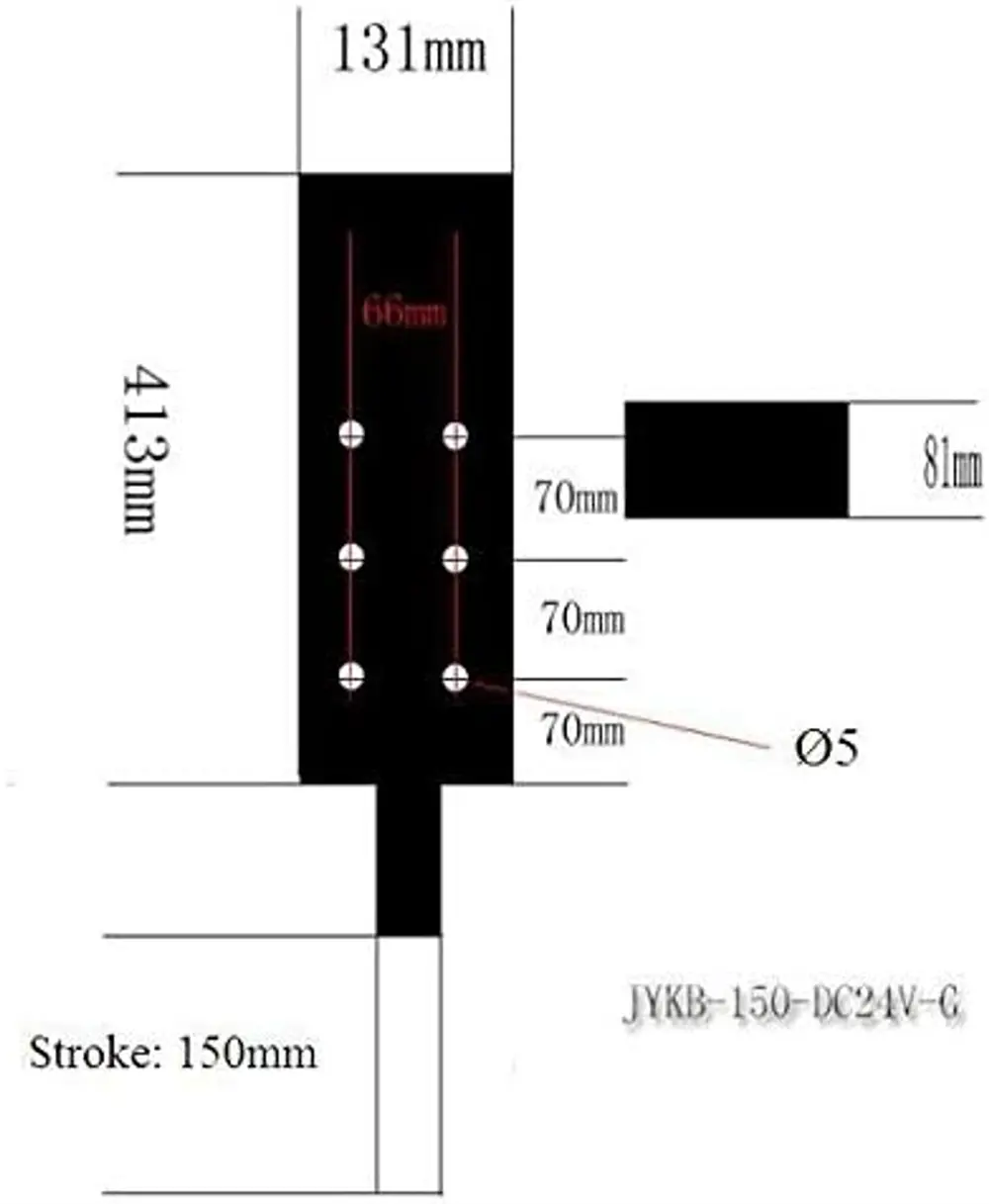

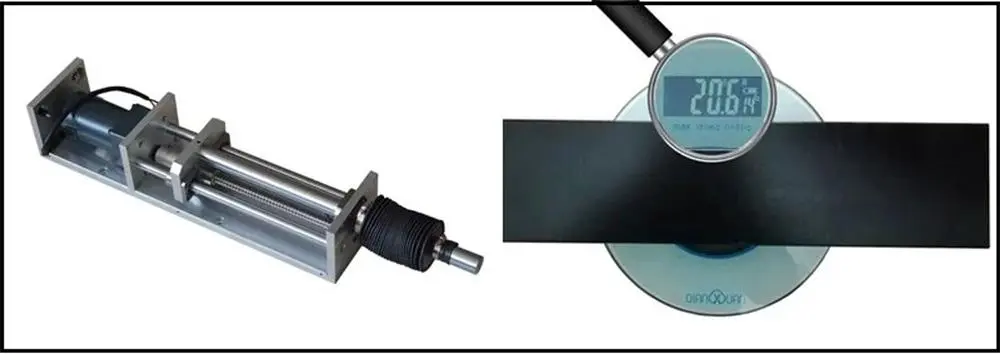

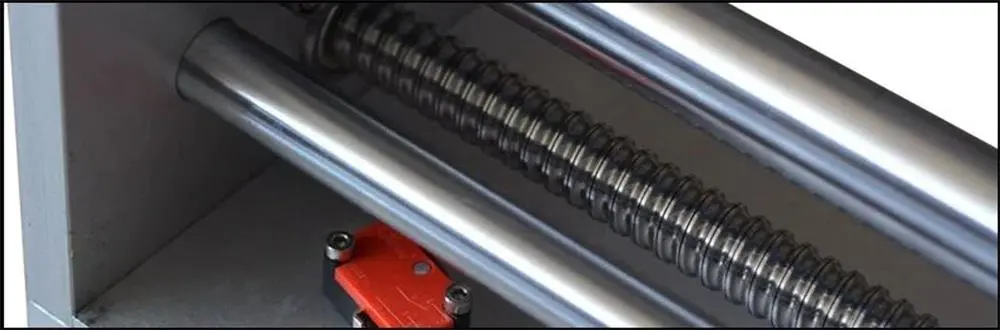

[3]150mm lifter

Model①:JYKB-150-DC24V-GH, 1250mm/min,suitable for plasma and flame cutting machine

Model②:JYKB-150-DC24V-GD, 2150mm/min,only suitable for plasma cutting machine

Packing details:

- JYKB-150-DC24V-GH/GD lifter*1pc

- 4 pin plug*1pc

- standard normal Clamp *1pc

Specifications and features of CNC flame and plasma lifter- Z axis:

- Taiwan TBI ball screw

- CNC flame and plasma collision avoidance gun function

- With plasma positioning micro switch Inside the lifting body

- 4-pin air plug

- The telescopic shaft is optical and the straight sliding block is stable

- Shell color: Black (spray)

- working speed: 1250mm/min

- Working travel: 150mm

- Working voltage: DC24V

- Load Weight: 10 kg

- Clamp gun hole: 20mm-36mm (angle adjustable)

- Retractable cover: high-temperature resistant material

- Size: L 445* W 130* H 80

- Mounting hole size length 707070 width 66

Definition of air plug:

- 1 foot --MOT+; (motor anode)

- 2 foot --MOT-; (motor cathode)

- 3 foot --Zero; (location normally open -zero signal output)

- 4 foot --COM; (location normally open -COM signal output)

- Note: the lifting body built-in limit (10A reverse diode) doesn't need your connection.

1)We adopt TBI Ballscrew ,(other sellers using SS T screw) ,Ballscrew has very less backlash, ensure the positioning accuracy ,also lifter can move with higher speed

2) The aluminium alloys to make sure machine is strong structure, 15mm thickness

3)Build-in Limit switches for up and down, and IHS switch for initial height sensing

4)Aviation Plug Wiring:

Pin 1--D+ (Motor +)

Pin 2--D- (Motor -)

Pin 3--Zero(Initial positioning Output)

Pin 4--Com(Initial positioning Output)

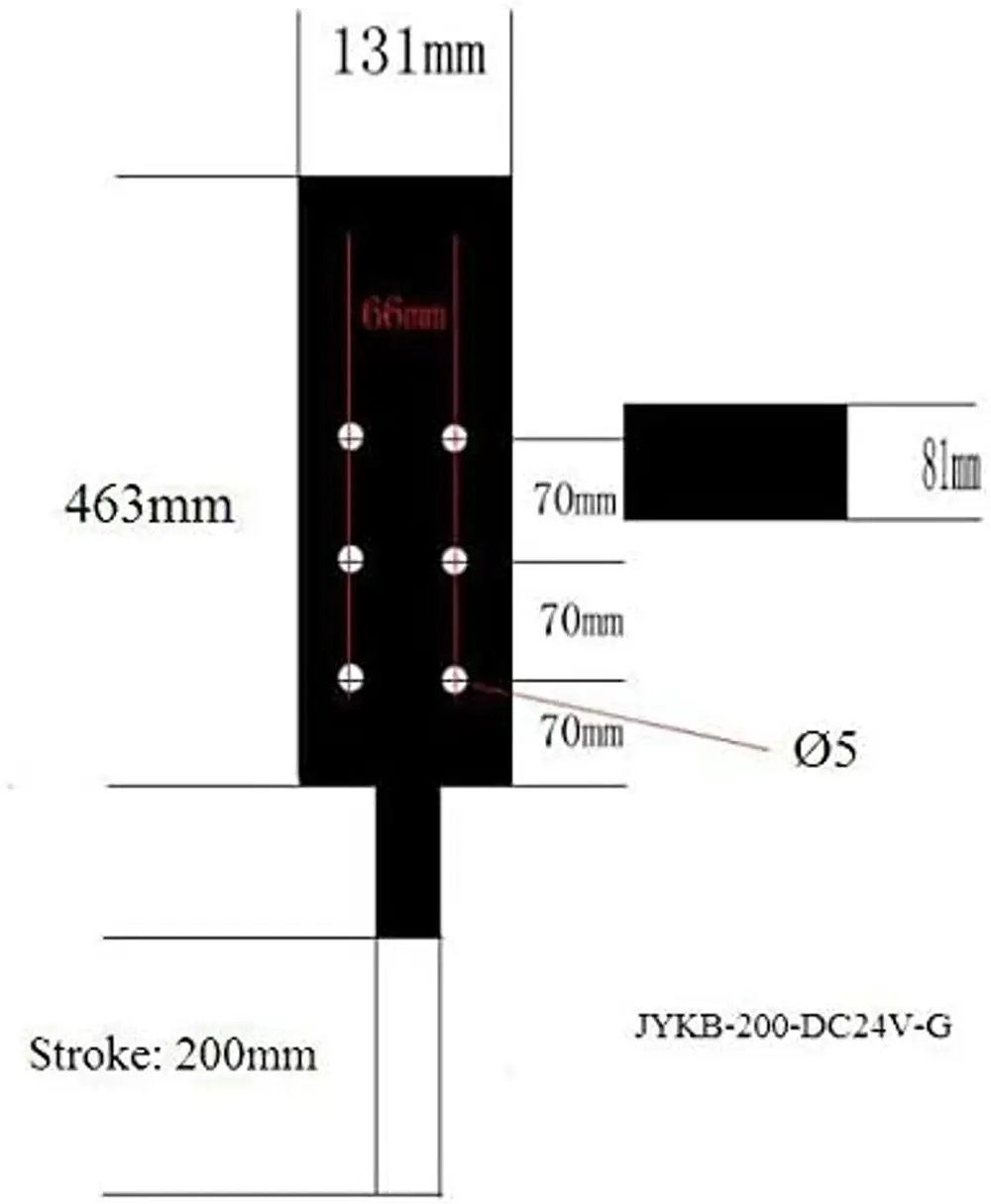

[4]200mm lifter

Model①:JYKB-200-DC24V-GH is suitable for flame and plasma cutting 1250mm/min

Model②:JYKB-200-DC24V-GD is suitable for plasma cutting 2150mm/min

Packing details:

- JYKB-200-DC24V-GH/GD lifter*1pcs

- 4 pin plug*1pcs

- standard normal Clamp 1pcs

Specifications and features of CNC flame and plasma lifter- Z axis:

- Taiwan TBI ball screw

- CNC flame and plasma collision avoidance gun function

- With plasma positioning micro switch Inside the lifting body

- 4-pin air plug

- The telescopic shaft is optical and the straight sliding block is stable

- Shell color: Black (spray)

- working speed: 1250mm/min

- Working travel: 200mm

- Working voltage: DC24V

- Load Weight: 10 kg

- Clamp gun hole: 20mm-36mm (angle adjustable)

- Retractable cover: high-temperature resistant material

- Size: L 445 W 130 H 80**

- Mounting hole size length 707070 width 66

Definition of air plug:

- 1 foot --MOT+; (motor anode)

- 2 foot --MOT-; (motor cathode)

- 3 foot --Zero; (location normally open -zero signal output)

- 4 foot --COM; (location normally open -COM signal output)

Note: the lifting body built-in limit (10A reverse diode) doesn't need your connection.

1)We adopt TBI Ballscrew ,(other sellers using SS T screw) ,Ballscrew has very less backlash, ensure the positioning accuracy ,also lifter can move with higher speed

2) The aluminium alloys to make sure machine is strong structure, 15mm thickness

3)Build-in Limit switches for up and down, and IHS switch for initial height sensing

4)Aviation Plug Wiring:

Pin 1--D+ (Motor +)

Pin 2--D- (Motor -)

Pin 3--Zero(Initial positioning Output)

Pin 4--Com(Initial positioning Output)

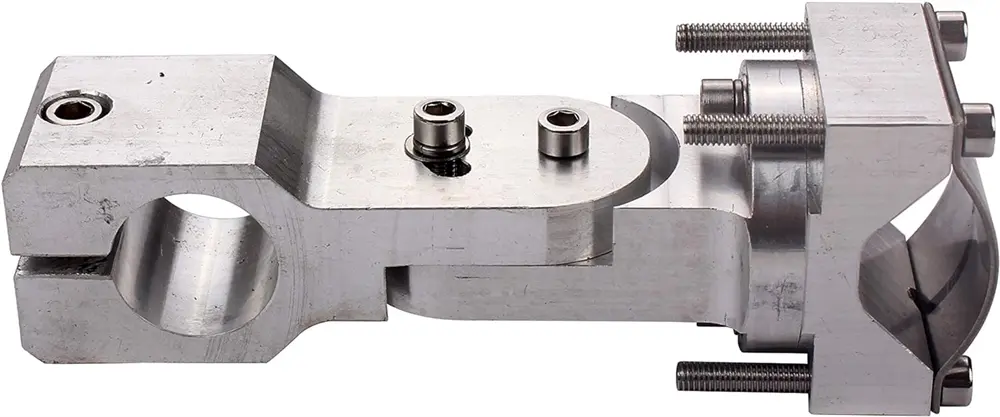

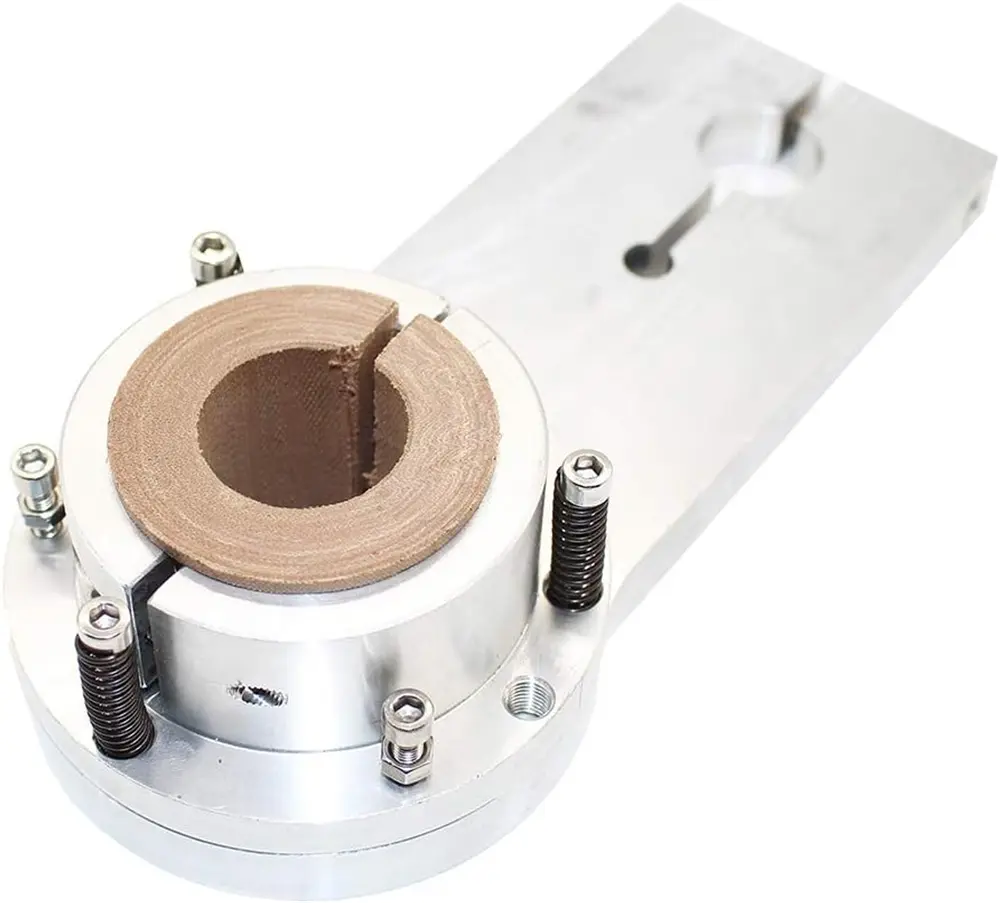

[5]Anti-collision fixture

type A 20-35mm torch gun

type B 32-55mm torch gun

type C rotatable:35/40/45/50mm

📄Plasma nesting software

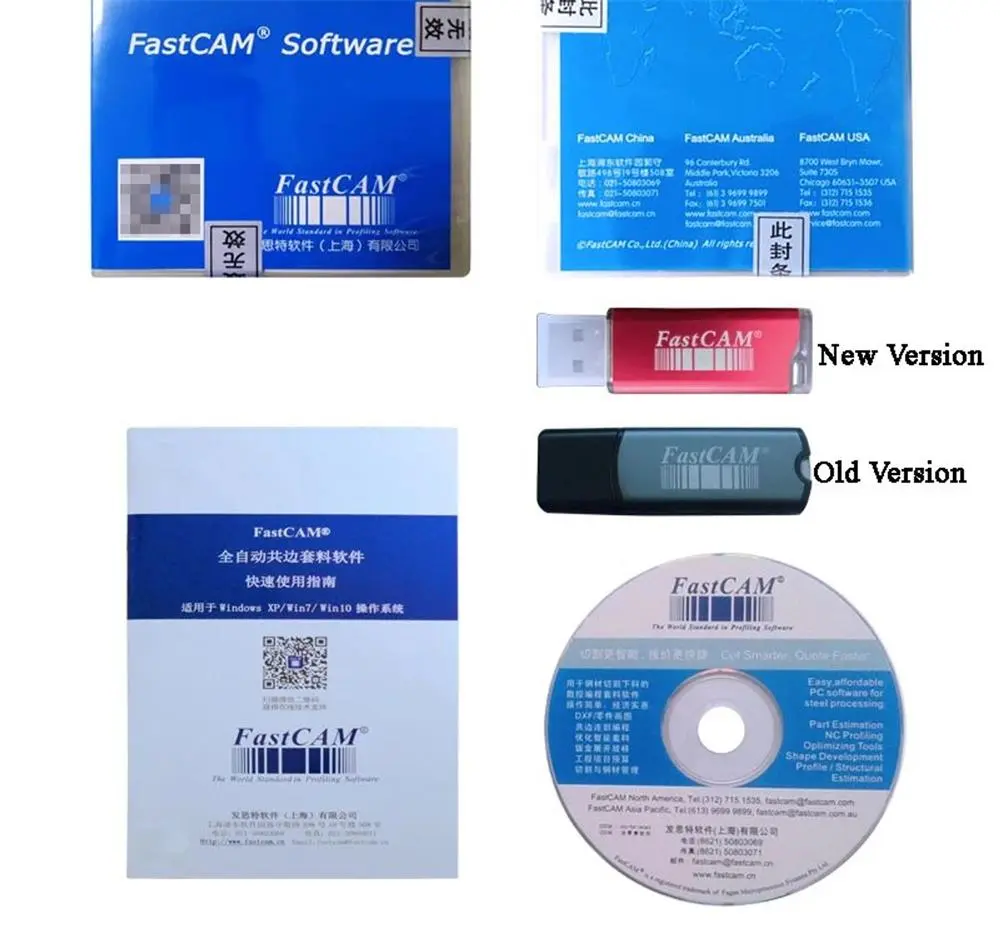

[1]FASTCAM

Attention:Fastcam software has 3 kinds

- Fastcam standard version:It has no size limit for sheets, and it supports manual nesting only.

- Fastcam Professional portable version:size limit is 6000*1800mm.

- It has the functions such as automatic nesting and bridging.

- This version is very economical for smaller cutting machine

- Fastcam professional version:without size limit

FastCAM software has four modules for CNC cutting:

FastCAM drawing module:

- Draw: similar to CAD, to draw all kinds of parts

- CAD compatible and Optimizer: to read in and optimize DXF/DWG files by delete, compress, extract, explode

- Cutting functions: Kerf compensation, plasma bridge, common line cutting, corners, CAD layers, word label

FastNEST automatic nesting module:

- Manual nesting, easy & convenient to use

- Automatic nesting in a row or in a matrix

- Full automatic nesting

- Interactive nesting by auto and manual nesting

- Common cut & continue cut to reduce pre-pierce

- Remnant nesting for irregular remnant or parts

FastPATH automatic pathing module:

- Programming: automatic & manual pathing include marking, path optimizer, multi-layer cutting

- Support multiple CNC control, ESSI&EIA G/M code

- Support Kerfs comp., pre-pierce, stitch& tag cutting

FastPLOT verification module:

- NC Verification: automatic & manual stimulation, dimension and kerf compensation verification

- Costing: utilization, cut length, pierce & cutting cost

- Transfer NC files to CAM/DXF/DWG files

Main Features

- Easy to operate, complete training courses, training demonstrations and accelerated textbooks

- Full-featured, covering the whole process of drawing, nesting, programming, cutting and verification

- The nesting function is perfect, from manual, automatic, matrix, automatic tightening, to manual automatic interactive nesting, fully combining the experience of human nesting and the computing speed of the computer.

- Fully automatic edge nesting cutting to improve nesting utilization and save steel

- Residual material nesting management, effectively saving and recycling the remaining steel plates

- Bridging and continuous cutting to improve cutting efficiency, effectively avoid or reduce preheating and perforation, save consumables, especially reduce plasma cutting nozzles and electrodes

- At the same time support multiple cutting machines of different brand controllers, such as FastCNC, Burny, EDGE, Fagor, start, etc.

- Full support for Windows 98/2000/NT/XP/VISTA, WIN7, WIN8 operating systems

- Support multi-language environment: multi-language software platform with up to ten different languages, Chinese, English, German, Japanese, French, Spanish, Korean, Russian and other ten languages (requires order).

[2]STARCAM

Description

- STARCAM software is suitable for cutting the Star Peak system, Star system, Fangling system, Hypertherm system, etc. The software can automatically typeset, common edge cutting, and the size of the steel plate is not limited and can be set arbitrarily.

- Portable, small bee cutting machine, desktop, gantry cutting machine can be used.

- New STARCAM CNC Plasma Cutting Machine Nesting Software ENGLISH Language No Size Limit.

- 100% genuine!!! Ensure genuine products and eliminate piracy!

Packing of CNC system new software version is as follows:USB dongle (gold)*1pcSoftware version 4.7 installation file download website Contact customer service to get

STARCAM software has four modules for CNC cutting

STARCAM drawing module:

- Draw: similar with CAD, to draw all kinds of parts

- CAD compatible and Optimizer: to read in and optimize DXF/DWG files by delete, compress, extract, explode

- Cutting functions: Kerf compensation, plasma bridge, common line cutting, corners, CAD layers, word label

NEST nesting module:

- Manually nesting, easy & convenient to use

- Manually nesting in a row or in a matrix

PATH automatic pathing module:

- Programming: automatic & manual pathing include marking, path optimizer, multi-layer cutting

- Support multiple CNC control, ESSI&EIA G/M code

- Support Kerfs comp., pre-pierce, stitch & tag cutting

PLOT verification module:

- NC Verification: automatic & manual simulation, dimension and kerf compensation verification

- Costing: utilization, cut length, pierce & cutting cost

- Transfer NC files to CAM/DXF/DWG files

Features:STARCAM Support: win10, win8, win7, XP; 32-bit, 64-bit operating systems can be used!STARCAM drawing nesting software: It consists of three modules: drawing module (StarCAM), nesting module (StarCUT) and numerical control code simulation module (StarTEST). Each module can run independently and can also call each other. Support NC programming of various CNC cutting controllers.

- The drawing module can complete the operations of drawing, editing, scaling, copying, arraying, rotating, etc. of the cutting parts; supporting the import, editing and exporting of CAD graphics files (such as CAM, DXF, DWG, IGES) in other formats, and supporting users Library management; can optimize the CAD graphics. It can generate cutting paths and machining codes required for CNC machining of parts.

- The nesting module can complete the batch parts nesting of multiple parts on the rectangular plate or the residual material plate, support short-line continuous cutting, co-edge and bridging technology, reduce the number of perforations, improve the utilization rate of the plate, fast and efficient, support manual Nesting, matrix nesting, interactive nesting and residual nesting, and can quickly generate the numerical control codes required by a variety of numerical control cutting equipment.

- The simulation module can carry out computer graphics simulation of the NC codes generated by the above two modules, and can run step by step and track step by step. It supports the editing and modification of NC codes during the simulation process, which can verify the correctness and rationality of NC codes and improve production efficiency. , And can estimate the processing cost.

Last update: 2024